which machine is used for doing chain stitch

Understanding the Chain Stitch Machine

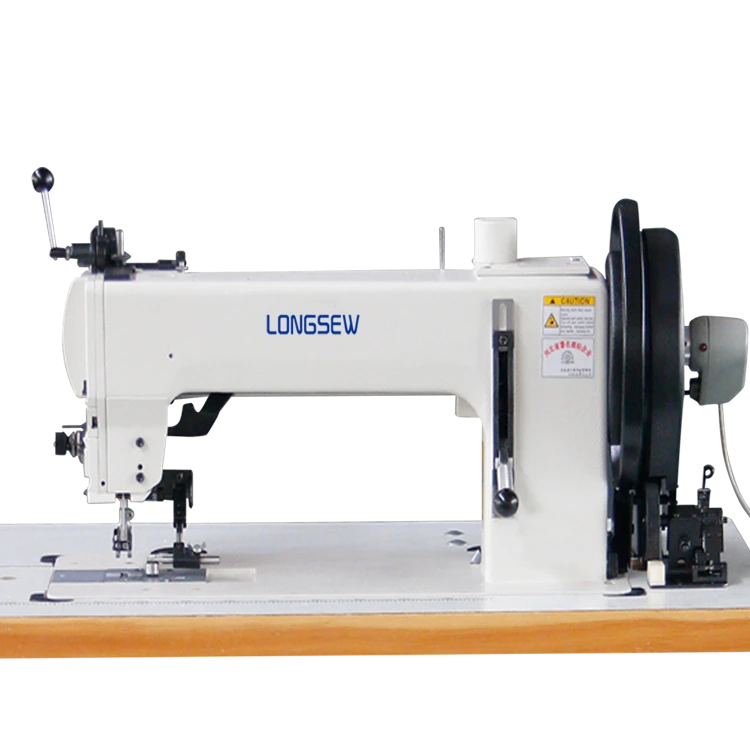

Chain stitching is a popular sewing technique that has been widely used in various textile industries due to its unique properties and applications. To execute chain stitches effectively, specific machines are employed, namely the chain stitch sewing machine. This machine has become invaluable in sectors where speed, flexibility, and durability are essential. In this article, we will explore the types of machines used for chain stitching, their mechanisms, applications, and advantages.

Types of Chain Stitch Machines

Chain stitch machines come in various forms, each designed for specific tasks within the sewing process. Two of the most common types include

1. Single Needle Chain Stitch Machine This type is the most commonly used machine for basic chain stitching. It employs a single needle that creates a looped stitch pattern. Generally, these machines are ideal for light to medium-weight fabrics. They are known for their simplicity and ease of use, making them popular in garment production and craftwork.

2. Double Needle Chain Stitch Machine This machine features two needles operating simultaneously, allowing the creation of parallel chain stitches. It's particularly useful for decorative purposes and providing a professional finish on garments. These machines often cater to the sewing of heavier fabrics and are more intricate in design compared to their single needle counterparts.

3. Overlock Machines with Chain Stitch Capability Overlock machines are crucial in seam finishing, and many modern models come equipped with the ability to perform chain stitching. This dual functionality allows for efficient production by combining seam finishing and stitching in one operation.

4. Specialized Industrial Machines In the realm of mass production, specialized industrial chain stitch machines are designed for high-speed operations. These machines can handle various fabrics and are commonly found in factories that produce a significant volume of clothing.

Mechanism of Action

which machine is used for doing chain stitch

The chain stitch machine operates using a unique mechanism involving a needle and a looper. The needle penetrates the fabric and creates a loop with the thread, which is then caught by a looper. This action forms a series of interlinked stitches, which are particularly elastic and durable. The design of these machines allows for quick stitching, leading to faster production times.

Applications of Chain Stitching

Chain stitching is widely used in several applications, especially in the garment industry. Its primary uses include

- Seaming and Hemming Chain stitches are employed for seams that require elasticity, such as knitwear and activewear, enabling garments to stretch and move comfortably. - Decorative Stitches The aesthetic quality of the chain stitch makes it suitable for decorative stitching on various textiles, enhancing the appeal of garments and accessories. - Quilting and Craft Work Quilters and artisans utilize chain stitch machines to create intricate designs and textures in their work. The characteristic look of chain stitches adds a unique touch to handmade items.

Advantages of Chain Stitching

The advantages offered by chain stitching are numerous

- Speed Chain stitch machines operate at high speeds, thus significantly reducing the time required for sewing. - Flexibility The chain stitch allows for a degree of stretch, making it ideal for fitted garments that require ease of movement. - Durability The constructive nature of chain stitches makes them resistant to fraying and unraveling, ensuring longevity in garments and textiles. - Cost-Effective In a mass production setting, chain stitch machines often lead to reduced labor costs and increased efficiency.

Conclusion

In summary, the chain stitch sewing machine plays an integral role in the textile and garment industries. Whether used for basic seaming, decorative applications, or garment finishing, these machines provide essential features that meet the demands of modern manufacturing. The evolution of chain stitch machines continues to enhance their capabilities, making them an essential tool for seamstresses and manufacturers alike. As technology advances, we can anticipate even greater innovations in the realm of chain stitching, further solidifying its importance in sewing practices worldwide.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025