bag closer machine parts

Understanding Bag Closer Machine Parts

Bag closer machines are essential equipment in various industries, from food packaging to textile manufacturing. These machines are designed to seal bags efficiently and securely, ensuring that products remain fresh and uncontaminated. Understanding the components that make up a bag closer machine is crucial for maintenance, troubleshooting, and enhancing operational efficiency. This article will explore the key parts of a bag closer machine and their functions.

Understanding Bag Closer Machine Parts

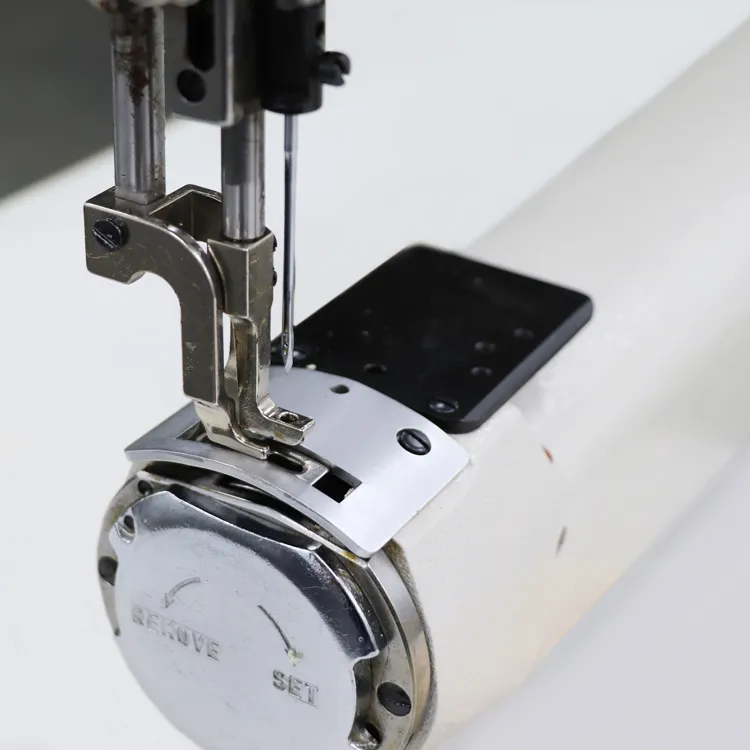

Next, the sealing head is a vital element of the bag closer machine. It applies heat, pressure, or stitching to seal the bag properly. In heat sealers, heating elements generate the necessary temperature to fuse the bag material at the seams, creating an airtight seal. For sewing-type bag closers, the stitching mechanism uses needles and thread to secure the bag. The choice between heat sealing and stitching typically depends on the type of bag material and the specific needs of the product being packaged.

bag closer machine parts

Another crucial part is the control panel. Modern bag closer machines are equipped with user-friendly control panels that allow operators to adjust settings such as sealing temperature, speed, and pressure. Some advanced models may also feature programmable settings and automatic sensors to ensure optimal performance and consistency. The control panel plays a significant role in ensuring that operators can efficiently and effectively manage the sealing process.

Additionally, the drive system is integral to the machine’s operation. It powers the feeding mechanism and the sealing head, ensuring a synchronized and efficient workflow. The drive system can include motors, belts, and gears, and its design may vary based on the machine's size and intended application. A robust drive system is crucial for maintaining the machine's longevity and reliability.

Furthermore, the body or frame of the bag closer machine provides structural support and stability. Made with durable materials, the frame ensures that the machine can withstand the rigors of continuous operation. Proper maintenance of the frame is essential to prevent misalignment and ensure smooth functioning throughout the machine’s lifespan.

In conclusion, the bag closer machine comprises several vital parts, each with a specific function that contributes to the overall performance of the machine. Understanding these components—feeding mechanism, sealing head, control panel, drive system, and body—can help operators maintain their machines better and ensure efficient packaging processes. Investing in quality parts and regular maintenance can significantly enhance productivity and product integrity in any packaging operation.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025