Long Arm Sewing Machine: Heavy Duty, Industrial & Upholstery

In the demanding world of industrial textile and material fabrication, the efficiency and precision of machinery are paramount. Central to the processing of large, heavy, and often complex materials is the long arm sewing machine. These specialized machines are engineered to tackle projects that standard sewing equipment cannot, offering extended reach, enhanced material handling capabilities, and the robust power required for multi-layered or dense substrates. From automotive upholstery to marine canvas, and from luxury leather goods to protective military gear, the application of these machines is diverse and critical for delivering high-quality, durable finished products. This article delves into the technical intricacies, market trends, and practical applications of these essential industrial tools, emphasizing their role in modern manufacturing.

Industry Trends and the Evolution of Heavy-Duty Sewing Technology

The landscape of industrial sewing is continuously evolving, driven by demands for greater efficiency, higher quality, and the ability to process new, advanced materials. Key trends influencing the development of the long arm sewing machine segment include:

- Automation and Digitization: Integration of programmable stitch patterns, automatic thread trimming, and material feeding systems to reduce manual labor and increase precision.

- Material Versatility: Development of machines capable of handling an even wider range of materials, from highly elastic composites to extremely rigid and thick leathers or webbing, often requiring specialized needle systems and presser feet.

- Ergonomics and Operator Comfort: Design improvements focusing on reducing operator fatigue, enhancing visibility, and simplifying machine operation to improve overall productivity and safety.

- Sustainability: Energy-efficient motors (servo motors), reduced waste generation, and the use of durable, recyclable components are becoming increasingly important in manufacturing.

- Customization: Growing demand for tailor-made solutions, where machine arm lengths, specialized feed mechanisms, and tooling are customized for specific product lines or material handling challenges.

The market for an industrial long arm sewing machine for sale is expanding as industries like automotive, aerospace, and specialized protective gear manufacturers seek robust and reliable equipment to manage their complex production requirements. The shift towards higher-quality, long-lasting products also necessitates more capable sewing machinery.

