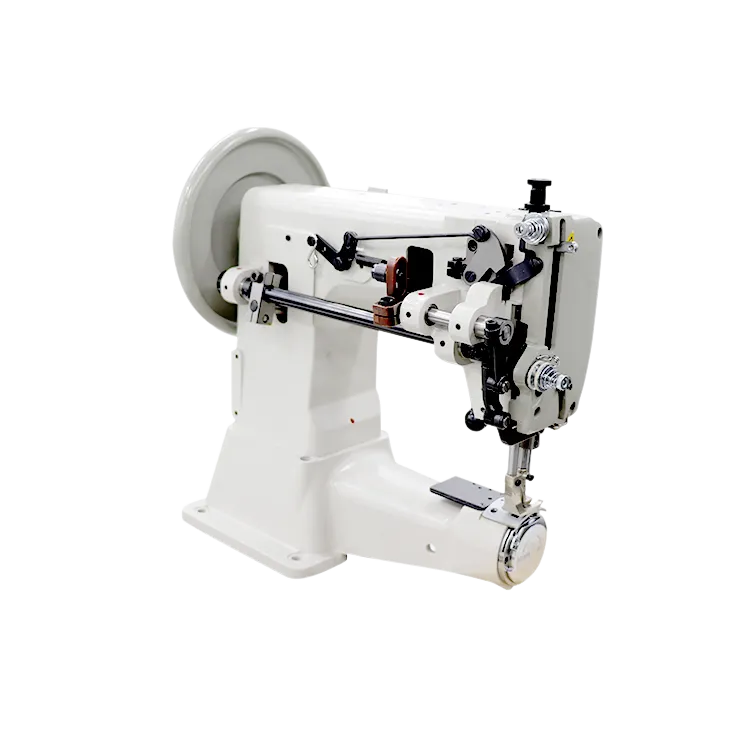

leather upholstery machine

The Evolution and Importance of Leather Upholstery Machines

Leather upholstery machines play a crucial role in the upholstery industry, transforming raw leather into beautifully crafted furniture, automotive interiors, and various decorative items. With the growing demand for luxury and customized leather goods, the evolution of these machines has been vital for manufacturers aiming to meet consumer expectations while enhancing productivity and efficiency.

Historically, the art of leather upholstery was a manual process, relying heavily on skilled artisans who would meticulously sew and cut leather by hand. This labor-intensive method, though rich in craftsmanship, was time-consuming and often produced inconsistent results. As the demand for leather products increased, especially in the automotive and furniture sectors, the need for more efficient manufacturing processes became evident. This demand spurred the development of specialized machines designed to automate key aspects of leather upholstery, allowing for greater precision and speed.

Today, leather upholstery machines are equipped with sophisticated technologies, including computerized sewing systems, automated cutting tools, and advanced stitching techniques. These innovations have revolutionized the industry, allowing manufacturers to produce consistent, high-quality upholstery that meets the standards of modern consumers. For instance, computerized cutting machines can accurately cut multiple layers of leather simultaneously, ensuring that every piece is uniform and reduces material waste.

leather upholstery machine

In addition to efficiency, modern leather upholstery machines offer versatility

. Manufacturers can create a vast array of products, from high-end furniture to car interiors, all while accommodating different types of leather and designs. The ability to quickly switch between various tasks enables companies to cater to niche markets and consumer preferences, such as custom designs or unique leather finishes.Furthermore, the integration of environmental considerations into the manufacturing process cannot be overlooked. As consumers become increasingly conscientious about sustainability, manufacturers are utilizing leather upholstery machines that are designed with eco-friendly practices in mind. This includes machines that minimize waste, utilize water-based adhesives, and implement recycling processes for scrap materials. By adopting such practices, businesses not only meet regulatory standards but also enhance their brand reputation among environmentally aware consumers.

The advancements in leather upholstery machine technology are also reflected in the level of worker training and skill development required. While these machines automate many processes, skilled operators are essential for overseeing the production and ensuring that quality standards are met. Thus, the industry has seen a shift toward emphasizing technical training and education, equipping workers with the skills needed to operate complex machinery and adapt to new technologies.

In conclusion, leather upholstery machines have significantly changed the landscape of the upholstery industry. Their evolution has allowed for greater efficiency, versatility, and sustainability, aligning with the modern consumer's demands for quality and customization. As technology continues to advance, we can expect further innovations that will enhance the capabilities of leather upholstery machines, ensuring that they remain an integral part of the manufacturing process for years to come. This ongoing development not only benefits manufacturers but also the consumers who appreciate the fine quality and artistry of leather upholstery in their everyday lives.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025