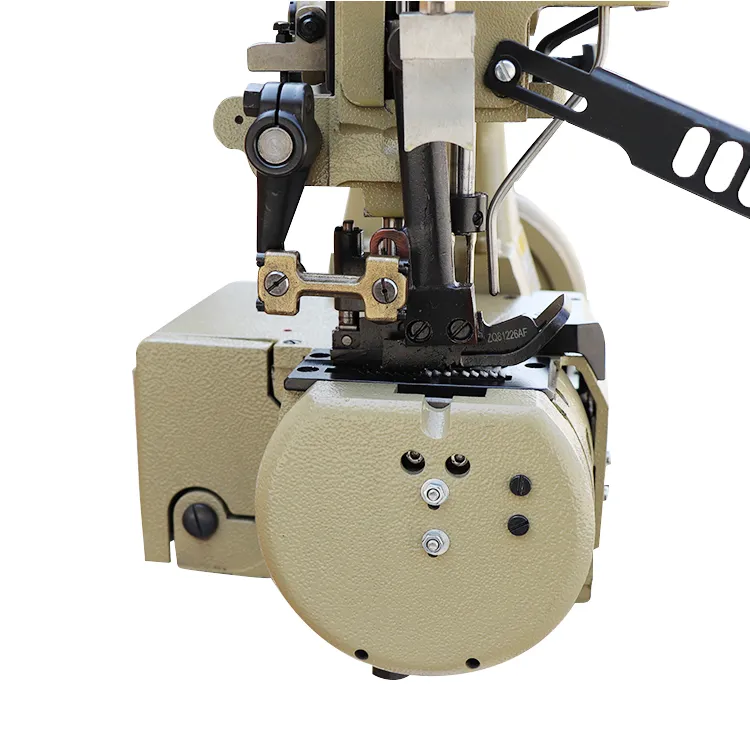

auto upholstery sewing machine walking foot

The Importance of Walking Foot Sewing Machines in Auto Upholstery

When it comes to auto upholstery, precision and durability are paramount. Cars experience a variety of stresses that can significantly affect their interiors, making it essential for upholstery to withstand wear and tear while maintaining aesthetic appeal. One of the most valuable tools in the arsenal of any auto upholsterer is the walking foot sewing machine. This specialized machine offers remarkable advantages that make it a staple in the industry.

A walking foot sewing machine is designed to handle thick materials with ease, which is particularly important in auto upholstery where multiple layers of fabric, vinyl, and padding are often sewn together. Traditional sewing machines can struggle with such heavy fabrics, leading to uneven stitches and potential damage to the materials. The walking foot mechanism allows the presser foot to move in unison with the feed dogs, ensuring that the fabric is pulled through evenly and reducing the risk of slippage. This feature is essential for producing clean, professional-looking seams in automotive interiors.

One of the most significant benefits of using a walking foot sewing machine is its ability to tackle challenging materials often found in vehicle upholstery. From leather to heavy-duty canvas and synthetic textiles, these machines can handle diverse materials without sacrificing stitch quality. This versatility is critical for upholstery projects, which may involve working with a variety of textures and finishes. When using a walking foot, upholsterers can achieve the needed strength and flexibility, making it easier to work on complex designs and detailed craftsmanship.

auto upholstery sewing machine walking foot

Another notable advantage of walking foot machines is their capability to produce custom work efficiently. Auto upholstery often requires unique designs tailored to specific vehicle models. This might involve intricate patterns or custom logos, which demand precision stitching. With a walking foot sewing machine, upholsterers can confidently create bespoke pieces that enhance the interior aesthetics of a car while ensuring durability and functional integrity.

In addition to enhancing design possibilities, walking foot sewing machines can also improve productivity. Many models are equipped with powerful motors that can sew through heavy materials at high speeds, allowing professionals to complete projects more quickly without compromising quality. This efficiency is particularly beneficial in a commercial setting, where timely turnaround is crucial for maintaining customer satisfaction and maximizing profits.

Moreover, the investment in a walking foot sewing machine can significantly reduce maintenance issues related to fabric mishaps. Since the machine is built specifically for heavy fabrics, it minimizes the risk of thread breakage and fabric damage, leading to fewer delays and a more streamlined workflow.

In summary, the walking foot sewing machine is a vital tool for anyone in the auto upholstery industry. Its ability to handle thick and varied materials, alongside its efficiency and precision, make it indispensable for creating high-quality automotive interiors. As the automotive industry continues to evolve, the need for skilled upholsterers and reliable sewing machines will remain, ensuring that this equipment will play a crucial role for years to come.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025