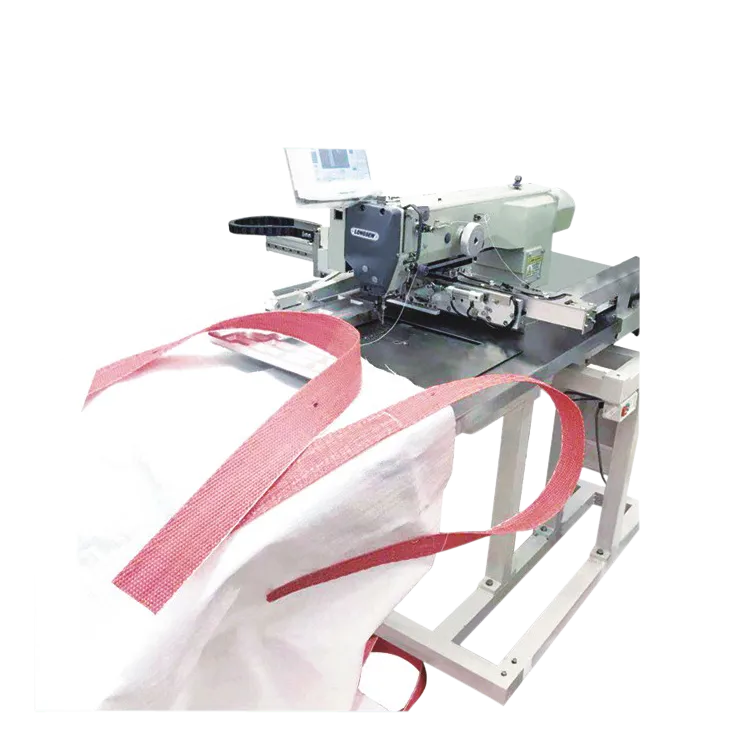

union lockstitch sewing machine

The Union Lockstitch Sewing Machine A Revolution in Textile Manufacturing

The world of textile production has undergone significant transformations over the past century, and one of the most crucial innovations that have led to such advancements is the Union lockstitch sewing machine. This remarkable piece of equipment has revolutionized sewing processes, ensuring precision, efficiency, and durability in garment manufacturing. Understanding the Union lockstitch sewing machine's history, functionality, and impact can provide valuable insights into its role in shaping the textile industry today.

Historical Background

The Union lockstitch sewing machine emerged during the Industrial Revolution, a period marked by rapid technological advancement and mass production. The Union Manufacturing Company, founded in the late 19th century, was one of the pioneers in creating reliable sewing machines that met the growing demands of the apparel industry. Their introduction of the lockstitch mechanism allowed for a robust and secure stitch that would not easily unravel, a significant improvement over previous models that often used simpler stitching methods.

Mechanism and Functionality

At its core, the Union lockstitch sewing machine operates on a straightforward yet effective mechanism. It uses two threads—a top thread and a bottom thread—forming a stitch by locking together through the fabric layers. The top thread is fed through a needle, while the bottom thread is drawn from a bobbin located beneath the sewing plate. The intertwining of these two threads creates a strong seam that is both durable and aesthetically pleasing, making it particularly suitable for various types of fabrics, from lightweight materials to heavier ones.

One of the standout features of the Union lockstitch sewing machine is its ability to produce consistent stitch quality across different fabric types. This uniformity is essential for garment manufacturing, where precision is paramount. Moreover, the machine is designed for versatility, allowing operators to make adjustments for different stitch lengths and widths, catering to diverse sewing requirements.

Impact on the Textile Industry

union lockstitch sewing machine

The introduction of the Union lockstitch sewing machine marked a turning point in the textile manufacturing landscape. Before its popularization, sewing was predominantly a manual task, requiring significant time and effort. With the Union machine, manufacturers could significantly increase their production rates, which aligned perfectly with the rising demand for ready-to-wear clothing in the early 20th century.

The efficiency of the Union lockstitch sewing machine also had economic implications. By streamlining the production process, textile manufacturers could lower their operational costs, reduce lead times, and ultimately provide more affordable clothing options to consumers. This accessibility played a crucial role in the democratization of fashion, allowing a broader segment of the population to purchase high-quality garments.

Modern Applications and Advances

While the basic principles of the Union lockstitch sewing machine remain largely unchanged, modern advancements have enhanced its functionality. Today's machines come equipped with computerized systems that allow for greater precision and automation. Features such as automatic thread trimming, on-screen sewing adjustments, and programmable stitch patterns have transformed the sewing experience, making it more user-friendly and efficient.

Moreover, environmental sustainability has become a pressing concern in the textile industry. The newer models of Union lockstitch sewing machines are designed to minimize waste by optimizing thread usage and reducing energy consumption, addressing the industry's ecological footprint.

Conclusion

In summary, the Union lockstitch sewing machine represents a critical advancement in the history of textile manufacturing. Its innovative design and efficient operation have transformed sewing from a labor-intensive task into an automated process that increases productivity and maintains high-quality standards. As the textile industry continues to evolve, the principles behind the Union lockstitch sewing machine remain relevant, serving as a testament to the enduring importance of this remarkable invention in fashion and garment production. Moving forward, this machine will likely continue to play a vital role in shaping the future of textile manufacturing, balancing tradition with modernization and sustainability.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025