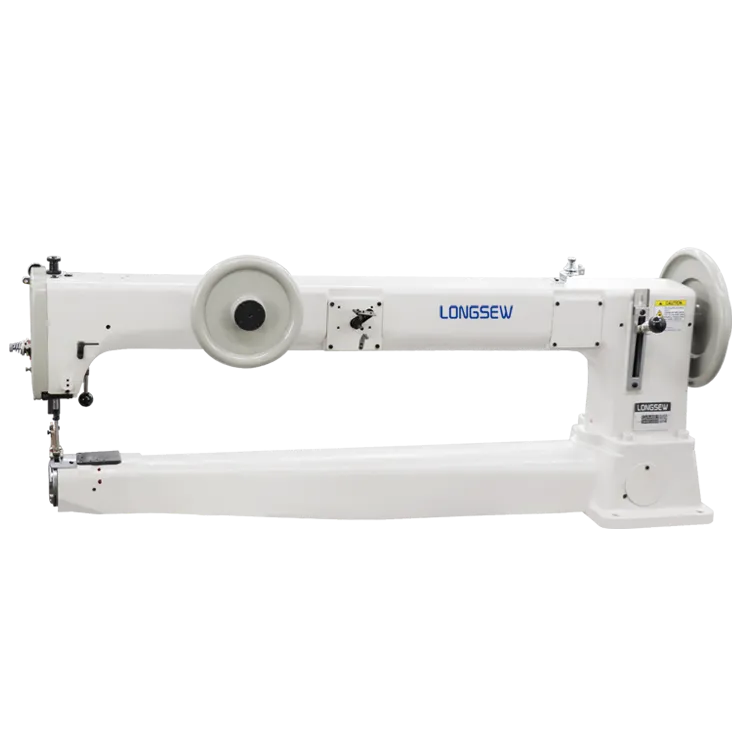

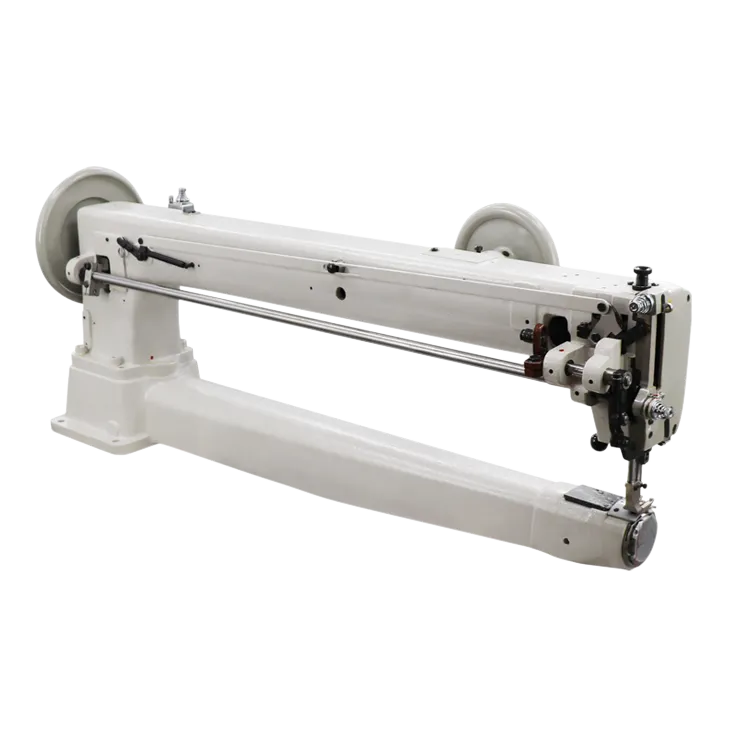

Fig. 1: Advanced industrial sewing operations requiring extended reach.

Manufacturing Process of a High-Performance Long Arm Sewing Machine

The production of a heavy duty long arm sewing machine is a meticulous process, combining traditional engineering principles with advanced manufacturing techniques to ensure durability, precision, and longevity.

Key Stages in Manufacturing:

-

Material Selection and Preparation:

- Frames and Major Components: High-grade cast iron or specialized aluminum alloys are chosen for their exceptional rigidity and vibration damping properties. These materials undergo stringent metallurgical analysis to ensure compliance with international standards.

- Shafts and Gears: Alloy steels, often specified as AISI 4140 or equivalent, are selected for high tensile strength and wear resistance.

- Precision Parts: Stainless steel and hardened tool steels are utilized for elements like needle bars, hooks, and loopers, which demand extreme precision and resistance to wear and corrosion.

-

Core Manufacturing Processes:

- Casting: For machine frames and larger structural components, precision casting techniques are employed, followed by annealing to relieve internal stresses and enhance material uniformity.

- Forging: Critical load-bearing shafts and connecting rods are forged to optimize grain structure, imparting superior strength and fatigue resistance.

- CNC Machining: Advanced multi-axis CNC machines are used for all precision components, ensuring tolerances often within microns. This includes machining of feed dogs, presser feet, and the intricate parts of the sewing head.

- Heat Treatment: Components requiring high hardness and wear resistance undergo controlled heat treatment processes such as carburizing, nitriding, or induction hardening.

- Surface Finishing: Specialized coatings (e.g., hard chrome plating, PTFE coatings) are applied to enhance corrosion resistance, reduce friction, and improve service life, particularly in challenging environments like those found in marine or petrochemical industries.

-

Assembly and Calibration:

- Skilled technicians meticulously assemble components, ensuring precise alignment and optimal mechanical clearances.

- Calibration involves fine-tuning stitch timing, tension, and feed mechanisms to meet stringent performance specifications.

-

Quality Control and Testing Standards:

- ISO 9001:2015 Certification: Adherence to a comprehensive quality management system across all manufacturing stages.

- ANSI/ASME B11.1 Standard: Compliance with safety requirements for industrial sewing machines.

- Performance Testing: Each machine undergoes extensive testing, including continuous operation under maximum load, stitch consistency across different material thicknesses, and noise/vibration analysis.

- Longevity Testing: Components are subject to accelerated life cycle testing to predict and ensure a service life often exceeding 10-15 years under typical industrial use.

