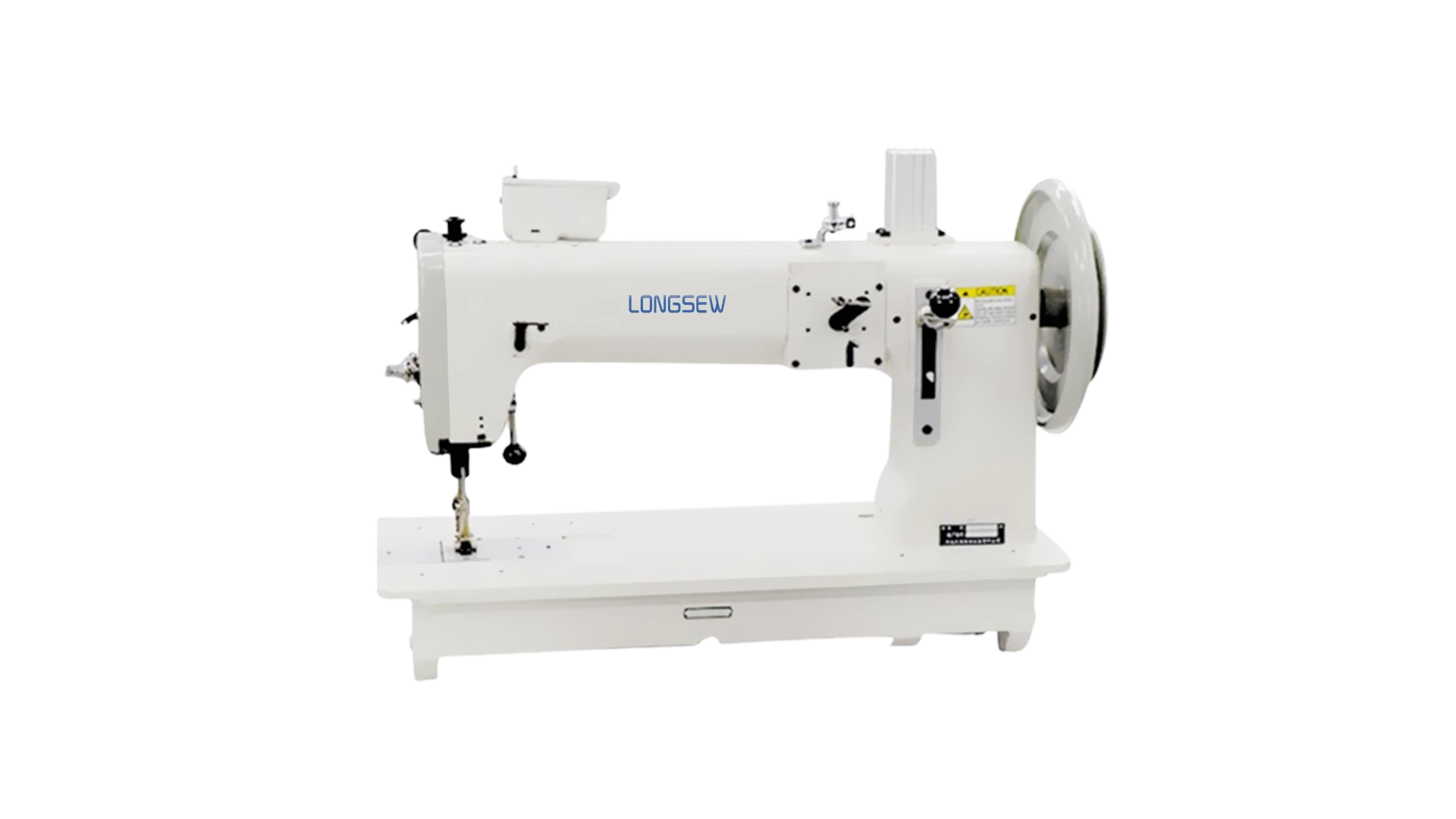

high speed lockstitch sewing machine

High-Speed Lockstitch Sewing Machine Revolutionizing the Textile Industry

The high-speed lockstitch sewing machine has become a cornerstone of modern garment manufacturing, transforming the way textiles are produced and enhancing productivity across the industry. This advanced machinery is renowned for its efficiency, precision, and versatility, making it a preferred choice for manufacturers worldwide.

Understanding the Lockstitch Mechanism

At the heart of the high-speed lockstitch sewing machine is the lockstitch mechanism. This system utilizes two threads—one from the needle and the other from a bobbin—to create a secure stitch. When the needle penetrates the fabric, it pulls the upper thread through, which then intertwines with the lower thread from the bobbin, forming a locked stitch on the underside of the fabric. This unique construction ensures that the stitches are strong and can withstand considerable tension, making it ideal for heavy fabrics and intricate designs.

Features and Benefits

1. Speed and Efficiency As the name suggests, high-speed lockstitch sewing machines operate at impressive speeds, often exceeding 5000 stitches per minute. This capability allows manufacturers to complete large volumes of work in a short period, significantly reducing production timelines.

2. Precision and Consistency These machines are designed to deliver consistent results, making them perfect for mass production environments. The lockstitch mechanism minimizes the risk of fabric puckering, thereby ensuring uniform stitching quality across all pieces of a garment.

3. Versatility High-speed lockstitch machines can handle a wide range of fabrics, from lightweight materials like silk to heavier options like denim. This versatility allows manufacturers to produce diverse clothing lines without the need for multiple types of sewing machines.

4. User-Friendly Design Modern machines often come equipped with electronic controls, which streamline operations and enhance the user experience. Features such as automatic thread cutting, programmable stitching patterns, and easy-to-navigate interfaces make these machines accessible even to those with minimal sewing experience.

high speed lockstitch sewing machine

5. Reduced Labor Costs By increasing the speed of production and decreasing the likelihood of errors, high-speed lockstitch sewing machines contribute to lower labor costs. Workers can focus on more complex tasks that require human skill while the machines handle repetitive sewing tasks efficiently.

Advances in Technology

Technology has played a significant role in the evolution of high-speed lockstitch sewing machines. Recent innovations have introduced computerized systems that allow for greater customization and control over the sewing process. For instance, operators can now program specific stitch patterns, adjust tension settings on the fly, and monitor machine performance in real time.

Additionally, the integration of robotics and automation has enabled manufacturers to further enhance their production capabilities. Automated feeding systems and fabric handling mechanisms work harmoniously with high-speed lockstitch machines, minimizing manual intervention and maximizing efficiency.

Challenges and Considerations

Despite their numerous benefits, high-speed lockstitch sewing machines are not without challenges. One notable concern is the need for regular maintenance to ensure optimal performance. Over time, machines can experience wear and tear, leading to decreased stitching quality. Manufacturers must invest in routine servicing and operator training to mitigate these issues.

Moreover, as with any advanced machinery, there is a learning curve associated with operating high-speed lockstitch sewing machines. Adequate training is essential to fully leverage the machine's capabilities and to maintain safety in the workplace.

Conclusion

In conclusion, the high-speed lockstitch sewing machine has revolutionized the textile industry by enhancing productivity, precision, and versatility. As manufacturers continue to adopt these advanced machines, the future of garment production looks promising. With ongoing technological advancements, the potential for improvements in efficiency and quality is limitless, paving the way for a new era in textile manufacturing. Whether in a small workshop or a large factory, these machines are indispensable tools that drive innovation and excellence in the fashion industry.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025