Fev . 06, 2025 05:51

Back to list

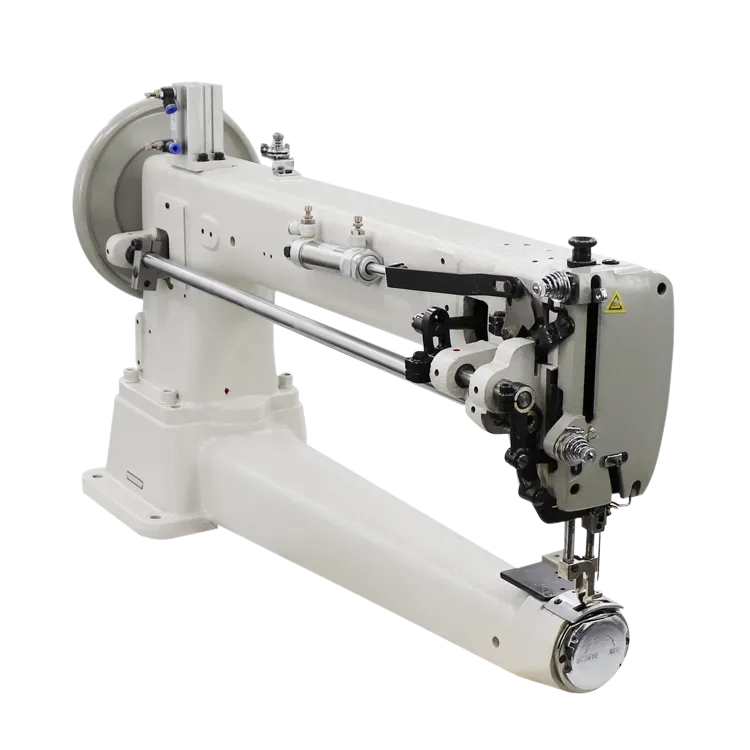

Heavy Duty Computerized Auto Pattern Sewing Machine For Safety Rope or Safety Belt LS273-2010H / LS273-2010S

The world of automotive upholstery is a realm where precision and durability are paramount. Every stitch not only holds fabric together but also combines both aesthetics and functionality to withstand the rigors of automotive usage. The industrial sewing machine for auto upholstery stands as the cornerstone of achieving such craftsmanship. This meticulously engineered machine is not just a tool but an essential companion for any upholstery professional aiming for excellence.

An overlooked yet crucial aspect is the compatibility of needles and threads used with the machine. Heavy-duty upholstery demands needles that match the strength and type of fabric, with common sizes ranging from 18 to 22. Similarly, thread selection is critical, where nylon or polyester options provide the best resilience. It's important for professionals to understand the intricacies of thread tension and its impact on stitch quality. Misaligned tension can lead to loops or breaks in the stitch, tarnishing the upholstery work. Investing in an industrial sewing machine specific to auto upholstery not only improves production efficiency but also elevates the quality of the finished product. The investment often translates into reduced time spent per project and allows for tackling a wider range of materials and designs. In the digital world where information on these machines is widespread, distinguishing between marketing myths and genuine performance insights is critical. Many professionals turn to communities and forums, sharing real-time experiences, failures, and successes with their machines. This experience-based learning often provides a practical backdrop beyond manufacturer specifications, offering first-hand solutions to potential challenges. In conclusion, an industrial sewing machine tailored for auto upholstery is essential not just for its power and durability, but also for its ability to deliver precision and aesthetics in each stitch. The combination of innovative features, consistent practice, regular maintenance, and the commitment to understanding one's machine transforms upholstery work, allowing a professional to not only meet but exceed the demanding standards of the automotive world.

An overlooked yet crucial aspect is the compatibility of needles and threads used with the machine. Heavy-duty upholstery demands needles that match the strength and type of fabric, with common sizes ranging from 18 to 22. Similarly, thread selection is critical, where nylon or polyester options provide the best resilience. It's important for professionals to understand the intricacies of thread tension and its impact on stitch quality. Misaligned tension can lead to loops or breaks in the stitch, tarnishing the upholstery work. Investing in an industrial sewing machine specific to auto upholstery not only improves production efficiency but also elevates the quality of the finished product. The investment often translates into reduced time spent per project and allows for tackling a wider range of materials and designs. In the digital world where information on these machines is widespread, distinguishing between marketing myths and genuine performance insights is critical. Many professionals turn to communities and forums, sharing real-time experiences, failures, and successes with their machines. This experience-based learning often provides a practical backdrop beyond manufacturer specifications, offering first-hand solutions to potential challenges. In conclusion, an industrial sewing machine tailored for auto upholstery is essential not just for its power and durability, but also for its ability to deliver precision and aesthetics in each stitch. The combination of innovative features, consistent practice, regular maintenance, and the commitment to understanding one's machine transforms upholstery work, allowing a professional to not only meet but exceed the demanding standards of the automotive world.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025