Advantages in Typical Application Scenarios:

The meticulous manufacturing process translates directly into superior performance. For industries like heavy textiles, automotive, and marine, these machines offer:

- Energy Efficiency: Modern servo motors provide on-demand power, reducing energy consumption by up to 70% compared to traditional clutch motors.

- Corrosion Resistance: Specialized coatings and material choices ensure prolonged operational integrity, especially crucial in environments with high humidity or exposure to chemicals (e.g., specific manufacturing processes, marine applications).

- Reduced Maintenance: High-quality components and precision engineering lead to fewer breakdowns and extended service intervals.

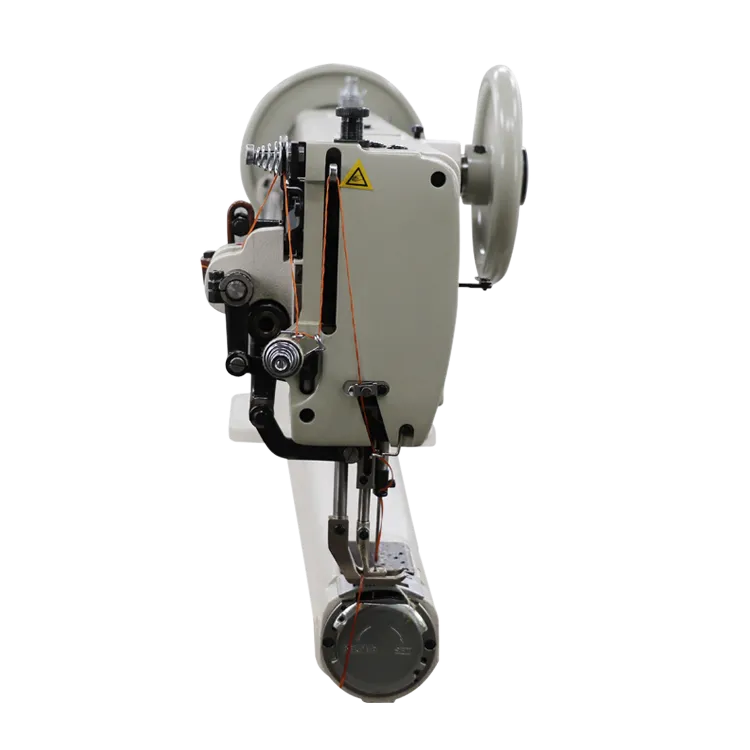

Fig. 2: Precision engineering of internal components for durability.

Technical Specifications: Super Long Arm Extra Heavy Duty Cylinder Bed Sewing Machine GA441-L38

Understanding the technical parameters of a specialized machine like the Super Long Arm Extra Heavy Duty Cylinder Bed Sewing Machine for Big & Thick Material Products GA441-L38 is crucial for B2B decision-makers. This machine exemplifies cutting-edge design tailored for extreme industrial demands.

Key Features and Explanations:

- Super Long Arm Design: Refers to the extended throat space (distance from the needle to the machine body), typically exceeding 25 inches (635mm). This allows operators to easily maneuver very large and bulky materials, reducing the need for repositioning.

- Extra Heavy Duty: Indicates the machine's capacity to sew through multiple layers of dense materials such as industrial webbing, thick leather, canvas, and specialized composites without loss of power or stitch quality. This is achieved through robust feeding mechanisms, powerful motors, and reinforced components.

