Feb . 20, 2025 01:39

Back to list

zig zag machine head price

The zig zag sewing machine head, an integral component of advanced textile manufacturing, has become a focal point for many professionals seeking optimal performance in sewing tasks. The price of these vital machine components can vary significantly, depending on a variety of factors such as brand, functionality, and added technological features. Understanding these variations is crucial for businesses aiming to balance quality and budget effectively.

The material composition of the machine head also influences its price. Heavy-duty machine heads constructed from robust materials like stainless steel or titanium are designed to withstand rigorous operations, ensuring durability and stable performance under high pressure. These are particularly valuable in industrial settings where machines operate for extended periods. The hefty price of such durable models is a testament to their longevity and sustained performance, making them a preferred choice for industries that prioritize durability over short-term savings. Warranty and post-purchase services add another dimension to the pricing considerations. Machine heads that come with a comprehensive warranty and access to a wide network of service centers may appear costlier but offer the security of reliable customer support and assurance in case of mechanical failures. These service packages are particularly appealing to enterprises where machine downtime can result in significant financial losses, thus emphasizing the importance of evaluating post-purchase support when considering the overall cost of ownership. Importantly, purchasing from authorized distributors or official outlets ensures authenticity and access to official service benefits, a critical consideration for maintaining machine integrity and performance. The premium pricing in such outlets reflects not only the quality and authenticity of the product but also the peace of mind that comes with guaranteed support and service, which is crucial for maintaining operational continuity. In conclusion, the price of a zig zag machine head is a reflection of various key elements - brand reputation, functionality, technological advancements, material durability, and after-sales service. A strategic approach towards understanding these components can aid businesses in making informed decisions that align with their production needs and financial goals. Prioritizing quality and investing in advanced features often results in long-term savings and improved operational efficiency, proving advantageous for manufacturers aiming for competitive edge and sustained growth in the textile industry.

The material composition of the machine head also influences its price. Heavy-duty machine heads constructed from robust materials like stainless steel or titanium are designed to withstand rigorous operations, ensuring durability and stable performance under high pressure. These are particularly valuable in industrial settings where machines operate for extended periods. The hefty price of such durable models is a testament to their longevity and sustained performance, making them a preferred choice for industries that prioritize durability over short-term savings. Warranty and post-purchase services add another dimension to the pricing considerations. Machine heads that come with a comprehensive warranty and access to a wide network of service centers may appear costlier but offer the security of reliable customer support and assurance in case of mechanical failures. These service packages are particularly appealing to enterprises where machine downtime can result in significant financial losses, thus emphasizing the importance of evaluating post-purchase support when considering the overall cost of ownership. Importantly, purchasing from authorized distributors or official outlets ensures authenticity and access to official service benefits, a critical consideration for maintaining machine integrity and performance. The premium pricing in such outlets reflects not only the quality and authenticity of the product but also the peace of mind that comes with guaranteed support and service, which is crucial for maintaining operational continuity. In conclusion, the price of a zig zag machine head is a reflection of various key elements - brand reputation, functionality, technological advancements, material durability, and after-sales service. A strategic approach towards understanding these components can aid businesses in making informed decisions that align with their production needs and financial goals. Prioritizing quality and investing in advanced features often results in long-term savings and improved operational efficiency, proving advantageous for manufacturers aiming for competitive edge and sustained growth in the textile industry.

Previous:

Next:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

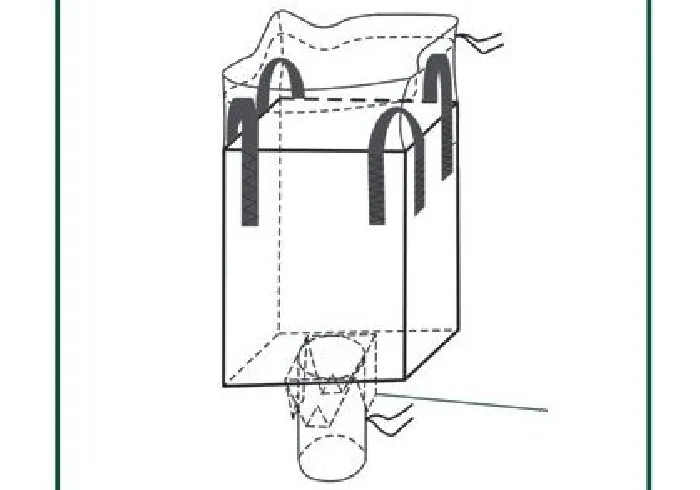

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025