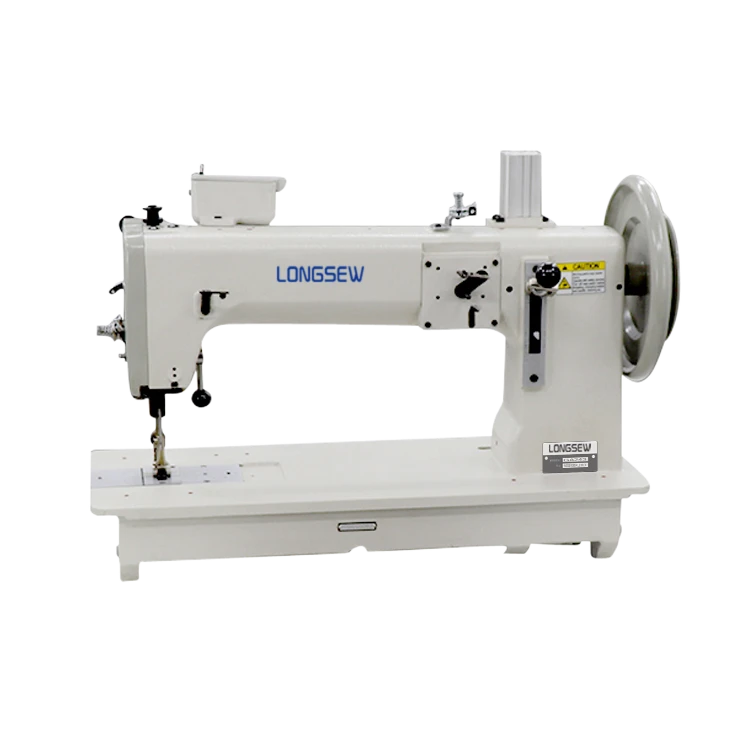

rigging sewing machine

The Versatility of Rigging Sewing Machines

In the ever-evolving world of textiles and fashion, sewing machines have become indispensable tools that transform raw fabrics into exquisite garments and items. Among the various kinds of sewing machines, rigging sewing machines hold a special place due to their unique capabilities and extensive applications, particularly in industries requiring robust stitching solutions.

Rigging sewing machines are primarily designed for heavy-duty stitching, making them ideal for work with thick materials such as canvas, leather, and various types of outdoor fabrics. Such machines are vital in industries that manufacture sails, tarpaulins, awnings, and even parachutes. The rigging aspect of these machines refers to their ability to handle the rigors of creating structures or items that have to endure substantial tensile strength, weather elements, and operational stress.

Key Features of Rigging Sewing Machines

1. Heavy-Duty Construction Rigging sewing machines are built with durable materials to withstand the strain of sewing through heavy fabrics. They often feature reinforced frames and components that enhance their stability and longevity.

2. Powerful Motors To penetrate thick layers of material, these machines are equipped with powerful motors that provide the necessary torque. This allows for swift stitching without the risk of the machine jamming or breaking needles, which is a common issue in conventional sewing machines.

rigging sewing machine

3. Versatile Stitching Options Many rigging sewing machines offer a variety of stitching options, including straight, zigzag, and heavy-duty overlock stitches. This versatility enables users to perform various tasks, from simple hems to complex seam constructions.

4. Specialized Feet Rigging sewing machines often come with specialized presser feet designed for different types of fabric. For example, walking feet are used for layers that tend to slip, ensuring a consistent and even feed through the machine.

Applications in Various Industries

Rigging sewing machines are extensively used in several sectors. In the marine industry, they are crucial for sewing sails and covers that must be both durable and water-resistant. Similarly, in the camping and outdoor equipment sector, these machines are responsible for manufacturing tents and gear that withstand harsh weather conditions. Moreover, in the fashion industry, rigging sewing machines have found a niche in high-end leather goods production, where the quality of stitching can significantly impact the product's aesthetic and functional appeal.

Conclusion

The importance of rigging sewing machines cannot be overstated, as they play a critical role in a variety of industries requiring heavy-duty stitching. Their robust construction, powerful motors, versatile stitching options, and specialized attachments make them invaluable assets for businesses that demand quality and durability in their products. As industries continue to grow and evolve, the rigging sewing machine will undoubtedly remain at the forefront, driving innovation and craftsmanship in textile manufacturing. Whether in the hands of an experienced artisan or a large-scale production facility, the rigging sewing machine is an essential tool that exemplifies the perfect blend of functionality and resilience.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025