Sewing Machines with Automatic Button Features for Effortless Crafting

The Marvel of Automatic Button Sewing Machines

In the world of textile and garment manufacturing, efficiency and precision are key. Among the various tools that facilitate these qualities, automatic button sewing machines have emerged as a game changer. These innovative devices simplify one of the most tedious tasks in clothing production—attaching buttons—while ensuring a high level of consistency and quality.

Understanding Automatic Button Sewing Machines

Automatic button sewing machines are specialized devices designed to attach buttons to fabrics with minimal manual intervention. Unlike traditional sewing machines, which require the operator to align, sew, and secure buttons manually, these advanced machines automate the process. Equipped with a variety of features, they can handle different types and sizes of buttons and fabrics, making them versatile tools in garment production.

The basic operation involves feeding the fabric into the machine, which then automatically aligns the button in the correct position. The machine uses a series of programmed movements to sew the button in place, including securing stitches and cutting threads once the process is complete. This not only speeds up production time but also reduces the risk of human error, ensuring that buttons are consistently applied with the same tension and orientation.

Advantages of Using Automatic Button Sewing Machines

The advantages of automatic button sewing machines are numerous. Firstly, they significantly enhance productivity. In a traditional setting, a skilled worker can attach buttons but may be limited to a certain number per hour. Automatic machines, on the other hand, can complete this task much faster, allowing manufacturers to meet high demand with shorter lead times. This is particularly useful for large-scale production runs, where efficiency is critical.

Secondly, these machines offer unparalleled precision. The automation process ensures that each button is attached with the same stitch quality and consistency, reducing product defects and enhancing the overall quality of the garment. This is essential in a market where consumers expect flawless finishes and reliability.

Moreover, using automatic button sewing machines can also decrease labor costs. While the initial investment in such machinery might be high, the long-term savings can be substantial. Manufacturers can allocate human resources to more complex tasks that require creativity and craftsmanship, rather than repetitive button-sewing operations.

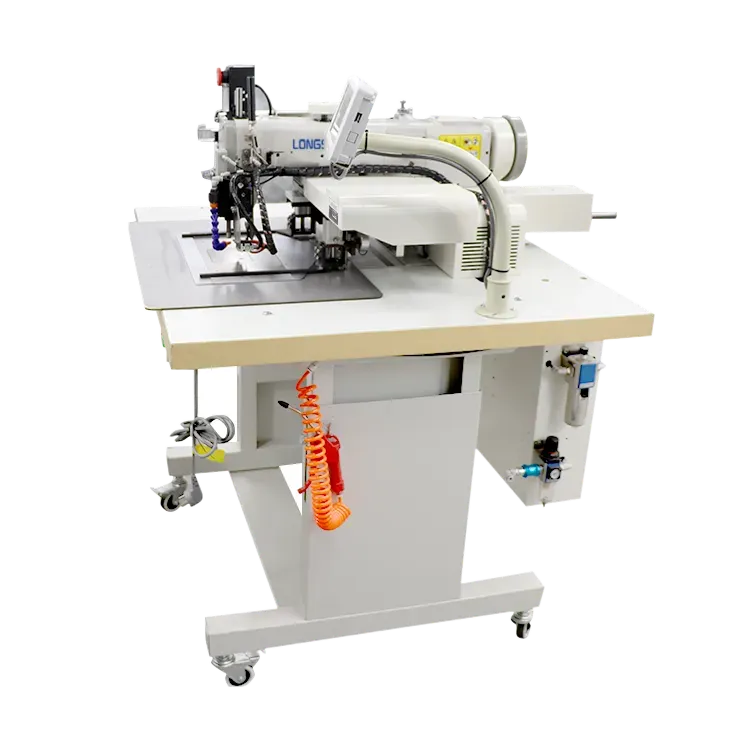

automatic button sewing machine

Versatility in Design

Another advantage is their ability to accommodate various button types and sizes. From flat buttons to shank buttons and even specialty buttons, automatic sewing machines can be programmed to recognize and sew different styles. This versatility is invaluable in today’s fashion industry, where trends can change rapidly and the demand for diverse styles can fluctuate.

Additionally, these machines can be integrated with other automated systems within a production line, creating seamless workflows that further enhance efficiency. For instance, they can be paired with fabric feeding systems, cutting machines, and inspection technologies, creating an interconnected manufacturing environment that maximizes output and minimizes waste.

The Future of Automatic Button Sewing Machines

As technology advances, the future of automatic button sewing machines looks promising. Innovations such as artificial intelligence and machine learning are beginning to influence how these machines operate. For instance, AI can be used to analyze stitching patterns, adjusting the sewing parameters in real-time for even greater adaptability and precision.

Furthermore, sustainability is becoming a critical focus in the textile industry. Machines that reduce waste and optimize material usage will be vital as manufacturers seek to lower their environmental impact. Automatic button sewing machines can play a pivotal role in this shift by minimizing fabric scraps and improving overall resource efficiency.

Conclusion

In conclusion, automatic button sewing machines represent a significant advancement in the world of garment production. Their ability to enhance productivity, ensure precision, and accommodate various designs makes them an essential tool in modern manufacturing. As technology continues to evolve, these machines are likely to become even more sophisticated, paving the way for a more efficient and sustainable future in the textile industry. The journey of sewing buttons has transformed from a manual, time-consuming task to an automated process that reflects the innovation and creativity inherent in the field of fashion and garment production.

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025

-

Revolutionizing Efficiency with Automatic Sewing MachinesNewsMar.28,2025

-

Mastering Precision with Sewing Machines and ToolsNewsMar.28,2025

-

Mastering Precision with Double Needle and Chain Stitch Sewing MachinesNewsMar.28,2025

-

Leather Sewing Machines for Every NeedNewsMar.28,2025

-

Find the Best Deals on the Adler 205 370 Sewing MachineNewsMar.28,2025

-

The Essential Guide to Overlock Sewing MachinesNewsMar.18,2025