Exploring the Versatility of Twin Needle Industrial Sewing Machines for Quality Stitching

The Twin Needle Industrial Sewing Machine An Essential Tool for Modern Textiles

In the fast-evolving world of textiles and garment manufacturing, the twin needle industrial sewing machine stands out as a significant piece of equipment, combining efficiency and versatility in one compact unit. This machine, which employs two needles simultaneously, is widely used in the production of various fabric types, offering a range of applications from decorative stitching to functional seams.

Understanding the Twin Needle Functionality

At its core, a twin needle sewing machine operates by threading two needles through a single piece of fabric. This allows for the creation of parallel stitching lines, which can be both aesthetically pleasing and structurally sound. The machine uses two bobbins or a specialized thread guide that enables both needles to pull from a single thread supply. The effect is not only visually appealing, creating double-stitched seams that resemble the appearance of serging, but it also enhances the strength and durability of the seam.

Applications in Modern Apparel Production

The twin needle sewing machine is a staple in the garment industry, particularly in the production of knitwear, activewear, and other stretchable fabrics. With its ability to create two lines of stitches, it is particularly effective for hems and elastic bands, where flexibility and durability are crucial. It can also be used to finish edges, provide decorative patterns, and reinforce seams, ensuring that garments can withstand the rigors of everyday wear.

For manufacturers, the speed and efficiency of twin needle machines make them an invaluable investment. They can significantly reduce production time compared to traditional single-needle machines, allowing for higher throughput without sacrificing quality. Many advanced models come equipped with features such as automatic thread tension control, programmable stitch lengths, and even digital adjustments, making them user-friendly and efficient for various applications.

Advantages Over Traditional Sewing Machines

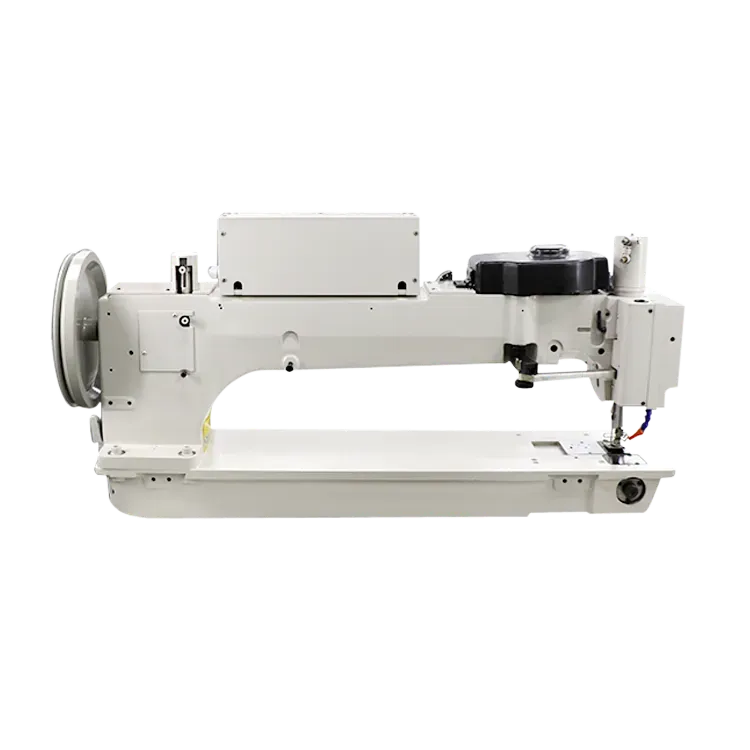

twin needle industrial sewing machine

While traditional sewing machines are versatile and have been a mainstay in sewing workshops for decades, twin needle machines offer distinct advantages for commercial operations. One of the most notable benefits is the reduced time taken to achieve a finished product. With the capability to sew two lines of stitching simultaneously, there is less need for multiple passes over the fabric, thereby speeding up the production process.

Additionally, the twin needle sewing machine produces a more polished appearance, which is increasingly important in today’s fashion-forward market. Consumers are often drawn to garments that feature refined and professional-looking seams, and the twin needle offers a way to achieve this with ease.

Another significant advantage is the machine's adaptability. It can be used with various stitch types and fabric weights, giving manufacturers the flexibility to produce a wide range of products—from delicate blouses to robust outdoor apparel.

Challenges and Considerations

Despite its many advantages, using a twin needle industrial sewing machine is not without its challenges. Proper threading and tension adjustments are crucial to ensure that both needles perform optimally. Additionally, operators must be trained to understand the nuances of using this specialized machine to prevent common issues such as skipped stitches or thread breakage.

Maintenance is another critical consideration; regular servicing is essential to keep the machine running smoothly and to prevent costly downtime during production.

Conclusion

The twin needle industrial sewing machine represents a convergence of technology and practicality, addressing the demands of modern textile manufacturing with finesse. Its ability to combine efficiency with quality makes it an indispensable tool in the apparel industry. As manufacturers continue to seek ways to innovate and streamline production, the twin needle machine will undoubtedly remain at the forefront, transforming the way we think about sewing and garment construction. For both seasoned professionals and newcomers to the industry, understanding this remarkable machine is key to mastering the art of textile production in the 21st century.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025