Jan . 26, 2025 05:03

Back to list

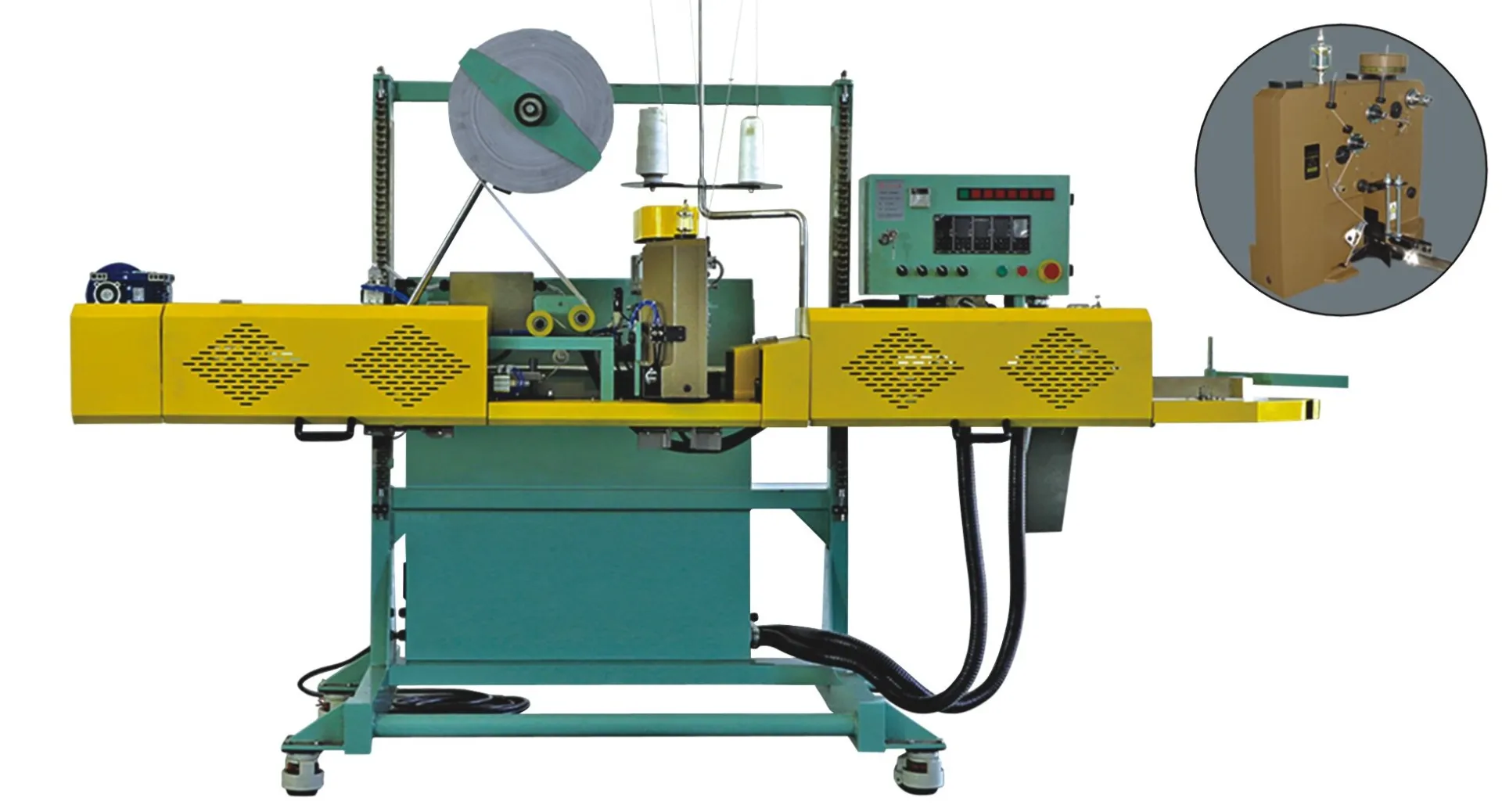

heavy duty industrial sewing machine

Choosing the right heavy duty sewing machine industrial model can radically transform your manufacturing capabilities, offering robust performance that withstands intensive use while delivering precision and reliability. These machines are not mere tools; they are the backbone of many textile industries, ensuring that businesses can thrive by meeting demands efficiently. Understanding the full range of features, as well as their appropriate applications, is essential for any industry professional tasked with selecting the perfect sewing solution.

A crucial consideration is the specific features that align with production requirements. Some machines are equipped with programmable digital controls allowing for customized stitching patterns, automatic thread cutters, and speed regulators. Others offer specialty feet and attachments designed for unique tasks, such as walking foot mechanisms for quilting or piping feet for decorative applications. Selecting a machine with the appropriate features enhances operational efficiency and expands creative possibilities. Safety is another critical element when working with heavy duty industrial sewing equipment. Machines should be equipped with safety measures, such as emergency stop buttons, needle guards, and controlled access to moving parts to protect operators from injury. Regular training and adherence to best safety practices further ensure a secure working environment. The investment in a heavy-duty industrial sewing machine is substantial, but the return in terms of productivity, product quality, and business growth potential can be significant. Financing options and cost analyses should be considered, alongside the machine's long-term benefits to the production line. Evaluating total cost of ownership versus productivity gains is essential for sound fiscal decision-making. In conclusion, an industrial heavy duty sewing machine is more than just an asset in the textile and manufacturing industries; it is a strategic investment that enhances capabilities, ensures product consistency, and supports growth. With a focus on reliability, efficiency, and productivity, professionals equipped with quality machinery and the right expertise can respond quickly to market demands, achieve operational excellence, and sustain competitiveness in a dynamic marketplace. Proper selection, coupled with regular maintenance and operator training, ensures these machines remain valuable, long-term contributors to industrial success.

A crucial consideration is the specific features that align with production requirements. Some machines are equipped with programmable digital controls allowing for customized stitching patterns, automatic thread cutters, and speed regulators. Others offer specialty feet and attachments designed for unique tasks, such as walking foot mechanisms for quilting or piping feet for decorative applications. Selecting a machine with the appropriate features enhances operational efficiency and expands creative possibilities. Safety is another critical element when working with heavy duty industrial sewing equipment. Machines should be equipped with safety measures, such as emergency stop buttons, needle guards, and controlled access to moving parts to protect operators from injury. Regular training and adherence to best safety practices further ensure a secure working environment. The investment in a heavy-duty industrial sewing machine is substantial, but the return in terms of productivity, product quality, and business growth potential can be significant. Financing options and cost analyses should be considered, alongside the machine's long-term benefits to the production line. Evaluating total cost of ownership versus productivity gains is essential for sound fiscal decision-making. In conclusion, an industrial heavy duty sewing machine is more than just an asset in the textile and manufacturing industries; it is a strategic investment that enhances capabilities, ensures product consistency, and supports growth. With a focus on reliability, efficiency, and productivity, professionals equipped with quality machinery and the right expertise can respond quickly to market demands, achieve operational excellence, and sustain competitiveness in a dynamic marketplace. Proper selection, coupled with regular maintenance and operator training, ensures these machines remain valuable, long-term contributors to industrial success.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025