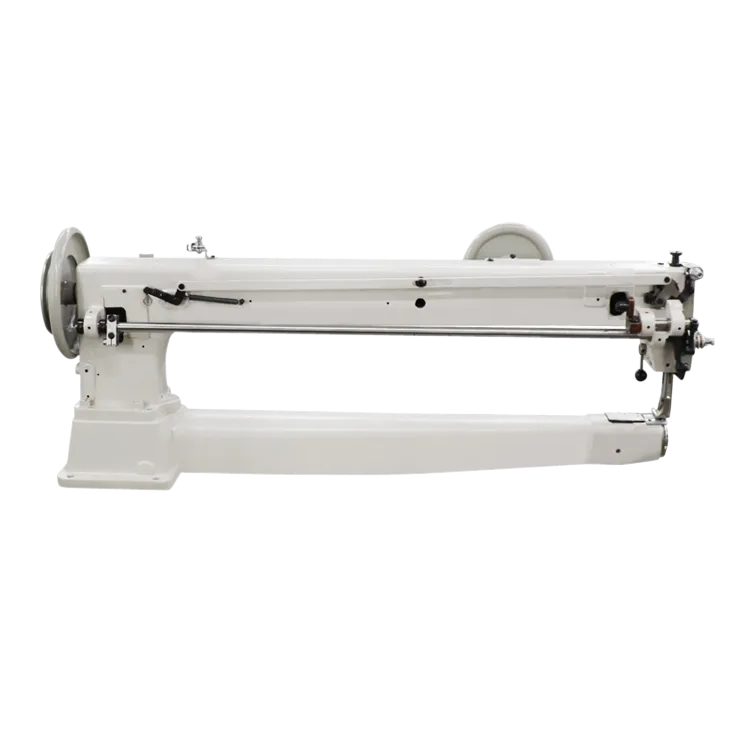

- Cylinder Bed: Instead of a flatbed, the GA441-L38 features a narrow, cylindrical arm that supports the material during sewing. This design is ideal for stitching tubular items (e.g., bags, filters, boots), curved products (e.g., automotive seats, luggage corners), or reaching into confined spaces.

- Triple Feed Mechanism (Walking Foot, Needle Feed, Bottom Feed): This synchronized feeding system ensures that all layers of material are moved together evenly, preventing shifting, puckering, or uneven stitches, especially vital for slippery or thick materials.

Product Specification Table: GA441-L38

| Parameter | Specification (GA441-L38) | Significance for Industrial Use |

|---|---|---|

| Arm Length / Working Space | 950 mm (37.4 inches) | Exceptional reach for very large or complex items like boat covers, tarpaulins, or oversized upholstery panels. |

| Cylinder Bed Diameter | 81 mm (3.2 inches) | Ideal for sewing cylindrical, curved, or small tubular goods with ease. |

| Maximum Stitch Length | 15 mm | Allows for strong, robust seams crucial for heavy-duty applications, preventing unraveling. |

| Max Sewing Speed | 800-1000 RPM (revolutions per minute) | Optimized for control and precision with thick materials, balancing speed with stitch penetration. |

| Needle System | DD x 1 (various sizes available) | Supports robust needles capable of piercing dense, multi-layered materials without breakage. |

| Presser Foot Lift | 20 mm (manual), 30 mm (knee) | Ample clearance for inserting and removing extremely thick bundles of material. |

| Hook Type | Large Barrel Shuttle Hook (Triple Capacity) | Reduces bobbin changes, increasing productivity, especially with heavy threads. |

| Thread Capacity | V346 (Tex 350) to V415 (Tex 400) Heavy Duty Threads | Accommodates the thickest industrial threads for maximum seam strength and durability. |

| Motor | Direct Drive Servo Motor (750W or higher) | Precise speed control, high torque, energy efficiency, and quiet operation. |

Fig. 3: Cylinder bed design facilitates sewing complex shapes.

Application Scenarios and Technical Advantages

The unique capabilities of a long arm sewing machine, particularly models like the GA441-L38, open up a vast array of application possibilities across various demanding industries.

Primary Application Industries:

- Upholstery and Furniture: For crafting large sofa covers, intricate patterns on chairs, and deep-tufted furniture, where maneuvering bulky fabric is essential. This often involves a dedicated long arm upholstery sewing machine.

- Automotive Interiors: Manufacturing car seats, dashboards, door panels, and other interior components that demand precise stitching on thick leather, vinyl, and composite materials.

- Marine and Outdoor Canvas: Producing boat covers, bimini tops, sails, awnings, and tents, which require robust seams to withstand harsh environmental conditions. The long arm facilitates working on expansive panels.

- Leather Goods: Crafting large leather bags, luggage, saddles, harnesses, and specialized leather apparel. The cylinder bed is particularly advantageous for forming and sewing three-dimensional shapes.

