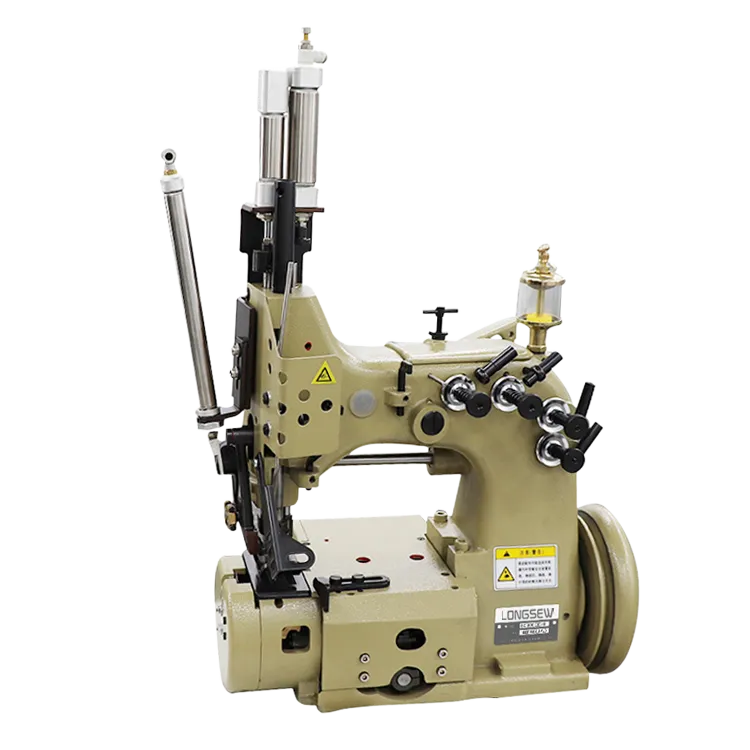

upholstery binding machine

Exploring the Upholstery Binding Machine A Key Player in Textile Crafting

Upholstery binding machines are essential tools in the realm of textile crafting and furniture manufacturing. These specialized machines play a critical role in the finishing process, ensuring that upholstery projects have a professional and polished appearance. In this article, we will explore the functions, benefits, and significance of upholstery binding machines, highlighting why they are indispensable for both amateur crafters and seasoned professionals.

At the core of their functionality, upholstery binding machines are designed to attach binding materials, such as fabric, leather, or vinyl, to the edges of upholstery items. This process not only enhances the aesthetic appeal of the final product but also provides protection to the raw edges of the fabric. By covering these seams, the binding adds durability and increases the lifespan of the upholstery, making it a worthwhile investment for any project.

One of the key advantages of using an upholstery binding machine is the efficiency it brings to the production process. Traditional methods of binding often require significant manual labor, which can be both time-consuming and prone to error. In contrast, a binding machine automates many of these tasks, reducing the time needed to complete upholstery projects. This efficiency allows craftsmen to take on larger projects or produce items at a faster rate, ultimately leading to increased profitability.

upholstery binding machine

Moreover, upholstery binding machines come equipped with a variety of features designed to enhance versatility and ease of use. Many machines offer adjustable settings for different binding widths and types, accommodating a wide range of materials and styles. This adaptability allows users to tackle various projects, from simple cushions to intricate furniture pieces, without needing multiple machines.

In addition to their functionality, modern upholstery binding machines are engineered with user-friendly interfaces. Many models feature intuitive controls and digital displays, making it easier for operators of all skill levels to achieve professional results. This accessibility has made upholstery binding machines more appealing to hobbyists and small business owners who may not have extensive experience with industrial machinery.

The importance of upholstery binding machines extends beyond individual projects; they play a significant role in the broader furniture and textile industry. With the growing emphasis on quality and craftsmanship, the demand for well-finished products has increased. Upholstery binding machines contribute to this demand by ensuring that every piece meets high standards of quality, thereby enhancing overall consumer satisfaction.

In conclusion, upholstery binding machines are vital instruments in the textile crafting world. They not only improve the efficiency and quality of upholstery projects but also provide artisans with the versatility and ease required to innovate and excel in their craft. Whether for personal projects or professional production, the upholstery binding machine paves the way for creating beautiful, durable, and market-ready items, solidifying its place as a key player in the industry. As technology advances, we can expect these machines to evolve further, offering even more features and capabilities to meet the diverse needs of today's crafters.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025