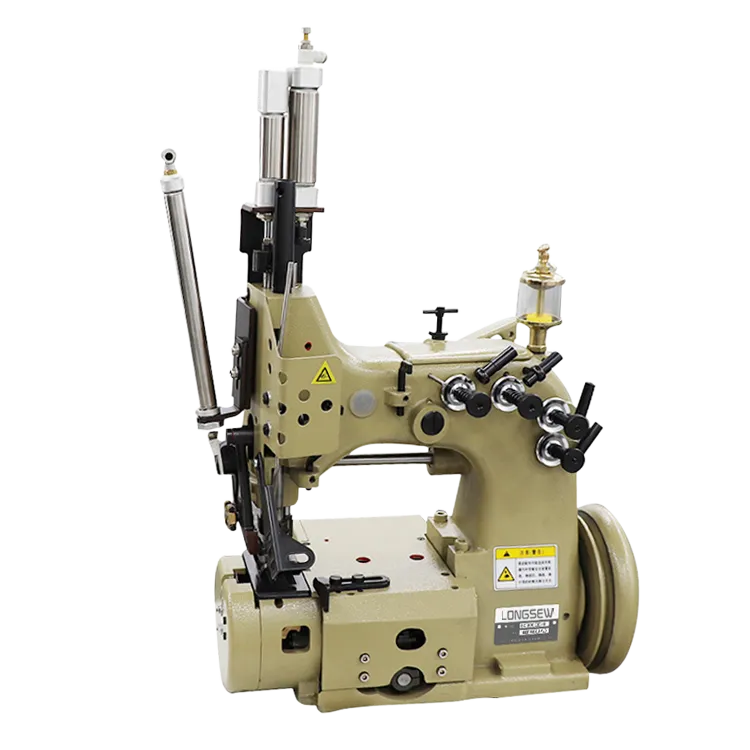

cylindrical sewing machine

The Evolution and Importance of Cylindrical Sewing Machines

Cylindrical sewing machines have revolutionized the textile and garment industries, offering solutions that cater to a wide range of sewing applications. Distinctively designed with a circular or cylindrical arm, these machines are ideal for sewing tubular materials, like sleeves, pant legs, and cuffs, which are difficult to handle with flat-bed sewing machines. The innovation behind cylindrical sewing machines has reduced production times, improved efficiency, and enhanced the quality of stitched products.

Historical Background

The journey of sewing machines began in the early 19th century, and as needs evolved, so did the machines themselves. While flat-bed machines dominated for many years, the introduction of cylindrical models marked a significant advancement in industrial sewing technology. Designed specifically for mass production, these machines allowed manufacturers to streamline operations and tackle more complex products seamlessly.

The cylindrical sewing machine can trace its roots back to the basic sewing machines of the 1800s, which had limitations in terms of fabric handling. As fashion and textile production expanded, the need for specialized machines grew. By the mid-20th century, manufacturers began focusing on creating machines that could cater to cylindrical fabric items, leading to the development of the cylindrical arm design.

Design and Operation

The cylindrical sewing machine stands out due to its unique structure. It features a rounded arm that accommodates tubular fabrics, enabling the operator to easily guide the fabric through the machine. This design not only allows for increased visibility but also enhances control over the sewing process. Operators can access hard-to-reach areas of garments, making it easier to perform intricate stitching patterns, attachments, and finishing processes.

The mechanics of cylindrical machines are built for stability and precision. Most models are equipped with advanced tension control systems, adjustable stitch lengths, and motorized components, which together ensure consistent and high-quality stitching. This level of precision is crucial in the competitive fashion industry, where even minor errors can result in significant losses.

cylindrical sewing machine

Applications

Cylindrical sewing machines are widely used in various sectors of the textile industry. One of the primary applications is in the production of casual wear, sportswear, and outerwear, where items frequently involve cylindrical shapes. For example, sewing sleeves onto t-shirts, attaching zippers to jackets, and hemming pant legs can all be accomplished efficiently using these machines.

Beyond apparel, cylindrical machines also find applications in the manufacturing of technical textiles, including automotive interiors, upholstery, and protective gear. The versatility of these machines makes them indispensable in both specialized and general textile production.

Benefits

The benefits of using cylindrical sewing machines are manifold. First and foremost, they enhance productivity. The design of these machines allows for rapid sewing without sacrificing quality, enabling manufacturers to meet high-volume demands with ease. Furthermore, they reduce fabric wastage, as the ability to sew tubular materials minimizes cut-offs.

Additionally, cylindrical machines enable the production of complex designs that might be impossible to achieve with traditional flat-bed machines. This capability offers designers more creative freedom, which is crucial in a market where unique styles and quick adaptations to trends are paramount.

Conclusion

In conclusion, cylindrical sewing machines have become a cornerstone in the textile and garment industries. Their unique design, operational efficiency, and versatility cater to a wide range of applications, making them essential for modern manufacturing processes. As the demand for high-quality and intricate designs continues to rise, it is clear that cylindrical sewing machines will remain an integral part of the industry, shaping the future of textile production for years to come. Manufacturers who invest in this technology are not only optimizing their production capacities but also positioning themselves ahead of the competition in an ever-evolving marketplace.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025