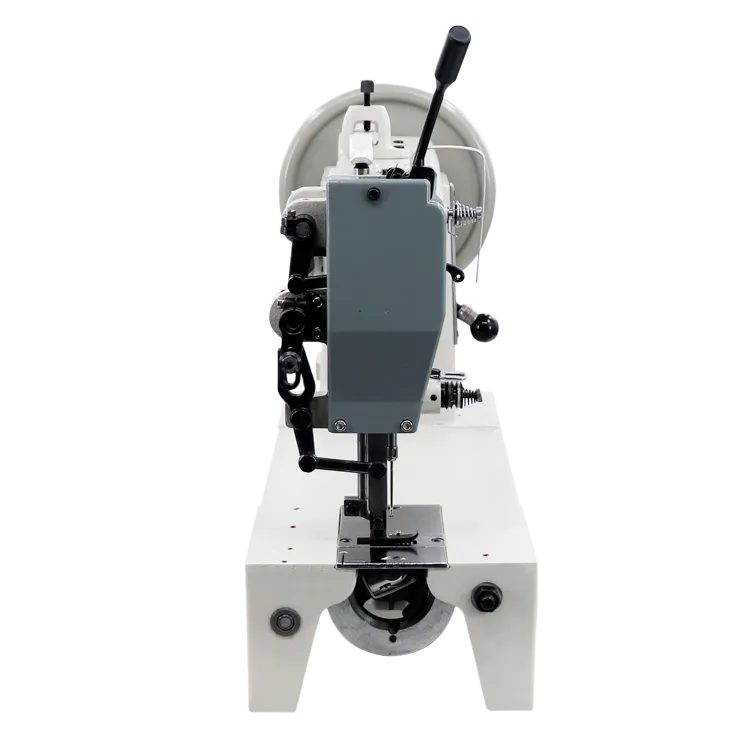

woven sack stitching machine

The Importance of Woven Sack Stitching Machines in Modern Packaging

In today's fast-paced industrial environment, packaging plays a crucial role in ensuring the safe transport and storage of goods. Among the various packaging materials available, woven sacks have gained immense popularity due to their strength, durability, and versatility. These sacks are often used to package agricultural products, chemicals, construction materials, and pet food, among other items. At the core of the production of these woven sacks is the woven sack stitching machine, a technological marvel that streamlines the stitching process and enhances overall efficiency in packaging.

What is a Woven Sack Stitching Machine?

A woven sack stitching machine is a specialized device designed to close the open ends of woven polypropylene or polyethene bags. These machines use various stitching methods to secure the bag's contents effectively. The stitching can be done using single thread, double thread, or even with the application of heat to fuse the fabric, depending on the requirements of the bag and its contents. The stitching machines can be adjusted to accommodate different sack sizes, stitching patterns, and thread types, making them highly versatile for manufacturers.

The Technology Behind Woven Sack Stitching Machines

Modern woven sack stitching machines come equipped with advanced technology that enhances their functionality. Many machines feature automatic feeding systems that enable a continuous flow of sacks, significantly increasing production speed. Additionally, some models are integrated with sensors that detect bag alignment and positioning, ensuring precise stitching. These advancements minimize human intervention, reducing the risk of errors and enhancing productivity.

The use of servo motors in these machines contributes to better energy efficiency and quiet operation. Furthermore, some machines are equipped with user-friendly interfaces that allow operators to easily adjust settings and monitor production, making it easier to achieve optimal results.

Benefits of Using Woven Sack Stitching Machines

1. Increased Efficiency One of the most significant advantages of using woven sack stitching machines is their ability to increase production efficiency. With faster stitching speeds and automatic operation, companies can produce a vast number of woven sacks in a short amount of time, catering to high market demand.

woven sack stitching machine

2. Cost-Effectiveness By reducing labor costs and minimizing material wastage, these machines contribute to overall cost savings. Their high-output capability allows businesses to remain competitive in pricing while maintaining profitability.

3. Consistency and Quality The precision and reliability of woven sack stitching machines ensure that each sack is stitched uniformly. This consistency is crucial for maintaining product quality, as properly stitched bags are less likely to tear or leak, thereby protecting the contents.

4. Versatility As mentioned earlier, these machines can accommodate various sack sizes and materials. This versatility allows manufacturers to produce different types of bags for diverse industries without needing multiple machines.

5. Enhanced Safety Automated machines reduce the need for manual handling, thereby minimizing the risk of injuries in the workplace. Moreover, the consistent closure of bags ensures that hazardous materials are securely contained, reducing the risk of spills and accidents.

The Future of Woven Sack Stitching Machines

As industries continue to evolve, the demand for efficient and reliable packaging solutions will grow. The woven sack stitching machine market is expected to expand, driven by innovations in automation and technology. Future developments may include smarter systems with integrated IoT capabilities, allowing for real-time monitoring and data analysis. This can help manufacturers optimize their operations and respond swiftly to changing market demands.

Additionally, as sustainability becomes a focal point of manufacturing practices, there may be a push towards eco-friendly materials in woven sack production. Stitching machines that can work with biodegradable materials or offer minimal waste solutions will likely gain traction.

Conclusion

In summary, woven sack stitching machines play an indispensable role in the modern packaging landscape. Their ability to enhance efficiency, reduce costs, and ensure quality makes them vital for manufacturers across various sectors. As technology advances and the industry adapts to new challenges, these machines will continue to evolve, further solidifying their significance in a competitive market. With the right investment in such machinery, companies can look forward to a more streamlined, sustainable, and successful future in packaging.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025