PP Woven Bag Stitching Machine for Efficient Production and Durable Seams

The Evolution and Importance of PP Woven Bag Sewing Machines

In today’s fast-paced manufacturing world, efficiency and quality are paramount, especially in the production of packaging materials. One significant advancement in this realm is the introduction of PP (Polypropylene) woven bags, which have surged in popularity due to their durability, versatility, and eco-friendliness. Central to the production of these bags is the PP woven bag sewing machine, a specialized piece of equipment that ensures these bags are constructed efficiently and robustly.

What are PP Woven Bags?

PP woven bags are made from polypropylene, a type of plastic that is lightweight yet strong. These bags are commonly used in agriculture, construction, and retail due to their ability to carry heavy loads while remaining resistant to moisture and chemicals. The increasing demand for these bags has led to a corresponding rise in the need for advanced sewing machines specifically designed for weaving these materials.

The Role of Sewing Machines in Production

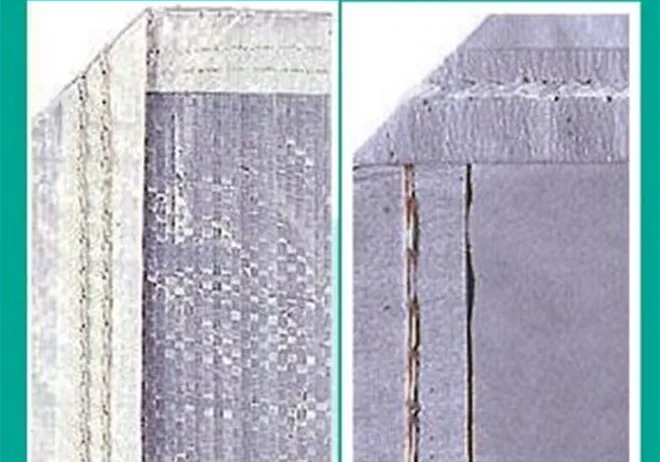

Sewing machines used for PP woven bags are not just ordinary sewing machines. They are engineered to handle the unique properties of polypropylene fabric, which can be challenging to work with due to its slick surface and stiffness. These machines are equipped with high-speed sewing capabilities and specialized needles and threads that can penetrate the thick, woven fabric without breaking. Moreover, they often incorporate features that enhance the sewing process, such as automatic tension adjustments and programmable settings, allowing for rapid and consistent production.

Key Features of PP Woven Bag Sewing Machines

1. High Speed and Efficiency Modern PP woven bag sewing machines can operate at impressive speeds, significantly increasing production rates. This is crucial for manufacturers who need to meet large orders and tight deadlines.

pp woven bag sewing machine

2. Durability and Strength These machines are built to withstand the rigors of industrial use, providing reliable performance over time. The construction materials used in these machines ensure they remain operational under heavy workloads.

3. Versatility Many sewing machines are equipped with multiple functionalities that allow manufacturers to produce different types of bags, including flat and gusseted bags. This versatility enables businesses to cater to a wider range of customer needs.

4. User-Friendly Operation With advancements in technology, many machines now feature digital controls, automated threading systems, and intuitive interfaces that simplify the training of operators and reduce the risk of human error.

5. Quality Assurance High-quality sewing machines offer features like stitch monitoring to ensure that each bag is sewn to perfection, minimizing defects that could lead to customer dissatisfaction or product failure in the field.

The Impact on Sustainability

As the world shifts towards more sustainable practices, PP woven bags have become increasingly favored over traditional paper and plastic bags. The sewing machines that produce these bags are designed to promote sustainable manufacturing practices by reducing material waste through efficient design and production processes. Moreover, many sewing machines are capable of utilizing recycled polypropylene, further enhancing the eco-friendliness of the bags produced.

Conclusion

The introduction of PP woven bag sewing machines marks a significant step forward in the manufacturing of durable and versatile packaging solutions. As industries continue to seek more efficient and sustainable ways to package goods, the demand for these specialized machines is likely to grow. By investing in advanced sewing technology, manufacturers can improve their production processes, reduce waste, and better serve their customers’ needs in an increasingly competitive marketplace. The evolution of PP sewn bags and the machines that create them is a testament to the innovative spirit of the packaging industry, driving it towards a more sustainable and efficient future.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025