- Industrial Filters and Bags: Sewing heavy-duty filter bags for dust collection systems or large industrial bags, where durability and seam integrity are critical.

- Protective Gear and Military Equipment: Assembling heavy-duty vests, tactical bags, slings, and other items from ballistic fabrics, webbing, and thick straps.

Technical Advantages that Drive Performance:

- Superior Material Handling: The expansive throat space eliminates the struggle of compressing and maneuvering large sections of fabric, significantly reducing production time and operator effort.

- Unparalleled Stitch Quality: The synchronized triple feed mechanism ensures consistent, uniform stitches even across varying material thicknesses or when encountering seams and overlaps. This leads to higher aesthetic quality and enhanced structural integrity of the finished product.

- Enhanced Productivity: Fewer material repositioning steps, combined with the large bobbin capacity, mean more continuous sewing and less downtime. This directly translates to increased output and lower labor costs per unit.

- Reduced Material Damage: Precise material feeding prevents stretching, marking, or damage to delicate yet heavy materials, ensuring a perfect finish on expensive components.

- Versatility in Design: The cylinder bed allows for intricate stitching on curved surfaces and closed shapes that would be impossible on a flatbed machine, opening up new design possibilities for product development.

The specific design and robust construction of the GA441-L38 allow manufacturers to undertake projects with confidence, knowing their machinery can handle the most challenging materials and designs while maintaining precision and speed.

Vendor Comparison and Customized Solutions

Choosing the right supplier for a specialized industrial machine like a long arm sewing machine involves more than just comparing price tags. It requires a thorough evaluation of technical capabilities, support infrastructure, and the ability to provide tailored solutions.

Key Factors for Vendor Selection:

- Reputation and Experience: Longevity in the market and a proven track record of delivering reliable machinery.

- Technical Innovation: Commitment to R&D, incorporating the latest technologies for efficiency, precision, and ease of use.

- Quality of Components: Use of high-grade materials and internationally sourced components ensures machine longevity and performance.

- After-Sales Support: Availability of spare parts, technical assistance, and training.

- Customization Capabilities: The ability to modify standard machines or design bespoke solutions for unique production challenges.

Product Comparison: Specialized vs. Standard Heavy-Duty

| Feature | Standard Heavy-Duty Cylinder Bed | Super Long Arm Extra Heavy Duty (GA441-L38) |

|---|---|---|

| Arm Length / Working Space | Typically 250-400 mm (10-16 inches) | 950 mm (37.4 inches) |

| Material Thickness Capacity | Up to 10-12 mm compressed | Up to 20-25 mm compressed |

| Feed Mechanism | Compound feed (walking foot + bottom feed) | Triple Feed (Walking Foot + Needle Feed + Bottom Feed) |

| Hook Type & Bobbin Size | Large Capacity Rotary Hook | Large Barrel Shuttle Hook (Triple Capacity) |

| Typical Applications | Smaller leather goods, standard upholstery, tarps | Automotive interiors, marine canvas, oversized upholstery, heavy webbing, military equipment |

