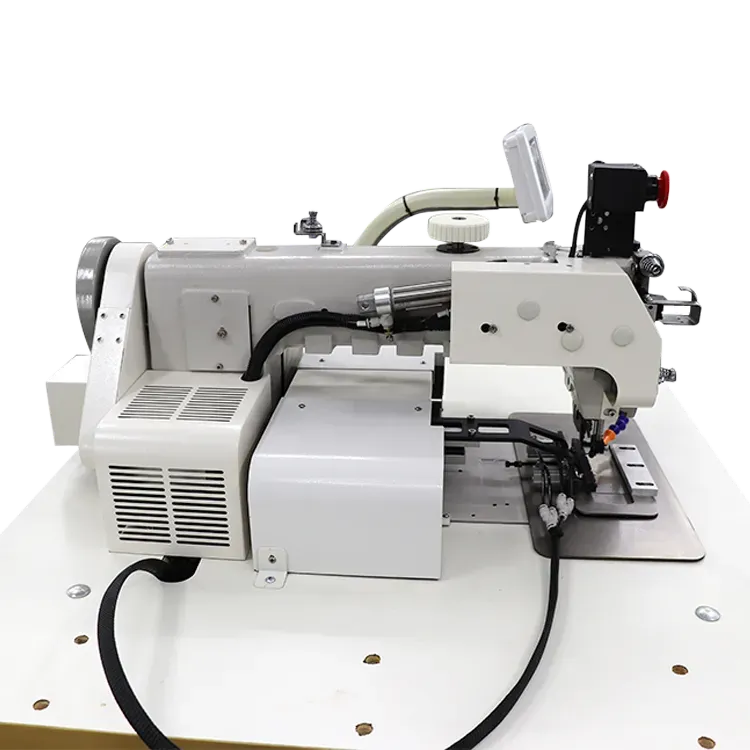

fibc sealing sewing machine

The Importance of FIBC Sealing Sewing Machines in Modern Manufacturing

In the landscape of modern manufacturing, particularly in the packaging sector, FIBC (Flexible Intermediate Bulk Container) bags play a crucial role. These versatile bags are designed to store and transport bulk materials such as grains, chemicals, and construction materials. The integrity of FIBC bags is essential, and this is where FIBC sealing sewing machines come into play.

FIBC bags are usually made from woven polypropylene, a material that provides strength and durability. However, the quality of the seams is critical to ensuring that the bags can withstand the rigors of handling and transport. This is achieved through the use of specialized sealing sewing machines that are specifically designed for the unique requirements of FIBC production.

How FIBC Sealing Sewing Machines Work

FIBC sealing sewing machines are engineered to create strong, tight seams that prevent rupture or leakage of contents. These machines employ advanced technology to ensure that the stitching is consistent and durable. One of the common methods used in these machines is the double-stitched seam technique, which significantly enhances the bag's strength.

Moreover, FIBC sewing machines are equipped with various features that contribute to their efficiency and effectiveness. For example, some models come with programmable controls that allow operators to set specific stitch patterns and speeds, ensuring uniformity across batches. Additionally, the use of high-quality thread that can withstand various environmental conditions further enhances the reliability of the sealed bags.

Key Benefits of FIBC Sealing Sewing Machines

fibc sealing sewing machine

2. Quality Assurance With high precision in stitching and sealing, manufacturers can ensure that their products meet stringent quality standards, reducing the risk of product loss due to bag failure.

3. Increased Productivity Modern FIBC sealing sewing machines are designed for high-speed operation, enabling manufacturers to produce a larger quantity of bags in a shorter amount of time.

4. Customization Many machines allow for customization in terms of bag size, stitch pattern, and even the incorporation of additional features such as top closures or discharge spouts.

5. Cost Efficiency By minimizing material waste and reducing the likelihood of product damage during transit, these machines contribute to a more cost-effective manufacturing process.

Conclusion

In summary, FIBC sealing sewing machines are indispensable in the manufacturing and packaging industries. They not only enhance the quality and durability of FIBC bags but also contribute significantly to the overall efficiency and productivity of manufacturing processes. As demand for bulk packaging solutions continues to grow, investing in advanced sealing sewing machines becomes increasingly important for manufacturers aiming to maintain a competitive edge in the market. The ability to produce reliable and robust FIBC bags systematically reinforces the importance of these specialized machines in today’s manufacturing world.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025