Fev . 17, 2025 13:02

Back to list

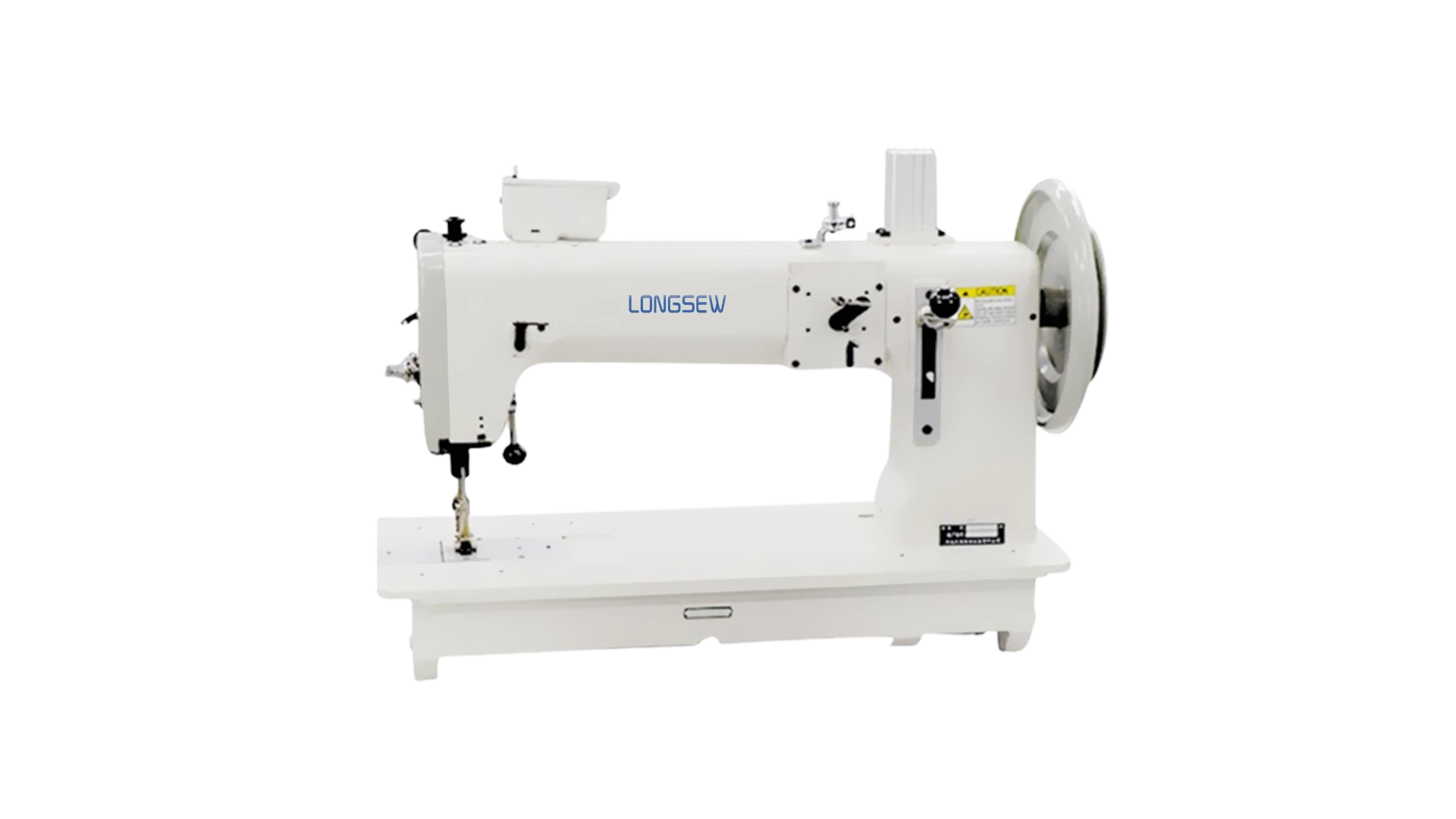

FIBC Bag / Jumbo Bag / Big Bag Double Needles Chain Stitch Sewing Machine 80700C/ 80700CD / 80700CD4H

Understanding the Compound Feed Sewing Machine Integration of Technology and Efficiency

The expertise associated with the operation of compound feed sewing machines extends into its capability to handle various types of packaging materials, ranging from light-weight plastic to heavy-duty woven sacks. This versatility is underscored by the machine’s adaptability to different sewing patterns which further ensures the integrity and security of the feed product during transportation and storage. From an authority perspective, the integration of modern technologies such as digital interface for real-time monitoring and diagnostics encapsulates the pinnacle of modern engineering within these machines. This innovation permits operators to adjust settings with precision, offering a bespoke solution tailored to specific production requirements. By tapping into the data analytics provided by these machines, businesses can make informed decisions that enhance productivity and reduce waste. Trustworthiness envelops itself in the form of standardized production outputs. The controlled sewing mechanics within these machines negate inconsistencies commonly associated with manual seam sealing, thus safeguarding product quality. Manufacturers who integrate compound feed sewing machines within their workflow are more likely to meet compliance and regulatory standards, ensuring consumer trust. In conclusion, compound feed sewing machines are more than just industrial equipment; they embody the fusion of engineering excellence, operational expertise, and technological advancements, fulfilling critical roles in the manufacturing ecosystems. Their seamless operation not only promises enhanced productivity but also heralds a new standard of reliability and trust, reinforcing their essential place in innovative feed production and packaging practices. As the demand for efficiency grows, and the requirement for robust packaging becomes ever more critical, compound feed sewing machines will increasingly become indispensable allies to manufacturers aiming to maintain competitive advantage.

The expertise associated with the operation of compound feed sewing machines extends into its capability to handle various types of packaging materials, ranging from light-weight plastic to heavy-duty woven sacks. This versatility is underscored by the machine’s adaptability to different sewing patterns which further ensures the integrity and security of the feed product during transportation and storage. From an authority perspective, the integration of modern technologies such as digital interface for real-time monitoring and diagnostics encapsulates the pinnacle of modern engineering within these machines. This innovation permits operators to adjust settings with precision, offering a bespoke solution tailored to specific production requirements. By tapping into the data analytics provided by these machines, businesses can make informed decisions that enhance productivity and reduce waste. Trustworthiness envelops itself in the form of standardized production outputs. The controlled sewing mechanics within these machines negate inconsistencies commonly associated with manual seam sealing, thus safeguarding product quality. Manufacturers who integrate compound feed sewing machines within their workflow are more likely to meet compliance and regulatory standards, ensuring consumer trust. In conclusion, compound feed sewing machines are more than just industrial equipment; they embody the fusion of engineering excellence, operational expertise, and technological advancements, fulfilling critical roles in the manufacturing ecosystems. Their seamless operation not only promises enhanced productivity but also heralds a new standard of reliability and trust, reinforcing their essential place in innovative feed production and packaging practices. As the demand for efficiency grows, and the requirement for robust packaging becomes ever more critical, compound feed sewing machines will increasingly become indispensable allies to manufacturers aiming to maintain competitive advantage.

Previous:

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025