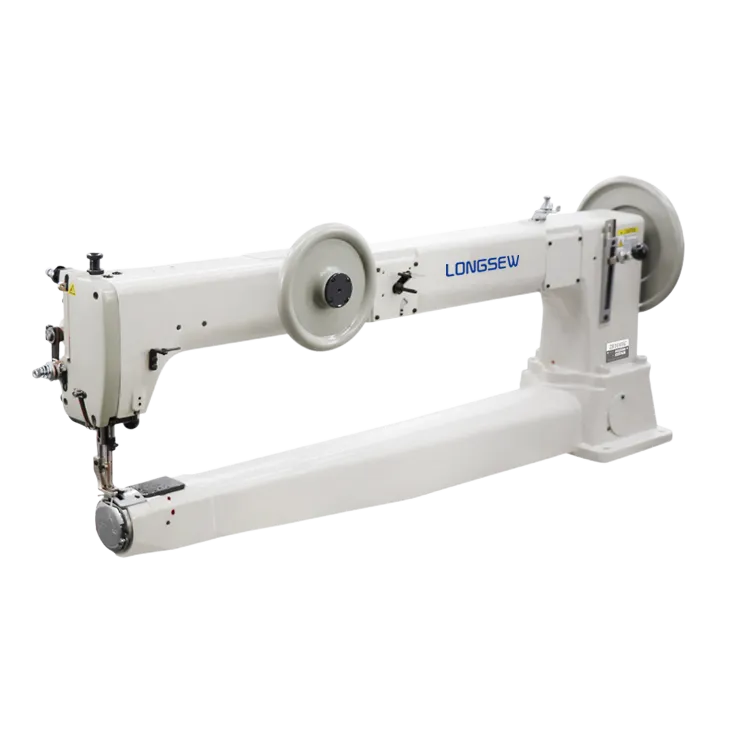

Customized Solutions: Tailoring the Arm Sewing Machine to Your Needs

For highly specialized production lines, off-the-shelf solutions may not suffice. Leading manufacturers offer comprehensive customization services, allowing clients to configure an arm sewing machine that perfectly aligns with their operational requirements. This includes:

- Extended Arm Lengths: Beyond standard long arms, bespoke arm lengths can be engineered for exceptionally large projects.

- Specialized Feed Systems: Modifications to the walking foot, needle feed, or bottom feed for unique material characteristics (e.g., extremely slippery, highly abrasive, or unusually structured textiles).

- Automated Material Handling: Integration with automated guided vehicles (AGVs), material clamping systems, or robotic work cells for seamless production flows.

- Custom Tooling: Development of specific presser feet, binders, or guides to facilitate complex stitching operations or specific product designs.

- Software Integration: Custom programming for intricate stitch patterns, data logging, and integration with existing ERP/MES systems.

Fig. 4: Customization options for specialized production.

Real-world Application Case Studies and Customer Experience

The practical impact of a robust long arm sewing machine is best illustrated through real-world applications. These examples demonstrate how businesses leverage advanced sewing technology to overcome production challenges and achieve superior results.

Case Study 1: Luxury Automotive Upholstery Manufacturer

A leading manufacturer of bespoke automotive interiors faced significant challenges in producing seamless, high-quality seat covers for luxury vehicles. The large, intricate leather panels and multi-layered foam components were difficult to maneuver on standard industrial machines, leading to inconsistent stitch lines and operator fatigue.

- Challenge: Handling large, complex leather sections without creasing or shifting, maintaining consistent stitch quality over long seams and tight curves.

- Solution: Implementation of multiple GA441-L38 Super Long Arm Extra Heavy Duty Cylinder Bed Sewing Machines. The extensive arm length facilitated easy movement of full seat panels, while the cylinder bed was crucial for precise stitching on bolster contours. The triple feed system ensured perfectly aligned layers, even with thick foam backing.

- Outcome: A 30% increase in production efficiency due to reduced material repositioning, a 15% reduction in material waste from improved stitch consistency, and a marked improvement in overall product finish, enhancing brand reputation. Customer feedback highlighted the "flawless seam quality" enabled by the machines.

Case Study 2: Industrial Tarpaulin and Tent Manufacturer

An established producer of large-scale industrial tarpaulins and event tents struggled with the sheer size and weight of PVC-coated fabrics and heavy-duty webbing. Stitching long, continuous seams on these materials was time-consuming and often required multiple operators.

- Challenge: Sewing extremely long and wide panels of heavy, rigid materials with minimal stretch, ensuring water-tight seams and high structural integrity.

- Solution: Adoption of the GA441-L38 machines. The 950mm arm length allowed for continuous stitching along the entire length of even the largest tarpaulin sections. The robust construction and powerful motor easily handled the thickest threads and multiple layers of PVC-coated fabric, while the large barrel shuttle hook reduced bobbin changes significantly.

- Outcome: Production throughput improved by 40%, and the quality of the seams was superior, passing rigorous waterproofing tests consistently. The operator noted that the stability provided by the long arm and the powerful feeding mechanism made the challenging work "much more manageable and precise," reinforcing the value of a specialized arm in sewing machine.

