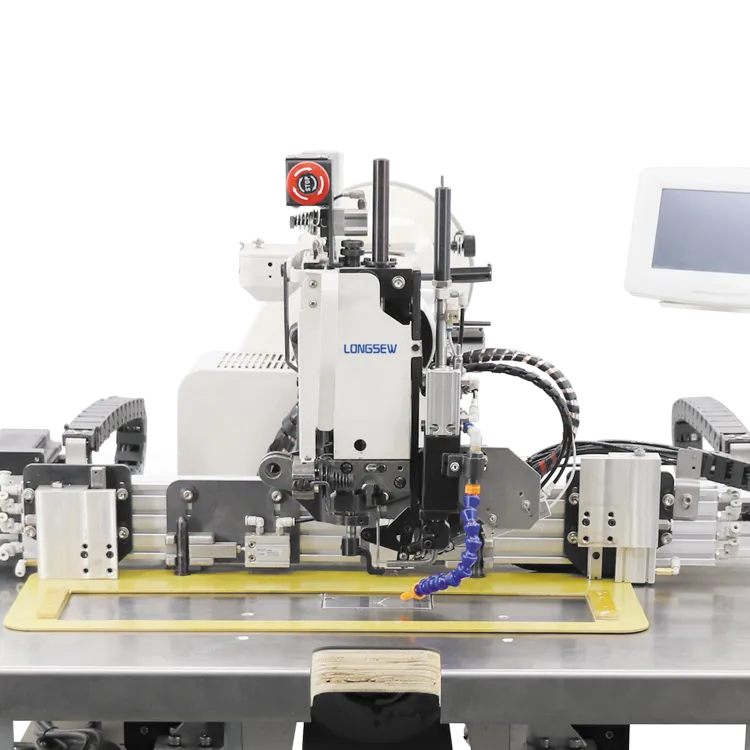

straight and zigzag industrial sewing machine

The Importance of Straight and Zigzag Industrial Sewing Machines in Modern Manufacturing

Industrial sewing machines play an integral role in the manufacturing landscape, particularly in the textile and apparel industries. Among the various types of sewing machines available, straight and zigzag machines are two of the most fundamental tools that every manufacturer should consider. Each type serves distinct purposes and offers unique advantages that can greatly enhance production efficiency and the quality of finished products.

Straight sewing machines are designed primarily for making straight seams, which is the most basic and common stitch used in sewing. These machines are renowned for their speed and precision, allowing factories to produce large volumes of garments quickly without compromising quality. The simplicity of their design means they are user-friendly and require minimal training to operate effectively. Additionally, straight sewing machines excel in creating durable seams that can withstand the wear and tear of everyday use, making them ideal for manufacturing items like denim jeans and workwear.

On the other hand, zigzag sewing machines offer more versatility than their straight-stitch counterparts. These machines can create a variety of stitch patterns, including zigzag, which allows them to be used in decorative stitching, finishing edges, and providing stretch in seams. This flexibility is particularly valuable in the production of garments made from knit fabrics, where a straight stitch might break under tension. The zigzag stitch can also be used for appliqué work, quilting, and repairing fabrics, making these machines essential for both mass production and smaller custom projects.

straight and zigzag industrial sewing machine

Moreover, the integration of both straight and zigzag sewing machines in a production line can significantly streamline the manufacturing process. By utilizing both types of machines, manufacturers can optimize workflow, ensuring that different sewing tasks are assigned to the most suitable machine. This not only improves efficiency but also maintains high standards of quality control across various types of seams and constructions.

As technology continues to evolve, modern straight and zigzag sewing machines are being equipped with advanced features such as automatic threading, programmable stitch patterns, and enhanced speed control

. These innovations are designed to meet the growing demands of the industry's competitive landscape, allowing manufacturers to produce high-quality products more efficiently than ever before.In conclusion, straight and zigzag industrial sewing machines are indispensable tools in the textile industry. Their unique features and abilities cater to various sewing needs, making them vital for quality production. As the industry evolves, the importance of these machines will only continue to grow, reinforcing their role as the backbone of modern garment manufacturing. Investing in both types of machines will allow manufacturers to maximize productivity and maintain a competitive edge in a fast-paced market.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025