Jan . 14, 2025 12:30

Back to list

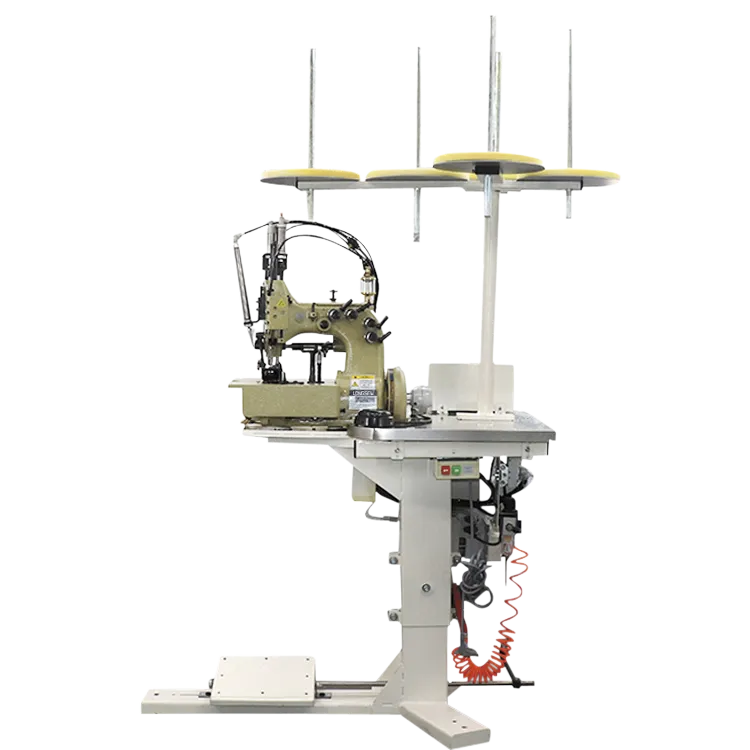

what is a lock stitch on a sewing machine

Lock stitch is a fundamental component of sewing machines, offering reliability and versatility, which are crucial for both beginners and seasoned sewers. At its core, a lock stitch forms by interlocking two threads, typically an upper and a lower thread, to create a secure seam. This type of stitch is renowned for its durability and clean finish, making it indispensable for a variety of sewing projects, whether for garments, upholstery, or crafting.

Authoritativeness in using a lock stitch machine comes from mastering its settings and maintenance. Most modern machines allow for adjustable stitch lengths and widths, affording the user control over the final appearance of the stitch. Shorter stitch lengths provide a more robust seam, ideal for reinforced stitching in high-stress areas, whereas longer stitches might be employed for basting or decorative topstitching. Moreover, regular cleaning and oiling of the machine’s internal components ensure consistent performance and longevity, an essential practice for maintaining the machine's operability at an expert level. Trustworthiness in employing lock stitch techniques also involves recognizing the machine's limitations and compensating accordingly. Although highly effective, lock stitches can occasionally unravel at the seam ends if not properly secured, prompting the use of reverse stitching at the start and end points. Additionally, sewists should be vigilant about needle selection, opting for the correct type and size based on the fabric to prevent skipped stitches or fabric damage, which could compromise the integrity of the project. In sum, the lock stitch remains a cornerstone of sewing, valued for its strength, versatility, and precision. By harnessing the technique with an informed and methodical approach, sewists can not only ensure the quality and professionalism of their work but also extend the utility and lifespan of their sewing machines. This symbiotic relationship between skill and technology underscores the lock stitch's enduring relevance in the fabric arts, fostering creativity and innovation while upholding traditional sewing standards.

Authoritativeness in using a lock stitch machine comes from mastering its settings and maintenance. Most modern machines allow for adjustable stitch lengths and widths, affording the user control over the final appearance of the stitch. Shorter stitch lengths provide a more robust seam, ideal for reinforced stitching in high-stress areas, whereas longer stitches might be employed for basting or decorative topstitching. Moreover, regular cleaning and oiling of the machine’s internal components ensure consistent performance and longevity, an essential practice for maintaining the machine's operability at an expert level. Trustworthiness in employing lock stitch techniques also involves recognizing the machine's limitations and compensating accordingly. Although highly effective, lock stitches can occasionally unravel at the seam ends if not properly secured, prompting the use of reverse stitching at the start and end points. Additionally, sewists should be vigilant about needle selection, opting for the correct type and size based on the fabric to prevent skipped stitches or fabric damage, which could compromise the integrity of the project. In sum, the lock stitch remains a cornerstone of sewing, valued for its strength, versatility, and precision. By harnessing the technique with an informed and methodical approach, sewists can not only ensure the quality and professionalism of their work but also extend the utility and lifespan of their sewing machines. This symbiotic relationship between skill and technology underscores the lock stitch's enduring relevance in the fabric arts, fostering creativity and innovation while upholding traditional sewing standards.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025