Efficient Stitching Solutions for Woven Sack Production Machines

The Evolution and Importance of Woven Sack Stitching Machines

Woven sack stitching machines are essential devices in the packaging industry, designed specifically for sealing and securing bags made from woven materials. These machines have evolved significantly over the years, driven by advancements in technology and the growing demand for efficient packaging solutions in various sectors, including agriculture, construction, and food production.

The Functionality of Woven Sack Stitching Machines

At their core, woven sack stitching machines are designed to seal the open ends of woven polypropylene or other types of woven sacks, which are commonly used for packaging grains, fertilizers, and other bulk materials. The primary function of these machines is to ensure that the contents of these bags are securely enclosed, preventing spillage and contamination during storage and transportation.

Woven sack stitching machines utilize various stitching techniques, including single-thread and double-thread stitching. Single-thread stitching is suitable for lighter bags, providing a quick and cost-effective sealing solution. In contrast, double-thread stitching offers greater durability, making it ideal for heavier bags that may experience a greater degree of stress during handling.

Innovations in Woven Sack Stitching Technology

The evolution of woven sack stitching machines has been characterized by a series of innovations aimed at improving efficiency and productivity

. Modern machines are equipped with advanced features such as programmable logic controllers (PLCs), which allow users to customize stitching length, speed, and tension according to the specific requirements of the bags being processed.Moreover, recent advancements have brought about the introduction of automated stitching machines. These machines are capable of integrating seamlessly into larger packaging lines, offering a cohesive and efficient workflow. Automation has reduced the need for manual labor, leading to lower production costs and increased output. Additionally, many of these machines now feature user-friendly interfaces that facilitate easy operation and maintenance, making them accessible even to those with limited technical expertise.

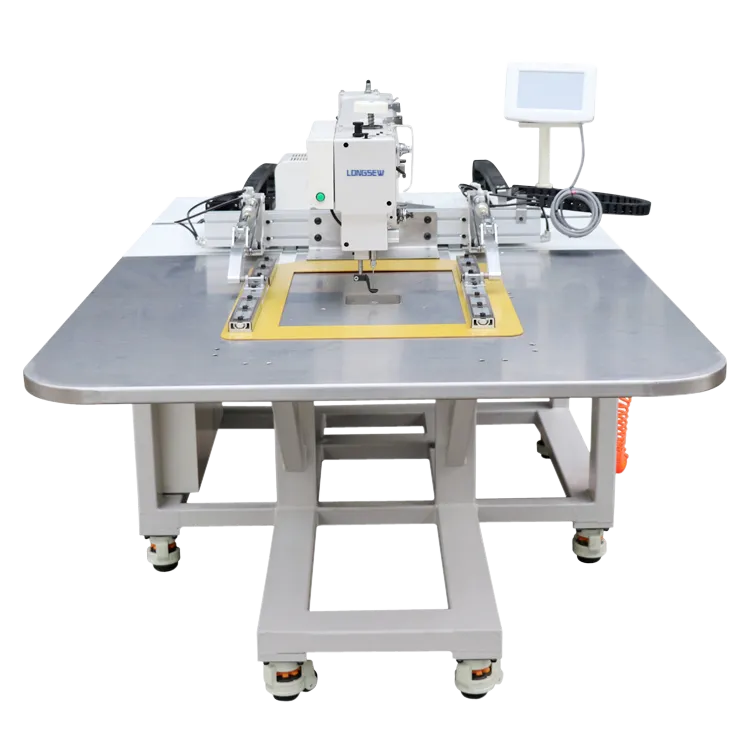

woven sack stitching machine

The Role of Woven Sack Stitching Machines in Sustainability

As global awareness of environmental issues grows, the packaging industry is increasingly seeking sustainable solutions. Woven sacks, particularly those made from recyclable polypropylene, are gaining traction as an eco-friendly alternative to plastic bags. Woven sack stitching machines play a vital role in this transition by ensuring that these bags can be used efficiently and effectively throughout their lifecycle.

Furthermore, the durability of woven sacks, when properly stitched, extends their usability. This longevity not only contributes to reducing waste but also fits well with the principles of a circular economy, where materials are reused and recycled whenever possible. By investing in efficient stitching technology, businesses can enhance their sustainability efforts while simultaneously meeting the demands of a growing market.

The Future of Woven Sack Stitching Machines

Looking ahead, the future of woven sack stitching machines appears to be bright, with continued innovations on the horizon. Manufacturers are exploring the integration of artificial intelligence (AI) and machine learning to optimize stitching processes further, enhance quality control, and predict maintenance needs proactively. Such advancements could lead to even higher levels of automation and efficiency within the packaging industry.

Moreover, the growing trend toward customization in packaging solutions suggests that woven sack stitching machines will adapt to produce bags of varying sizes and designs, catering to diverse consumer preferences. This adaptability will be crucial in helping manufacturers remain competitive in a dynamic marketplace.

In conclusion, woven sack stitching machines are not merely tools for sealing bags; they are pivotal to the efficiency, sustainability, and innovation of the packaging industry. As technology continues to advance, these machines will undoubtedly evolve, ensuring that they meet the changing needs of various industries while contributing to a more sustainable future.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025