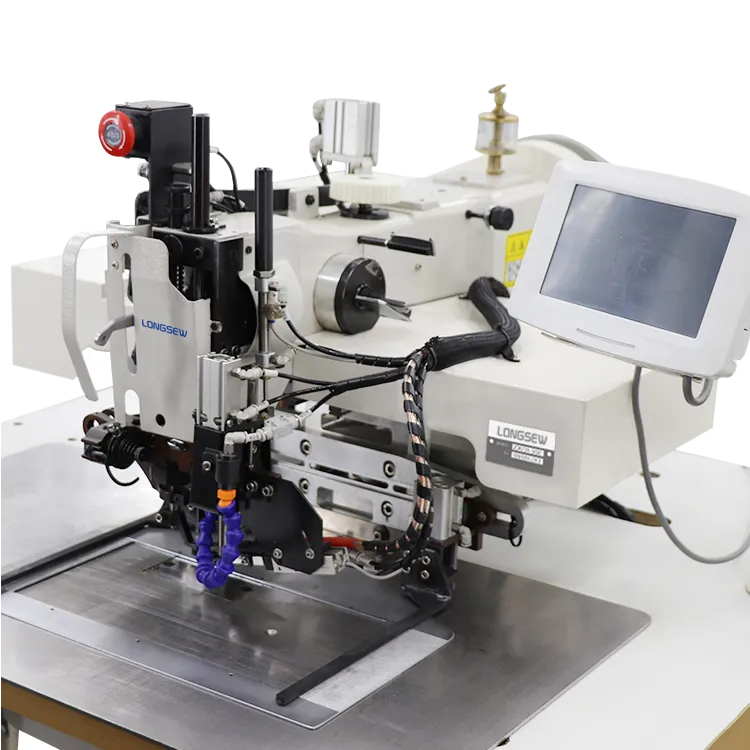

woven bag sewing machine

Understanding Woven Bag Sewing Machines

Woven bag sewing machines are essential tools in the textile industry, particularly for manufacturers specializing in the production of woven bags. These bags, made from polypropylene or other synthetic materials, are widely used for packaging and transporting a variety of goods, including agricultural products, construction materials, and consumer goods. As the demand for eco-friendly and reusable packaging rises, the significance of specialized sewing machines in the production process becomes increasingly apparent.

A woven bag sewing machine is designed specifically to handle the unique characteristics of woven fabrics. The materials used in woven bags are typically thick and durable, requiring robust sewing machines with powerful motors to handle the heavier workloads. These machines are equipped with high-speed stitching capabilities, often reaching speeds of up to 2,500 stitches per minute. This ensures that manufacturers can produce large quantities of bags efficiently without compromising on quality.

The sewing process for woven bags usually involves several stages, including cutting, stitching, and finishing. A good quality woven bag sewing machine should offer versatility, allowing operators to adjust settings for different bag sizes and thicknesses. Features such as automatic thread tension control, programmable stitch length, and the ability to sew multiple layers of fabric are crucial for ensuring that sewn seams are strong and durable.

woven bag sewing machine

Additionally, many modern woven bag sewing machines come with computerized systems that streamline the manufacturing process. These machines allow for automated programming, which not only reduces the potential for human error but also enhances production speed. Operators can store various bag patterns in the machine’s memory, making it easier to switch between production lines without the need for extensive recalibration.

Maintenance plays a critical role in the longevity and performance of woven bag sewing machines. Regular cleaning, oiling, and parts replacement are essential practices that ensure machines run smoothly and efficiently. Manufacturers should invest in training operators to perform routine maintenance and troubleshoot common issues to minimize downtime.

In conclusion, woven bag sewing machines are vital in meeting the increasing demand for sustainable packaging solutions. Their specialized design and advanced features facilitate the efficient production of durable woven bags, contributing to the functionality and appeal of these often-overlooked products. As industries continue to shift towards more environmentally friendly practices, the role of these machines will only grow in importance, supporting a shift towards smarter and more sustainable manufacturing processes.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025