Feb . 20, 2025 02:37

Back to list

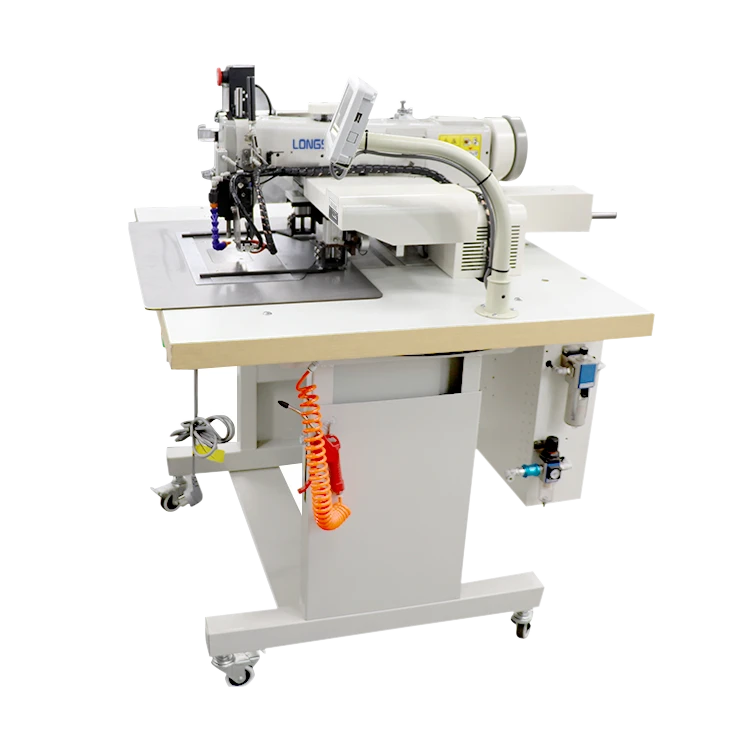

zigzag and overlock machine

In the textile and garment industry, the zigzag and overlock machine stands as a crucial innovation, revolutionizing the way we think about fabric edging and stitching. Understanding the mechanics and benefits of these machines can offer unparalleled advantages to both amateur enthusiasts and seasoned professionals in the field.

Investing in a high-quality zigzag or overlock machine also involves understanding the nuances of machine maintenance to ensure longevity and consistent performance. Regular cleaning, timely oiling, and professional servicing can greatly extend the life of these machines. Knowledge of thread tension adjustments and fabric-specific settings can also impact the quality of the finished product, thus making comprehensive knowledge essential for maximizing the potential of these machines. Training and expertise in utilizing these machines can often be the dividing line between amateur and professional outcomes. As more designers seek unique textures and durable finishes in their creations, in-depth knowledge of both zigzag and overlock machines becomes not only beneficial but necessary. Professionals in the textile and apparel industry who excel with these machines often provide training or workshops, further expanding the community's skill set in machine operation and maintenance. Trustworthy manufacturers and retailers build their reputations on the reliability and performance of their zigzag and overlock machines. It’s crucial for buyers to choose reputable brands known for their engineering excellence and customer support. Reading reviews, consulting peers in the industry, and attending trade shows can provide insights into the best models and brands currently available. With technological advances, some modern machines now offer digital features and computerized interfaces, which allow for more precise control and customization. These advancements provide improved ease of use and broaden the capabilities of traditional zigzag and overlock machines. For industrial applications, the return on investment can be considerable as these machines often contribute to faster production times and reduced labor costs. In a world where speed to market is a competitive advantage, the efficiency provided by these machines is invaluable. In conclusion, the zigzag and overlock machine are indispensable tools in the realm of fashion and textile production. Their utilization not only enhances the structural integrity and aesthetic appeal of garments but also supports the creativity and efficiency that the modern apparel industry demands. Whether for small-scale designers or large manufacturing units, investing in these machines and the expertise to operate them effectively can significantly impact the quality and success of textile endeavors.

Investing in a high-quality zigzag or overlock machine also involves understanding the nuances of machine maintenance to ensure longevity and consistent performance. Regular cleaning, timely oiling, and professional servicing can greatly extend the life of these machines. Knowledge of thread tension adjustments and fabric-specific settings can also impact the quality of the finished product, thus making comprehensive knowledge essential for maximizing the potential of these machines. Training and expertise in utilizing these machines can often be the dividing line between amateur and professional outcomes. As more designers seek unique textures and durable finishes in their creations, in-depth knowledge of both zigzag and overlock machines becomes not only beneficial but necessary. Professionals in the textile and apparel industry who excel with these machines often provide training or workshops, further expanding the community's skill set in machine operation and maintenance. Trustworthy manufacturers and retailers build their reputations on the reliability and performance of their zigzag and overlock machines. It’s crucial for buyers to choose reputable brands known for their engineering excellence and customer support. Reading reviews, consulting peers in the industry, and attending trade shows can provide insights into the best models and brands currently available. With technological advances, some modern machines now offer digital features and computerized interfaces, which allow for more precise control and customization. These advancements provide improved ease of use and broaden the capabilities of traditional zigzag and overlock machines. For industrial applications, the return on investment can be considerable as these machines often contribute to faster production times and reduced labor costs. In a world where speed to market is a competitive advantage, the efficiency provided by these machines is invaluable. In conclusion, the zigzag and overlock machine are indispensable tools in the realm of fashion and textile production. Their utilization not only enhances the structural integrity and aesthetic appeal of garments but also supports the creativity and efficiency that the modern apparel industry demands. Whether for small-scale designers or large manufacturing units, investing in these machines and the expertise to operate them effectively can significantly impact the quality and success of textile endeavors.

Previous:

Next:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025