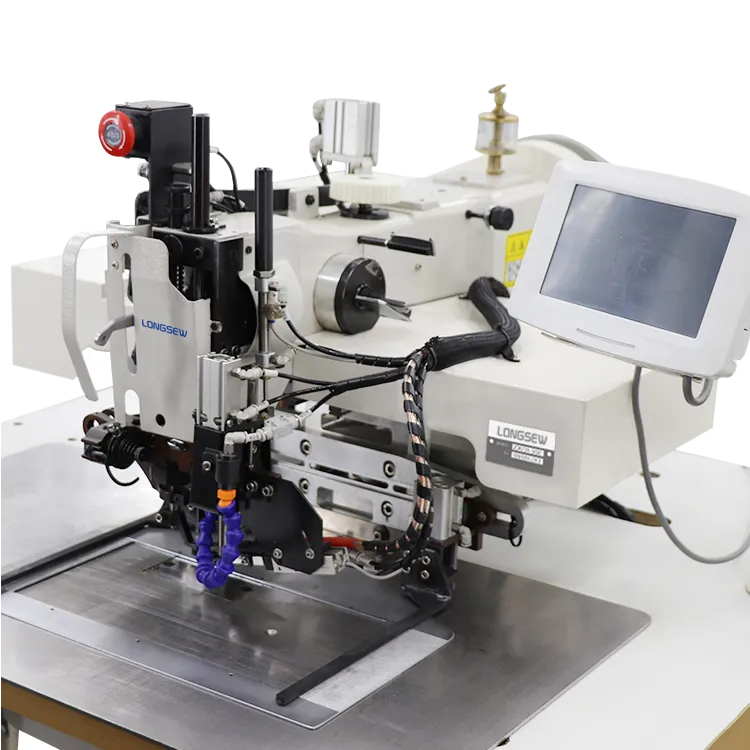

jumbo bag loopsew

Jumbo Bag Loop Sew An Efficient Solution for Bulk Packaging

In the realm of packaging solutions, jumbo bags, also known as bulk bags or FIBC (Flexible Intermediate Bulk Container) bags, are a cornerstone for industries that deal with the storage and transportation of bulk materials. One of the significant components involved in the construction of these bags is the loop sew technique, which is essential for ensuring structural integrity and ease of handling. This article delves into the world of jumbo bag loop sew, exploring its benefits, applications, and the underlying technology that makes it a favored choice in various sectors.

The Importance of Loop Sew in Jumbo Bags

Loop sewing is an essential process in the production of jumbo bags, particularly for the integrated loops used for lifting and handling. The loops are typically sewn directly into the fabric of the bag, creating a secure attachment point that can endure heavy loads. The sewing process involves utilizing strong, durable threads that can resist wear and deterioration, maintaining the bag's usability even under challenging conditions.

The loop sew design not only enhances the load-bearing capacity of these bags, but it also facilitates easier handling. Users can hook these padded loops onto forklifts or other lifting equipment for efficient loading and unloading. This design feature minimizes the risk of accidents and injuries associated with manual bag handling, making operations smoother and safer.

Benefits of Jumbo Bags with Loop Sew

1. Robust Construction The loop sewing technique reinforces the structural integrity of jumbo bags. This durability is vital when transporting materials such as sand, gravel, agricultural products, chemicals, or food grains that require secure containment.

2. Versatility Jumbo bags equipped with loop sew can be customized for various applications. Manufacturers offer bags in different sizes, materials, and weight capacities, allowing industries to choose bags that suit their specific needs, from lightweight agricultural products to heavy construction materials.

3. Cost-Effectiveness When compared to rigid containers or smaller packaging options, jumbo bags offer a more cost-effective solution for transporting bulk goods. They reduce shipping costs by maximizing storage space and minimizing waste.

4. Sustainability Many jumbo bags are manufactured from recyclable polypropylene, which is an environmentally friendly option. The bags can be reused multiple times, and at the end of their life cycle, they can be recycled, thereby reducing waste in landfills.

jumbo bag loopsew

Applications of Jumbo Bags

Jumbo bags with loop sew are widely used across several industries

- Agriculture Farmers and producers utilize these bags to store and transport fertilizers, grains, seeds, and various agricultural products. The looped handles make it easy to move these heavy bags from place to place, particularly in rural settings.

- Construction In the construction industry, jumbo bags are used for transporting sand, stone, and other bulk materials. Loop sew bags can hold significant weights, making them ideal for lifting heavy aggregates.

- Chemicals The chemical industry often requires specialized bags for safe handling and transportation of chemical products. Loop-sewn jumbo bags can be designed with specific properties to ensure they are leak-proof and resistant to various chemicals.

- Food Industry In food processing, jumbo bags are used for grains, sugar, flour, and other bulk edible products. The food-safe materials and careful construction ensure that these bags do not contaminate the contents.

The Future of Jumbo Bag Loop Sew

As industries evolve and demand for efficient bulk packaging solutions continues, the technology surrounding jumbo bag loop sew is expected to advance as well. Innovations in materials science could lead to even stronger and lighter fabrics, enhancing the functionality of these bags. Additionally, the incorporation of smart technologies, such as RFID tags or QR codes, may offer real-time tracking and inventory management for businesses that rely heavily on bulk materials.

In conclusion, the loop sew technique in the construction of jumbo bags is a critical aspect that contributes to their durability and efficiency. With a wide range of applications across various industries, these bags provide a reliable solution for bulk packaging needs. As industries continue to streamline operations and seek sustainable practices, the importance of jumbo bags and their loop sew features will only grow, cementing their place as indispensable tools in bulk material handling.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025