Understanding the Functionality and Benefits of Lock Stitch Sewing Machines

Understanding the Lock Stitch Machine A Key Player in the Sewing Industry

The lock stitch machine is an essential tool in the textile and garment industry, known for its efficiency, durability, and versatility. This type of sewing machine has been a staple since its invention in the 19th century and continues to be the preferred choice for both amateur and professional sewers alike. In this article, we will delve into the mechanics, advantages, and applications of the lock stitch machine.

What is a Lock Stitch?

A lock stitch is a type of stitch formed by two threads the upper thread and the lower thread, which interlock with one another through a series of loops. The upper thread is fed from a spool located on top of the sewing machine, while the lower thread is drawn from a bobbin housed beneath the needle plate. As the needle penetrates the fabric, it carries the upper thread down and wraps it around the lower thread to create a secure stitch. This interlocking mechanism is what gives the lock stitch its strength and durability.

The Mechanics of a Lock Stitch Machine

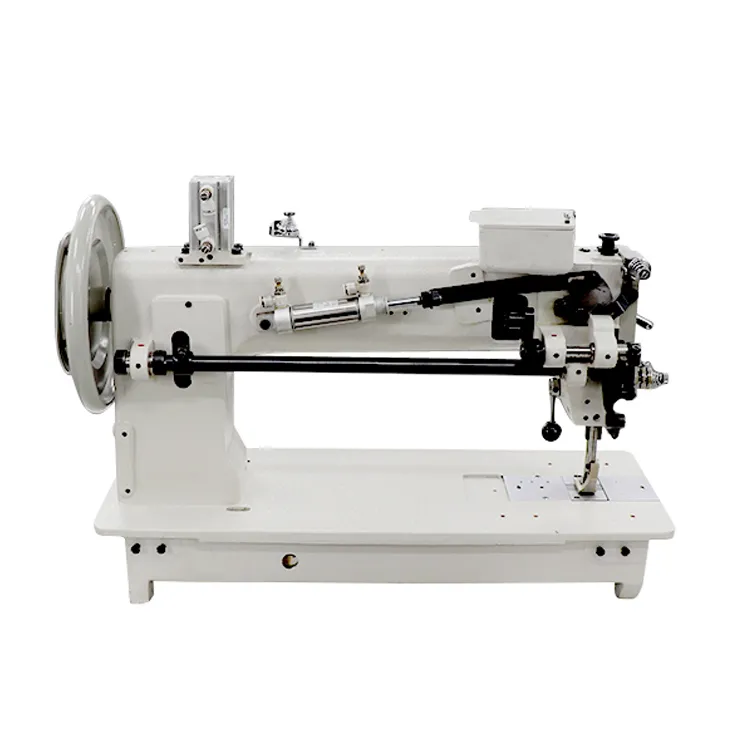

The lock stitch machine operates through a straightforward yet effective mechanism. When the user presses the foot pedal or pushes a button, the machine's motor engages, causing the needle to move up and down rapidly. As it moves down, the needle pierces the fabric and pulls the upper thread down through the material. At the same time, a hook mechanism, located underneath the needle plate, rotates and catches the upper thread, wrapping it around the lower thread to create a stitch.

Most modern lock stitch machines are designed to handle various fabric types, from lightweight materials like cotton and silk to heavier fabrics like denim and leather. They come equipped with various features such as adjustable stitch length and width, needle position adjustment, and even automatic thread-cutting capabilities.

Advantages of the Lock Stitch Machine

what is lock stitch machine

One of the most significant advantages of the lock stitch machine is its ability to produce strong and precise stitches. This makes it ideal for various sewing applications, including garment construction, quilting, and home décor projects. The lock stitch is less likely to unravel compared to other stitch types, ensuring the durability of the finished product.

Furthermore, lock stitch machines are generally easy to use, making them suitable for both novices and experienced sewers. The availability of computerized models has also made it easier to manage complex projects with specific design requirements, including embroidery and decorative stitching.

Applications in the Industry

Lock stitch machines have a wide range of applications in the garment and textile industry. They are commonly used in clothing manufacturing for sewing seams, hems, and attaching embellishments. Additionally, they are pivotal in the creation of home goods, such as curtains, upholstery, and bedding.

Beyond commercial use, lock stitch machines are popular in home sewing. They offer a reliable solution for hobbyists and crafters who wish to create their unique clothing, accessories, or gifts. With the advent of online tutorials and sewing patterns, many individuals have embraced the lock stitch machine to express their creativity.

Conclusion

In summary, the lock stitch machine is a vital component of the sewing industry, offering unmatched strength, versatility, and ease of use. Whether you are an industry professional or a home sewing enthusiast, understanding the function and benefits of the lock stitch machine can enhance your sewing experience. As technology continues to evolve, these machines will likely incorporate even more features, making them more efficient and user-friendly, while still maintaining their fundamental ability to produce strong and durable stitches. Whether in a professional workshop or a cozy home setup, the lock stitch machine truly stands out as an indispensable tool for anyone who sews.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025