baffle sewing machine

The Baffle Sewing Machine Revolutionizing Textile Manufacturing

In the ever-evolving world of textile manufacturing, the baffle sewing machine stands out as a game changer, combining innovation with efficiency to enhance production processes. This specialized tool is designed to create intricate fabric designs while ensuring precision and speed, making it an essential asset for both small-scale tailors and large manufacturing units.

The primary function of the baffle sewing machine is to sew baffles into materials, typically used in products such as quilts, sleeping bags, and jackets. Baffles are essentially compartments within a fabric structure that hold insulation material, helping to maintain warmth and reduce cold spots. The sewing machine automates the process of creating these compartments in a manner that is both time-efficient and consistent, addressing a common challenge faced by textile manufacturers.

One of the standout features of the baffle sewing machine is its ability to switch between different sewing patterns with ease

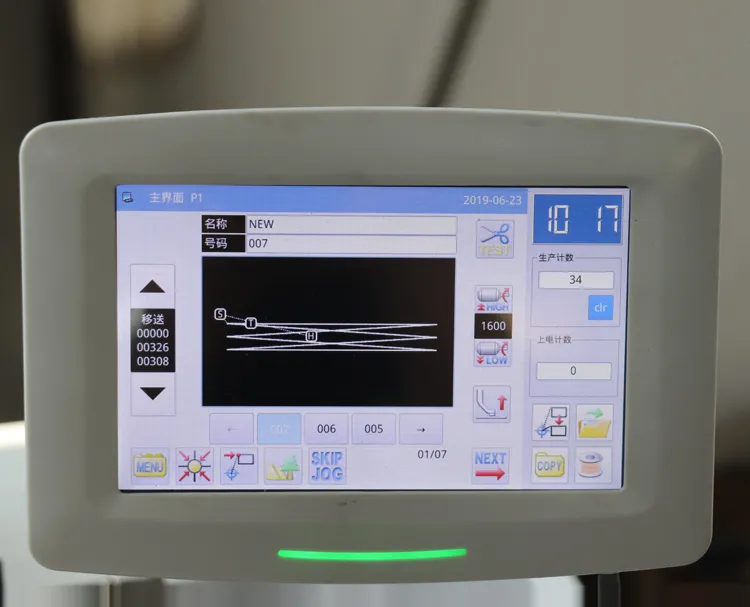

. This flexibility allows manufacturers to produce various products without the need for multiple machines or extensive downtime, thereby maximizing production efficiency. The machine is equipped with programmable settings, enabling operators to customize stitch lengths and patterns according to specific requirements, thus catering to a diverse array of products.baffle sewing machine

Moreover, the baffle sewing machine enhances the overall quality of the final product. Traditional sewing methods often resulted in uneven stitching and inconsistent insulation placement. By contrast, the automated precision of the baffle sewing machine ensures even distribution of insulation material, resulting in a higher quality end product that meets stringent industry standards.

In addition to its functional advantages, the baffle sewing machine is also designed with user-friendliness in mind. Many models feature touch-screen interfaces that allow operators to navigate settings easily, reducing the learning curve for new users. Safety features, such as automatic shut-off when a malfunction is detected, further enhance the reliability of these machines.

The introduction of the baffle sewing machine has had a significant impact on the textile industry. Manufacturers have reported reduced labor costs, improved product consistency, and shorter production cycles. These benefits enable them to remain competitive in a market that demands both quality and speed.

In summary, the baffle sewing machine represents a significant advancement in textile manufacturing technology. By combining efficiency, versatility, and precision, it allows businesses to produce high-quality insulated products while adapting to the fast-paced demands of modern consumers. As manufacturers continue to seek innovative solutions to optimize their operations, the baffle sewing machine will undoubtedly play a pivotal role in shaping the future of the textile industry.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025