sewing techniques for creating a durable jumbo belt design and production tips

The Versatile World of Jumbo Belt Sewing

Jumbo belts are more than just fashionable accessories; they embody a unique blend of practicality and style. In a world where fashion is often fleeting, jumbo belts have garnered attention for their size and functionality. However, the real artistry lies in the art of sewing these belts, a process that transforms raw materials into a statement piece.

The Importance of Material Selection

When it comes to jumbo belt sewing, the choice of material is crucial. Different fabrics lend themselves to different styles and functionalities. Common materials used for these belts include leather, canvas, and synthetic options like nylon. Each material has its own advantages leather offers durability and a classic look, canvas is lightweight and versatile, while synthetic fabrics are often waterproof and easy to clean. The right material not only enhances the appearance of the belt but also affects its durability and comfort.

Design and Pattern Making

Before any sewing begins, a design plan is essential. Creating a design for a jumbo belt involves considering its purpose is it meant to be a statement piece, or is it intended for outdoor activities? Designers often sketch their ideas, paying attention to the width, buckle style, and overall aesthetic. Pattern making follows, where templates are created to guide the cutting and sewing processes. This stage is vital because the precision of patterns directly influences the final product’s quality.

Sewing Techniques

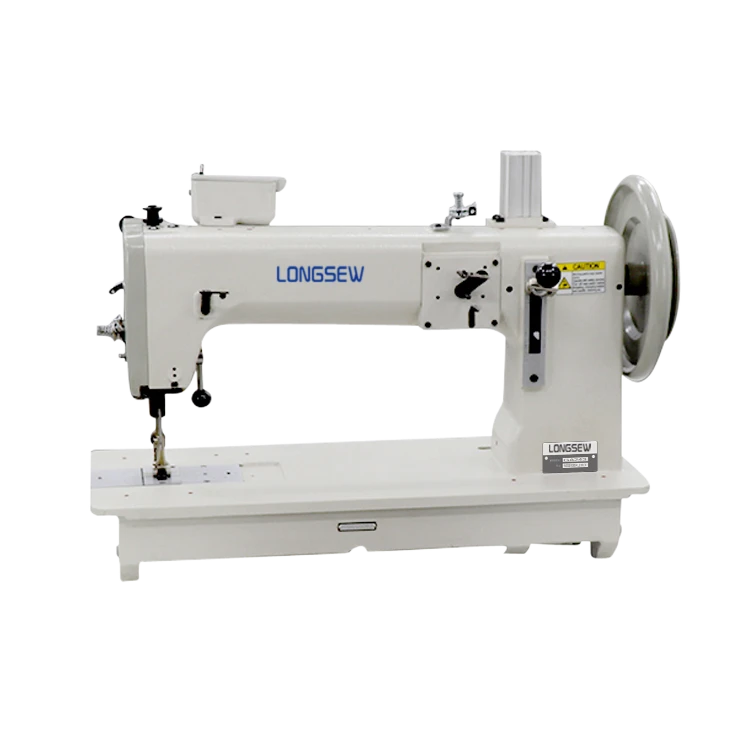

Jumbo belts typically require specific sewing techniques due to their size and the materials used. Heavy-duty sewing machines are often employed to handle thicker fabrics like leather or multiple layers of canvas. The stitching method is also important; for example, using a straight stitch or a zigzag stitch can impact the belt's flexibility and strength. Reinforcing areas that undergo stress, such as where the buckle attaches, is crucial to ensure longevity. Some designers also incorporate decorative stitching as part of the belt’s design, adding a personalized touch.

jumbo belt sew

Assembly and Finishing Touches

Once the pieces are cut and sewn together, assembly begins. This involves attaching the buckle, loops, and any additional elements like decorative patches or studs. Attention to detail is paramount at this stage. A well-placed stitch can mean the difference between a standard belt and a show-stopping accessory. After assembly, finishing touches such as trimming excess threads and conditioning leather (if used) can elevate the overall appearance and functionality.

Customization and Personalization

One of the growing trends in jumbo belt sewing is customization. Consumers are increasingly looking for unique items that reflect their personalities. This has led to a rise in the popularity of bespoke belts, where individuals can choose colors, materials, and even add personal inscriptions. Customization not only enhances the uniqueness of the product but also fosters a deeper connection between the wearer and their accessory.

Sustainability in Manufacturing

As with many aspects of fashion today, sustainability has become a focus in jumbo belt sewing. Sustainable practices, such as using eco-friendly materials, repurposing fabric scraps, and ethical labor practices, are on the rise. Many brands are now dedicated to producing belts that not only look good but are made responsibly. Consumers are becoming more conscious of their purchasing choices, and companies that prioritize sustainability often stand out in a crowded market.

Conclusion

The art of sewing jumbo belts is an intricate process that encapsulates creativity, functionality, and sustainability. From material selection to the final finishing touches, every step is essential in crafting a product that not only meets practical needs but also serves as an expression of personal style. Whether one opts for a bold, oversized statement piece or a more understated option, jumbo belts are here to stay, reflecting the ever-evolving landscape of fashion.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025