Feb . 14, 2025 21:25

Back to list

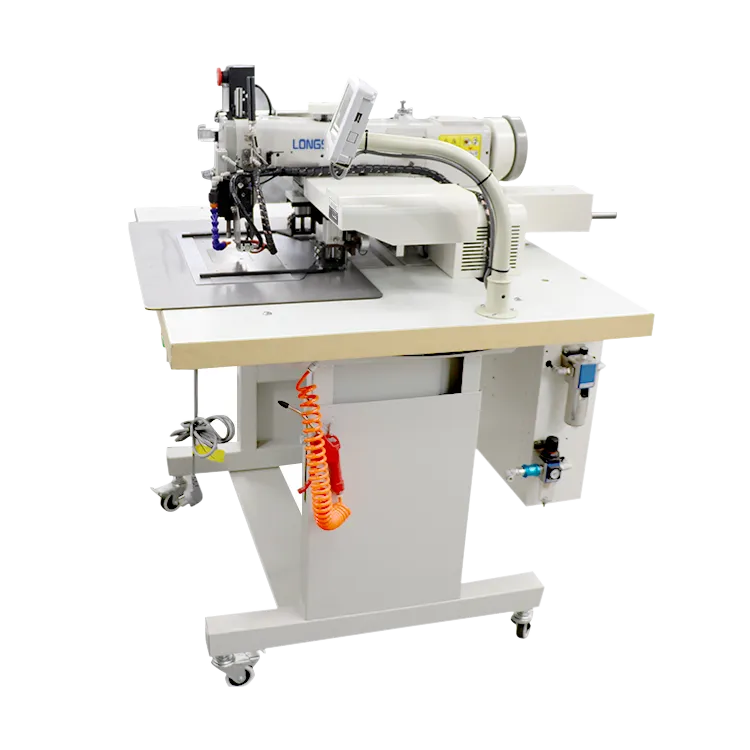

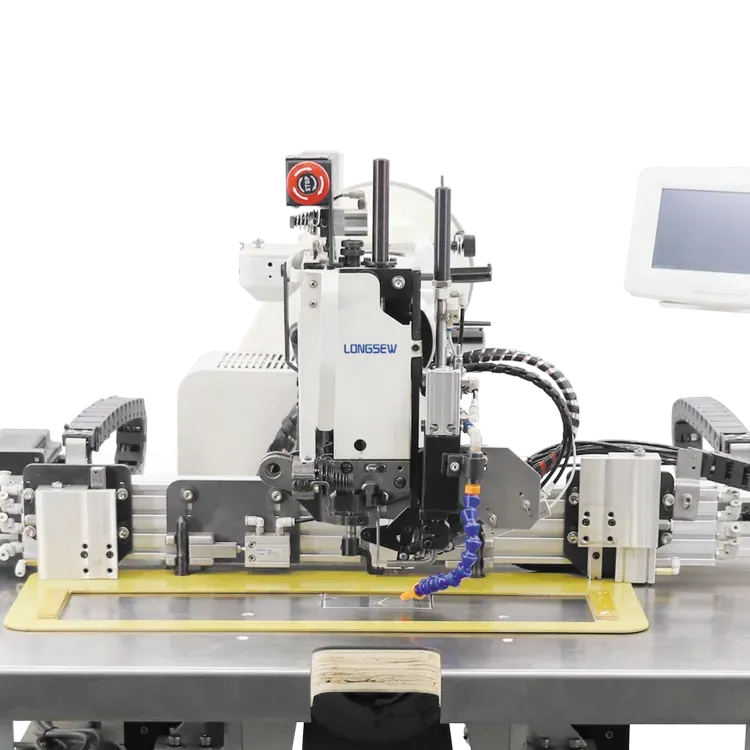

Fishing Net Hauling Rope Single Needle 3 Threads Overedging Sewing Machine 81500CZ

In the ever-evolving landscape of industrial sewing, one machine has emerged as integral to the packaging and logistics sectors the woven sack bag sewing machine. This specialized equipment has transformed the way businesses handle bulk goods, promising efficiency, durability, and seamless productivity. With the rise in demand for reliable storage and transport solutions, exploring the nuances of these machines unveils their indispensable worth.

For those seeking authoritative insights, industry leaders articulate that the longevity and maintenance of these machines are also key considerations. Durable construction and availability of spare parts are crucial factors affecting the lifetime of a sewing machine and its ROI. Companies must ensure they are partnering with reputable manufacturers who provide robust after-sales support and comprehensive warranties. Furthermore, customer testimonials reveal a strong correlation between the implementation of woven sack bag sewing machines and enhanced trustworthiness within supply chains. Clients report higher satisfaction levels, as these machines contribute to timely deliveries and maintain the quality of goods, underscoring credibility and reliability. This translates into improved client relationships and a stronger market position. Innovation in woven sack bag sewing machines also caters to environmental concerns. As global consciousness shifts towards sustainability, manufacturers are now offering machines that support eco-friendly packaging solutions. The adaptability of these machines to work with biodegradable and recyclable materials is a significant step forward, aligning operational efficiency with sustainable practices. In sum, woven sack bag sewing machines represent a vital investment for businesses looking to maintain a competitive edge. From enhancing productivity through robust operations to aligning with modern sustainability standards, these machines play a fundamental role in contemporary industrial settings. Decision-makers leveraging these insights are better positioned to make informed purchasing choices, ultimately reflecting positively in their organizational success and market reputation. As industries continue to evolve, these machines stand as a testament to the seamless integration of tradition and innovation in industrial automation.

For those seeking authoritative insights, industry leaders articulate that the longevity and maintenance of these machines are also key considerations. Durable construction and availability of spare parts are crucial factors affecting the lifetime of a sewing machine and its ROI. Companies must ensure they are partnering with reputable manufacturers who provide robust after-sales support and comprehensive warranties. Furthermore, customer testimonials reveal a strong correlation between the implementation of woven sack bag sewing machines and enhanced trustworthiness within supply chains. Clients report higher satisfaction levels, as these machines contribute to timely deliveries and maintain the quality of goods, underscoring credibility and reliability. This translates into improved client relationships and a stronger market position. Innovation in woven sack bag sewing machines also caters to environmental concerns. As global consciousness shifts towards sustainability, manufacturers are now offering machines that support eco-friendly packaging solutions. The adaptability of these machines to work with biodegradable and recyclable materials is a significant step forward, aligning operational efficiency with sustainable practices. In sum, woven sack bag sewing machines represent a vital investment for businesses looking to maintain a competitive edge. From enhancing productivity through robust operations to aligning with modern sustainability standards, these machines play a fundamental role in contemporary industrial settings. Decision-makers leveraging these insights are better positioned to make informed purchasing choices, ultimately reflecting positively in their organizational success and market reputation. As industries continue to evolve, these machines stand as a testament to the seamless integration of tradition and innovation in industrial automation.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025