Jan . 20, 2025 02:33

Back to list

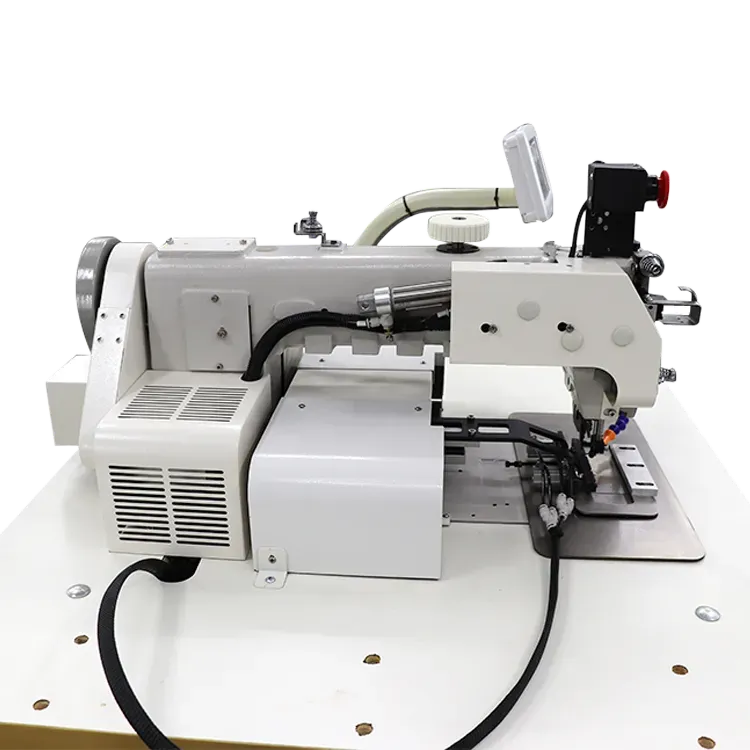

double needle lock stitch sewing machine

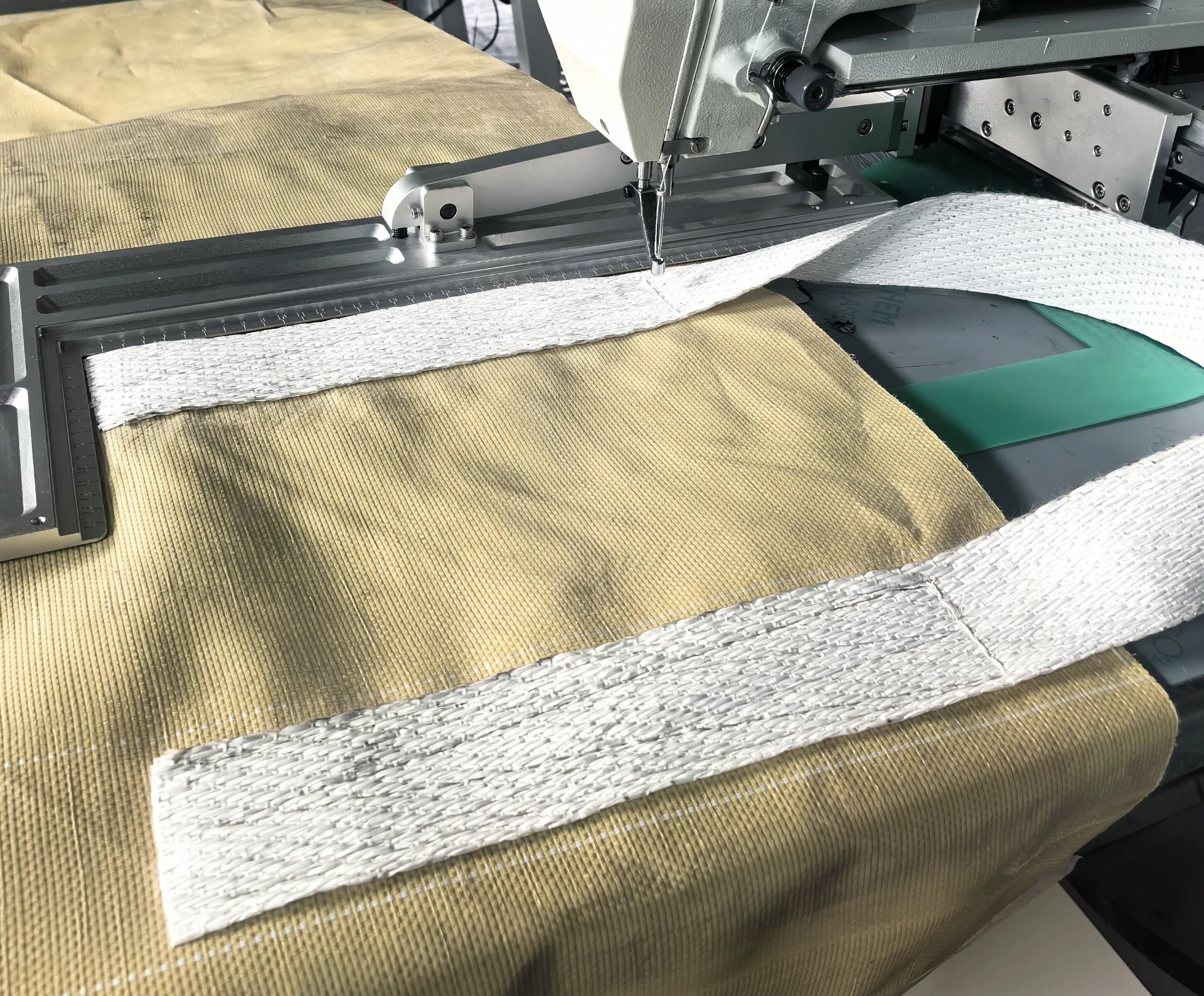

A lock stitch machine is a fundamental tool in garment construction and textile industries, renowned for creating strong, reliable seams. This machine operates with a needle and a bobbin thread, intertwining them to form a secure stitch. Its name is derived from the interlocking mechanism that keeps fabric pieces firmly sewn together, proving its versatility in various applications from fashion to upholstery.

Lock stitch machines are also equipped with various technological advances that heighten their efficiency and user-friendliness. Modern machines often integrate automation capabilities, such as programmable stitch patterns and automatic tension adjustment, supporting consistent and precise production. These features benefit large-scale manufacturers and individual craftspeople by reducing the potential for human error and fatigue associated with manual sewing. Maintenance and trustworthiness of a lock stitch machine are vital to long-term productivity. Routine cleaning, proper lubrication, and timely servicing ensure consistent performance while extending the life of the machine. Manufacturers usually provide detailed maintenance guidelines, emphasizing the importance of adhering to their recommendations to preserve machine-quality output. Authoritatively, the reliability of a lock stitch machine extends beyond its mechanical design into the realm of skill development. Mastering this machine equips users with a critical skill set appreciated across numerous textile-based industries. Educational programs and sewing workshops consistently incorporate lock stitch machine training, recognizing its value in developing both professional and hobbyist sewing expertise. In conclusion, whether for industrial uses or personal crafting projects, the lock stitch machine is a staple of sewing technology. Its historical significance, technical precision, and capacity for producing sturdy, clean seams make it indispensable. Investing time in understanding its mechanism, maintenance, and applications not only enhances sewing quality but also empowers users with a deeper appreciation for one of the industry's most enduring tools.

