Why Choose Fibc Sewing Machine

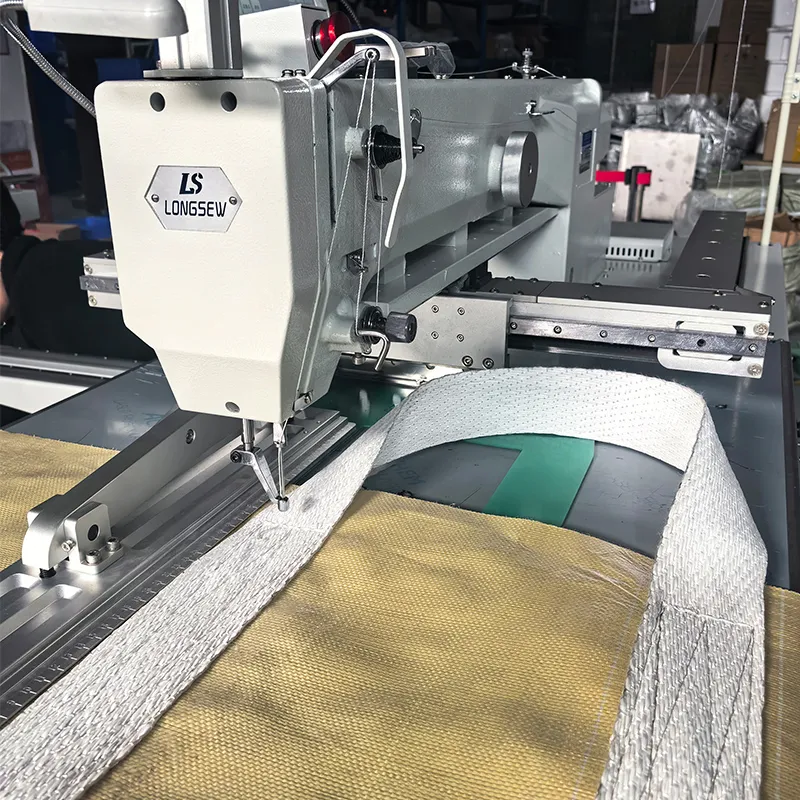

In modern industrial production and logistics transportation, giant bags are becoming increasingly important, which is inseparable from the use of fiber container bags (FIBC). The production of these powerful giant bags that can hold a large number of products depends largely on advanced fiber container bag sewing machines. The so-called FIBC sewing machines, also known as jumbo bag sewing machine, extra large sewing machine trolley bag, and big bag sewing machine, have greatly improved production efficiency and product quality.

Advantages of fibc sewing machines

These fibc sewing machines are specially designed to handle large and durable materials, so that giant bags can maintain high quality and high strength during the production process, thereby effectively responding to complex transportation and storage needs. It is worth mentioning that super large sewing machines can not only handle giant bags required by general industry, but also be used to make extra large sewing machine trolley bags, providing a variety of options and possibilities for personal and commercial fields.

The fibc sewing machine is a sewing equipment specially used to make large container bags for various industrial purposes. With the growing demand for global logistics and transportation of various materials, the use of container bags has become more and more common. Therefore, fibc sewing machines play a very important role in the industrial production process. This article will introduce the many advantages of this equipment and explore its importance in modern industry.

First of all, fibc sewing machines are extremely efficient. Compared with traditional handmade or simple sewing machines, fibc sewing machines are able to produce high-quality container bags in a short time. They can automatically perform a variety of sewing processes, such as bottom edge sealing, sewing reinforcement tape, sewing zippers, etc., which greatly improves production efficiency. This high efficiency not only meets the needs of mass production, but also reduces production costs, allowing enterprises to occupy a favorable position in the fierce market competition. In addition, high-efficiency production also means that products can be put on the market faster to meet the urgent needs of customers, thereby further improving the market response speed of enterprises.

Secondly, stable quality is another major advantage of fibc sewing machines. The machine equipment can maintain consistent sewing standards during operation, ensuring that the sewing strength of each container bag is uniform, strong and durable. This consistency in quality is difficult to achieve with manual sewing. Especially when dealing with large-scale production, the use of fibc sewing machines can greatly reduce human errors and ensure that each batch of products meets the standards. Stable quality can not only improve the credibility of products, but also reduce the pressure and cost of after-sales service. This is a huge hidden benefit for enterprises. Moreover, reliable quality products are more likely to gain the trust of customers, and in the long run, they can consolidate the market position of enterprises.

In addition, fibc sewing machines also have the characteristics of humanized design, which makes operation easier. Modern big bag sewing machine are usually equipped with electronic control systems and human-machine interfaces, and operators can set parameters and operate them simply through the touch screen. This design not only reduces the complexity of operation, but also reduces the high requirements for the technical level of operators and reduces training costs. Easy operation means that the conversion of production lines is more flexible, and enterprises can quickly adjust product types and specifications according to market demand, so as to better respond to market changes. More importantly, humanized design can effectively reduce operator fatigue, improve work efficiency and operational safety.

Finally, the versatility of fibc sewing machines is also an advantage that cannot be ignored. These machines usually have a modular design and can be adjusted and configured according to different production needs. For example, different types of sewing needles and sewing threads can be added, or additional functions such as cutting and pressing can be added. The versatility enables fibc sewing machines to meet the customized needs of various customers and perform well in handling container bags of different materials and specifications. In addition, the modular design also makes maintenance and upgrading more convenient. Enterprises can quickly adjust equipment according to production needs, reduce downtime and improve equipment utilization.

From hardware to software, the progress of modern sewing machinery technology shows the importance and irreplaceability of this professional equipment. These machines not only need to cope with the precise sewing of multi-layer composite materials, but also need to have automated and intelligent operation capabilities to adapt to various production environments and needs. At present, a number of high-end fiber container bag sewing machine brands have emerged in the market, competing to provide more intelligent solutions, such as real-time monitoring, fault detection and remote operation, so that operators can more easily control these behemoths. In addition, the flexibility and versatility of these super-large sewing machines enable them to play a role not only on factory assembly lines, but also to be used to make a variety of commercial, household and personalized products.

Looking at the world, the application scope of these high-tech sewing machines has expanded from traditional industrial fields to more diversified market demands, promoting the transformation and upgrading of the entire manufacturing industry. With the continuous advancement of technology and further optimization of software algorithms, we can foresee that FIBC sewing machines will achieve more breakthroughs in the future, further improving production efficiency and product standardization. In short, fiber container bag sewing machines, giant bag sewing machines, super large sewing machines and extra large sewing machine trolley bag sewing machines and other equipment are leading the new trend of the entire sewing industry with their excellent performance and wide range of application scenarios, and contributing indelibly to the improvement of global logistics levels and the improvement of quality of life.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025