Why Heavy Duty Computerized Sewing Machines Are Worth the Investment

While heavy-duty computerized sewing machines often come with a higher price tag than their manual counterparts, they represent a smart investment for anyone serious about their sewing business or craft. The upfront cost is quickly offset by the long-term benefits these machines bring in terms of efficiency, versatility, and durability.

Heavy Duty Computerized Sewing Machines Help to Increased Production Efficiency

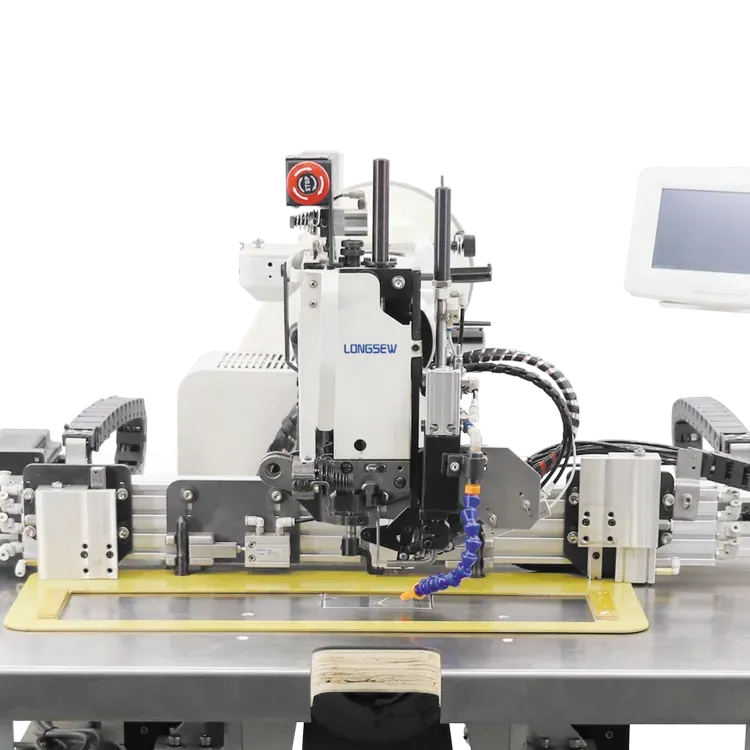

One of the biggest selling points of a computerized pattern sewing machine is its ability to speed up production without sacrificing quality. Automatic features such as stitch selection, tension control, and needle positioning save time and effort, allowing sewers to complete projects faster. This is particularly valuable for professionals who rely on meeting deadlines and increasing throughput.

Moreover, the powerful motors and robust construction of these machines enable them to sew through thicker, tougher fabrics without strain. This eliminates the need for multiple machines and reduces downtime, further enhancing productivity.

Heavy Duty Computerized Sewing Machines Help to Increased Precision and Quality

For anyone working with high-quality or delicate fabrics, the precision of a computerized sewing machine is invaluable. These machines offer consistent stitch quality, ensuring that each seam is neat and uniform. Whether you’re working on custom garments, intricate quilts, or high-end upholstery, the reliability of a computerized machine ensures that every stitch is executed flawlessly.

Additionally, the advanced stitching capabilities allow users to execute complex patterns and techniques that would be challenging to achieve manually. The machine’s precision reduces the risk of mistakes and wasted material, ultimately leading to cost savings.

Versatility and Customization of Heavy Duty Computerized Sewing Machines

Heavy duty industrial sewing machines are incredibly versatile. They come equipped with a range of features that cater to different types of sewing, including quilting, embroidery, garment construction, and even heavy-duty tasks like leatherwork. The ability to easily switch between different tasks without needing separate machines or complicated setups saves both time and money.

Many models also offer the option to program custom stitch patterns, making them ideal for users who want to create unique designs or streamline their workflow. This level of customization adds even more value, as it gives users the flexibility to work on a variety of projects without limitations.

Long-Term Durability of Heavy Duty Computerized Sewing Machines

Heavy duty sewing machines are built to last. These machines are designed with high-quality materials and powerful motors that can withstand years of heavy use. In the long run, they require fewer repairs and maintenance compared to lower-end models, making them a more cost-effective choice for professionals and serious hobbyists.

Furthermore, the ability to upgrade or modify the machine with additional features, attachments, or software ensures that your investment remains relevant and adaptable as your sewing needs evolve.

In conclusion, while the upfront cost of a heavy duty pattern sewing machine may be higher, the benefits far outweigh the initial expense. Increased efficiency, superior precision, versatility, and long-term durability make these machines an essential investment for anyone looking to elevate their sewing projects or business. By improving the quality of work and streamlining the production process, these machines quickly pay for themselves and offer lasting value for years to come.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025