Feb . 18, 2025 08:49

Back to list

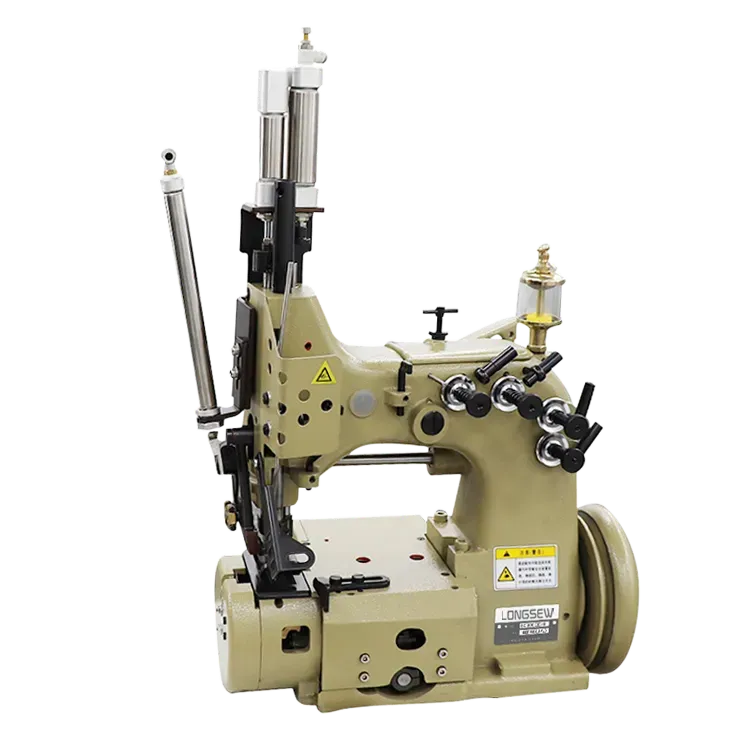

industrial sewing machine straight and zig zag

Navigating the complex world of machinery pricing can be daunting for both newcomers and seasoned industry professionals. Among various machinery, the zig zag machine stands out due to its versatile applications across different sectors. Understanding the price dynamics of zig zag machines involves exploring factors such as quality, brand reputation, technological advancements, and market demands.

To choose the right zig zag machine, consider the specific needs of your operation. Small-scale operations may benefit from more affordable, basic models, whereas large-scale productions might require machines with advanced capabilities. Evaluating the total cost of ownership, rather than just the upfront price, ensures that you consider all factors including maintenance, operation, and potential expansion needs. Consulting with industry experts and reading reviews from other users can provide valuable insights. Experience shared by others can highlight potential issues and benefits, aiding you in making an informed decision. Trustworthy reviews usually come from users who have a history of employing various machines and can compare different models based on practical usage. Ultimately, when deciding on a zig zag machine, prioritize your priorities. Whether it’s the premium for established brands, added features for operational efficiency, or a strategic purchase during low demand, aligning your choice with your business objectives is crucial. A well-researched decision not only saves money but also enhances your operation’s capability, giving you a competitive edge in the industry. In summary, the expertise required to navigate the zig zag machine market emphasizes understanding the interplay between cost and value. By considering factors such as manufacturer reputation, technological advancements, and market trends, businesses can make authoritative and trustworthy purchasing decisions that align with their specific production needs.

To choose the right zig zag machine, consider the specific needs of your operation. Small-scale operations may benefit from more affordable, basic models, whereas large-scale productions might require machines with advanced capabilities. Evaluating the total cost of ownership, rather than just the upfront price, ensures that you consider all factors including maintenance, operation, and potential expansion needs. Consulting with industry experts and reading reviews from other users can provide valuable insights. Experience shared by others can highlight potential issues and benefits, aiding you in making an informed decision. Trustworthy reviews usually come from users who have a history of employing various machines and can compare different models based on practical usage. Ultimately, when deciding on a zig zag machine, prioritize your priorities. Whether it’s the premium for established brands, added features for operational efficiency, or a strategic purchase during low demand, aligning your choice with your business objectives is crucial. A well-researched decision not only saves money but also enhances your operation’s capability, giving you a competitive edge in the industry. In summary, the expertise required to navigate the zig zag machine market emphasizes understanding the interplay between cost and value. By considering factors such as manufacturer reputation, technological advancements, and market trends, businesses can make authoritative and trustworthy purchasing decisions that align with their specific production needs.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025