Fig. 5: Industrial production utilizing long arm technology for large textiles.

Trustworthiness, Support, and FAQ

Establishing trust and providing comprehensive support are cornerstones of B2B relationships, especially for critical industrial equipment. Manufacturers of high-end machinery like the GA441-L38 commit to robust certification, transparent policies, and responsive customer service.

Authoritative Certifications & Partnerships:

- ISO 9001:2015 Certified: Demonstrates a commitment to quality management systems in design, development, production, and service.

- CE Marking: Confirms compliance with European Union health, safety, and environmental protection standards.

- Strategic Partnerships: Collaborations with global component suppliers (e.g., servo motor manufacturers, needle companies) ensure access to the best available technologies and spare parts.

- Years of Service: Reputable manufacturers often boast decades of experience in the industry, underscoring their expertise and reliability.

Frequently Asked Questions (FAQ):

A: The GA441-L38 is designed for extremely thick and heavy materials, including multi-layered leather, heavy canvas, PVC, industrial webbing, ballistic fabrics, and dense synthetic composites. Its triple feed and high presser foot lift ensure smooth handling.

Q2: What is the typical lead time for an order of a Super Long Arm Extra Heavy Duty machine?A: Standard models typically have a lead time of 4-6 weeks from order confirmation to shipment, depending on current production schedules and customization requirements. For highly customized solutions, lead times may extend to 8-12 weeks, which will be communicated clearly during the quotation process.

Q3: What kind of warranty and after-sales support is provided?A: We offer a comprehensive 12-month warranty on all mechanical and electrical components, excluding consumable parts (needles, bobbins, etc.). Our after-sales support includes remote technical assistance via phone/video, online troubleshooting guides, and a global network of authorized service partners for on-site support and spare parts supply. Training programs for operators and maintenance staff are also available.

Lead Time & Fulfillment Details:

- Order Processing: Orders are processed within 2-3 business days upon receipt of a confirmed purchase order and initial deposit.

- Manufacturing & Testing: Each machine undergoes rigorous manufacturing, assembly, and testing phases. Real-time updates can be provided upon request.

- Shipping & Logistics: We partner with reputable international logistics providers to ensure safe and timely delivery worldwide. Clients are provided with tracking information and assistance with customs documentation.

Warranty Commitments:

- Standard Warranty: 1-year coverage from the date of installation or 15 months from shipment (whichever comes first) against manufacturing defects.

- Extended Warranty: Options for extended warranty periods are available upon request and can be tailored to specific operational needs.

Customer Support Information:

Our dedicated support team is available to assist with technical inquiries, spare part orders, and operational guidance.

- Technical Support Hotline: Available during business hours for immediate assistance.

- Email Support: Responsive email channels for detailed inquiries and documentation.

- Online Resource Portal: Access to manuals, video tutorials, and troubleshooting guides.

- Spare Parts Availability: A comprehensive inventory of genuine spare parts ensures minimal downtime.

The industrial long arm sewing machine, epitomized by models like the Super Long Arm Extra Heavy Duty Cylinder Bed Sewing Machine For Big & Thick Material Products GA441-L38, represents a crucial investment for businesses operating in demanding material fabrication sectors. Its advanced engineering, robust construction, and specialized capabilities enable unparalleled efficiency and quality in handling complex, large-scale projects. By embracing these sophisticated tools, manufacturers can enhance productivity, maintain stringent quality standards, and stay competitive in a rapidly evolving global market.

References:

- ISO (International Organization for Standardization). (2015). ISO 9001:2015 Quality management systems – Requirements. Retrieved from www.iso.org

- ANSI (American National Standards Institute). (2018). ANSI/ASME B11.1-2018 Safety Requirements for Mechanical Power Presses. Retrieved from www.ansi.org

- National Institute for Occupational Safety and Health (NIOSH). (2017). Ergonomic Guidelines for Sewing Machine Operators. Retrieved from www.cdc.gov/niosh

- Textile World Magazine. (2023). Innovations in Industrial Sewing Technology for Heavy Fabrics. Retrieved from www.textileworld.com

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025