Lock stitch machines are also equipped with various technological advances that heighten their efficiency and user-friendliness. Modern machines often integrate automation capabilities, such as programmable stitch patterns and automatic tension adjustment, supporting consistent and precise production. These features benefit large-scale manufacturers and individual craftspeople by reducing the potential for human error and fatigue associated with manual sewing. Maintenance and trustworthiness of a lock stitch machine are vital to long-term productivity. Routine cleaning, proper lubrication, and timely servicing ensure consistent performance while extending the life of the machine. Manufacturers usually provide detailed maintenance guidelines, emphasizing the importance of adhering to their recommendations to preserve machine-quality output. Authoritatively, the reliability of a lock stitch machine extends beyond its mechanical design into the realm of skill development. Mastering this machine equips users with a critical skill set appreciated across numerous textile-based industries. Educational programs and sewing workshops consistently incorporate lock stitch machine training, recognizing its value in developing both professional and hobbyist sewing expertise. In conclusion, whether for industrial uses or personal crafting projects, the lock stitch machine is a staple of sewing technology. Its historical significance, technical precision, and capacity for producing sturdy, clean seams make it indispensable. Investing time in understanding its mechanism, maintenance, and applications not only enhances sewing quality but also empowers users with a deeper appreciation for one of the industry's most enduring tools.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025