leather sewing machine parts

The Essentials of Leather Sewing Machine Parts

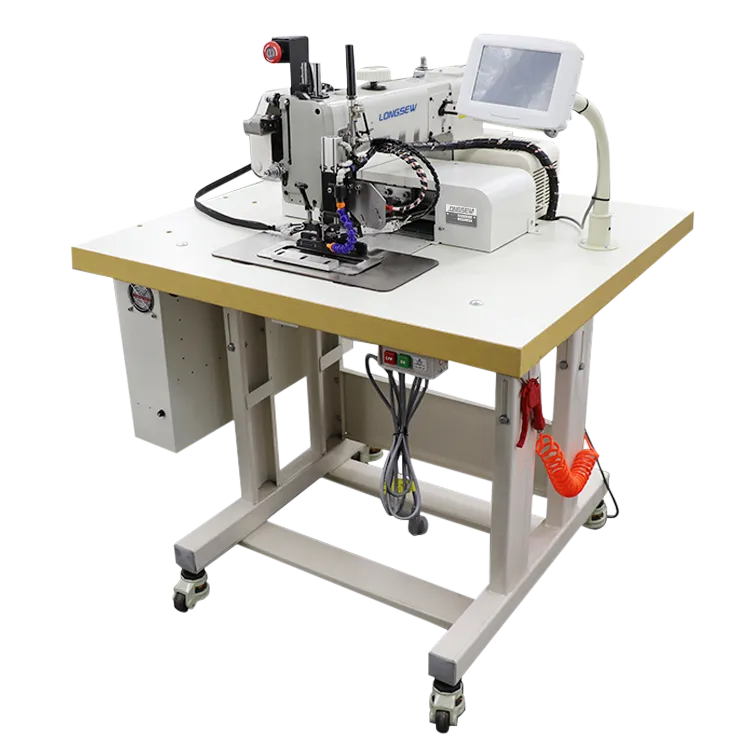

When it comes to crafting leather goods, having the right tools is essential, and a dependable sewing machine plays a key role in the process. Leather sewing machines are specifically designed to handle the unique challenges presented by sewing leather, including its thickness, toughness, and tendency to slip. Understanding the various parts of a leather sewing machine enables leather artisans to optimize their work, ensuring that each project is executed with precision and finesse.

1. Machine Body and Frame

The frame of a leather sewing machine is the foundation that provides stability and strength during the sewing process. Typically made from heavy-duty metal, this part is crucial for absorbing vibrations that occur when sewing through multiple layers of thick leather. A robust frame ensures that the machine remains steady, allowing for more accurate stitching and reducing the risk of needle breakage.

The needle is a vital component of any sewing machine, but when it comes to leather, it requires special consideration. Leather needles have a wedge-shaped point designed to puncture through tough materials, minimizing the risk of damaging the leather. The needle plate, located beneath the needle, provides a smooth bed for the leather to glide over while sewing. It often features a throat plate with markings to help guide straight stitching, making it easier for crafters to achieve a professional finish.

3. Feed Dogs and Presser Foot

Feed dogs are small, serrated teeth located on the sewing machine’s surface that grip the fabric and move it through the machine as you sew. In the context of leather, it is essential for the feed dogs to provide enough grip without damaging the delicate surface of the leather. Adjustable presser feet are equally important; they can be customized to provide more or less pressure depending on the thickness of the leather being used. Some machines come with specialty feet designed expressly for leatherwork, such as roller feet or walking feet, which help facilitate smooth feeding of the material.

leather sewing machine parts

4. Tension Control

Proper tension is critical in achieving the desired stitch quality, especially with leather. Tension control mechanisms allow the user to adjust the upper and lower thread tension, which can significantly affect the finished look of the seams. Leather sewing requires a balance in tension to prevent puckering or excessive tightness, so understanding how to manipulate the tension settings is essential for any leatherworker.

5. Bobbin and Bobbin Case

The bobbin is a small spool that holds the lower thread necessary for forming stitches. Leather sewing machines typically use a heavier, sturdier bobbin to accommodate the demands of thicker threads that are commonly used in leather projects. The bobbin case, which houses the bobbin, should allow for easy removal and replacement, ensuring that the sewing process remains uninterrupted.

6. Motor

The motor is the powerhouse of the sewing machine, influencing speed and efficiency. Leather sewing machines often come equipped with stronger motors to handle the extra workload associated with heavier materials. Some modern machines even feature programmable motors that allow users to set specific speeds, providing even more control during delicate sections of sewing.

Conclusion

Understanding the various parts of a leather sewing machine is crucial for anyone serious about leather crafting. By familiarizing oneself with these components, artisans can enhance their skills and improve the quality of their work. Whether you're creating handbags, wallets, or belts, knowing how to effectively utilize machine parts will ultimately contribute to the durability and aesthetic appeal of your leather projects. As technology advances, the world of leather sewing machines continues to evolve, offering even more capabilities to help bring creative visions to life. By investing in quality machine parts and maintaining them properly, leatherworkers can enjoy a seamless sewing experience that yields professional results.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025