Fev . 02, 2025 03:05

Back to list

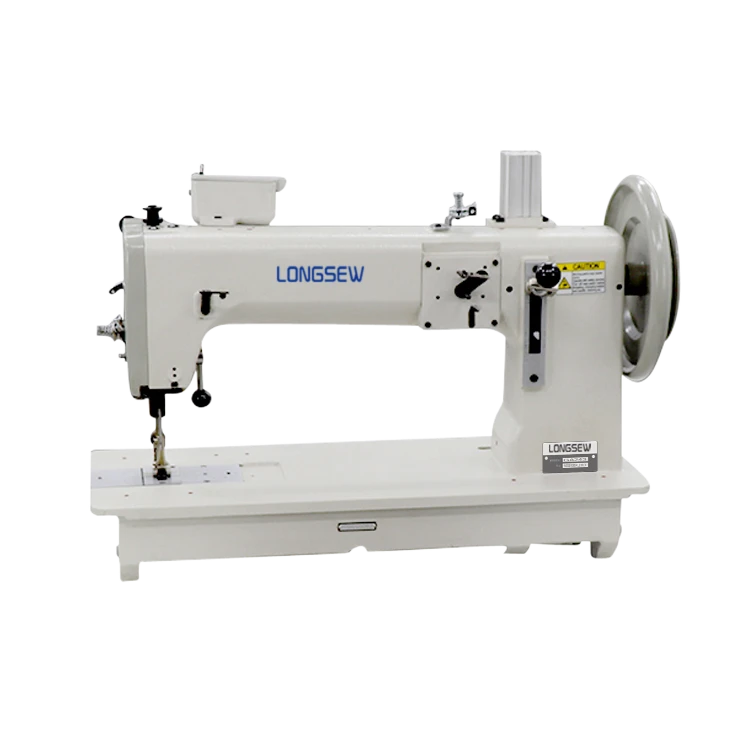

long arm stitching machine

Automatic stitching machines have revolutionized the textile industry, providing significant advancements in efficiency and precision. As a cornerstone in modern manufacturing, these machines integrate cutting-edge technology with traditional sewing processes, ensuring both speed and quality in product outputs.

As for trustworthiness, these machines are built with state-of-the-art technology that ensures reliable performance. Brands offer extensive warranties and robust after-sale service packages that reassure buyers of their dependability. Regular software updates and machine enhancements are often included in service plans, ensuring the machines keep pace with technological advancements and industry standards. In terms of product offerings, automatic stitching machines are available in a variety of models suited to different production needs, ranging from small-scale operations to large industrial configurations. Each model is designed with specific applications in mind, whether it's intricate embroidery, heavy-duty stitching, or high-speed production. Customizable features cater to diverse industries, ensuring that whether it's fashion design, home décor, or automotive seating, there’s a machine tailored to those unique requirements. Moreover, these machines have been instrumental in promoting sustainable practices. By optimizing material usage and reducing waste, automatic stitching machines contribute to eco-friendly manufacturing. Some models boast energy-efficient motors and smart sensors that adapt to material properties, further conserving resources. In conclusion, automatic stitching machines are not just tools; they are pivotal assets in modern manufacturing. Their combination of speed, reliability, and precision represents a trifecta of benefits that underscore their significance. For businesses aiming to remain competitive and innovative, investing in automatic stitching machines is a forward-thinking decision that aligns with both economic and environmental goals.

As for trustworthiness, these machines are built with state-of-the-art technology that ensures reliable performance. Brands offer extensive warranties and robust after-sale service packages that reassure buyers of their dependability. Regular software updates and machine enhancements are often included in service plans, ensuring the machines keep pace with technological advancements and industry standards. In terms of product offerings, automatic stitching machines are available in a variety of models suited to different production needs, ranging from small-scale operations to large industrial configurations. Each model is designed with specific applications in mind, whether it's intricate embroidery, heavy-duty stitching, or high-speed production. Customizable features cater to diverse industries, ensuring that whether it's fashion design, home décor, or automotive seating, there’s a machine tailored to those unique requirements. Moreover, these machines have been instrumental in promoting sustainable practices. By optimizing material usage and reducing waste, automatic stitching machines contribute to eco-friendly manufacturing. Some models boast energy-efficient motors and smart sensors that adapt to material properties, further conserving resources. In conclusion, automatic stitching machines are not just tools; they are pivotal assets in modern manufacturing. Their combination of speed, reliability, and precision represents a trifecta of benefits that underscore their significance. For businesses aiming to remain competitive and innovative, investing in automatic stitching machines is a forward-thinking decision that aligns with both economic and environmental goals.

Previous:

Latest news

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025