ton bag sewing machine

The Versatility of Ton Bag Sewing Machines

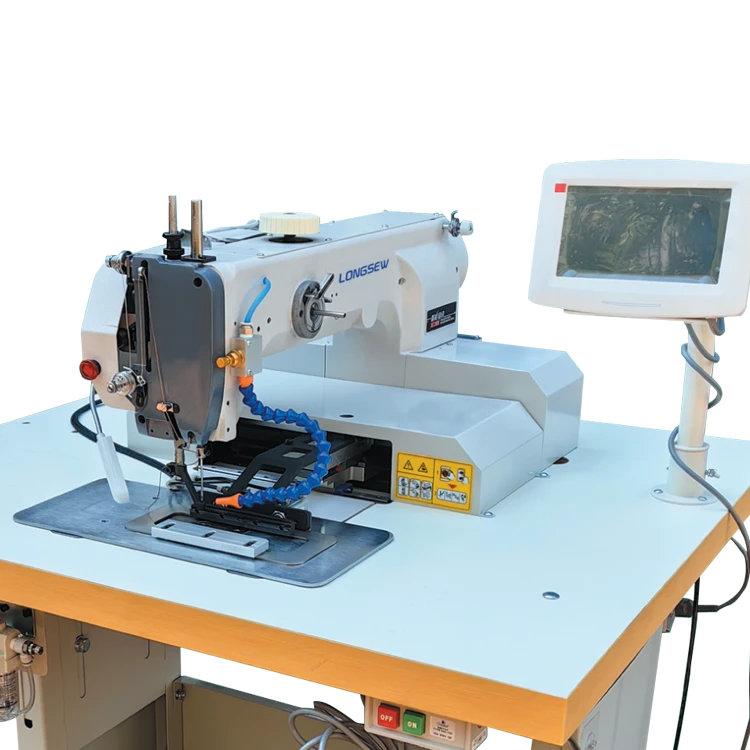

In the world of textiles and manufacturing, the ton bag sewing machine stands out as a vital piece of equipment. These machines are specifically designed for sewing heavy-duty fabrics, primarily used in the production of ton bags, also referred to as bulk bags or FIBC (Flexible Intermediate Bulk Containers). Ton bags are crucial for the safe and efficient transport of various materials, ranging from agricultural products to construction materials.

Importance of Ton Bags

Ton bags play a significant role in several industries due to their ability to hold large quantities of materials—often up to a ton or more. They are made from durable polypropylene fabric, which is not only lightweight but also resistant to moisture and UV rays. The versatility and strength of these bags make them a popular choice for businesses that require safe and efficient packaging solutions. Since ton bags can be reused and recycled, they also align with environmentally-friendly practices that are increasingly being adopted by companies worldwide.

Features of Ton Bag Sewing Machines

Ton bag sewing machines are designed with heavy-duty components to handle the thick, multi-layered fabrics used in ton bag production. Unlike standard sewing machines, these specialized machines can sew through multiple layers of fabric and are equipped with powerful motors that can generate high levels of torque. This capacity allows for fast stitching speeds, reducing production time and increasing efficiency.

Additionally, ton bag sewing machines often come with features that enhance their usability - Adjustable Stitch Width This allows manufacturers to customize stitching specifications based on the type of ton bag being produced. - Automatic Thread Trimmers These reduce the need for manual cutting, streamlining the production process. - Robust Presser Feet Designed to handle heavy materials without slipping, ensuring consistent, high-quality stitches.

ton bag sewing machine

Applications and Benefits

The applications of ton bag sewing machines extend beyond just the textile industry. They are used in agriculture, construction, chemical manufacturing, and even food processing. Businesses in these sectors appreciate the benefits of ton bags, such as their lightweight design, ease of transport, and cost-effectiveness.

Moreover, companies that operate on a large scale require efficient production processes. Ton bag sewing machines enable manufacturers to increase their output while maintaining high standards of quality. The durability of the bags produced ensures that they can withstand the rigors of transportation and handling, significantly reducing the risk of product loss or damage.

Conclusion

In conclusion, ton bag sewing machines are an essential tool in the production of ton bags, which serve a critical function across various industries. Their unique features and capabilities enable manufacturers to produce high-quality products efficiently. As the demand for ton bags continues to grow, driven by their adaptability and sustainability, investing in advanced ton bag sewing machinery becomes increasingly important for competitive businesses.

With advancements in technology, we can expect future developments in ton bag sewing machines that enhance their efficiency, reduce waste, and further support the industry's shift toward sustainable practices. Whether you are a small business or a large enterprise, embracing the capabilities of ton bag sewing machines can lead to innovation and growth in today's dynamic market.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025