Feb . 14, 2025 07:23

Back to list

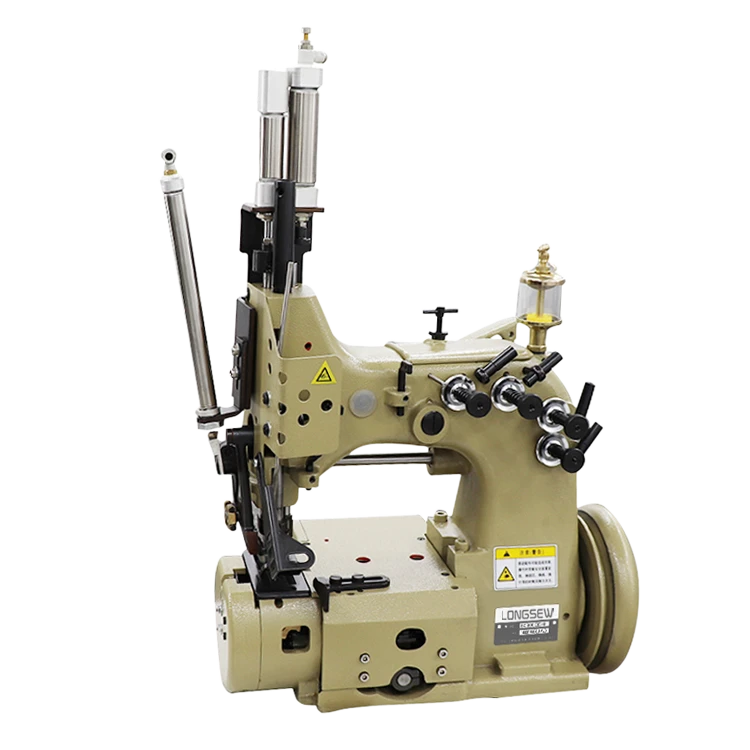

stitching thick leather

Stitching thick leather can present unique challenges, yet it can be extremely rewarding for anyone involved in leatherworking. When dealing with such a robust material, the right techniques and tools are essential for achieving the best results. This article delves into the specifics of what it takes to master the art of stitching thick leather, offering insights drawn from years of experience and professional expertise.

The workspace environment also factors into the successful stitching of thick leather. Having a well-lit and organized work area minimizes mistakes and promotes efficiency. Keeping your tools within easy reach and regularly maintained ensures smoother operations. Ensuring adequate ventilation is also beneficial, particularly when working with treatments or finishes that may release fumes. Incorporating moisture into the leather can aid in ease of stitching. Damping the leather softens it, making it more pliable and easier to manipulate, allowing the needle and thread to pass more effortlessly. However, this must be done cautiously, as excessive moisture can distort the leather. Personal experience plays a vital role in leatherworking. Mastery comes from practice and learning from each project. Beginning with smaller projects can build confidence and understanding of how thick leather behaves during stitching. Sharing experiences with a community of leatherworkers can also provide new techniques and insights. Ultimately, achieving excellence in stitching thick leather relies on balancing patience with practice, guided by the right tools and techniques. As you continue to develop your craft, you'll find that each stitched piece becomes a testament to your growing skill and dedication. By exploring traditional methods while remaining open to new solutions, craftspersons can create beautiful, durable leather goods that stand the test of time.

The workspace environment also factors into the successful stitching of thick leather. Having a well-lit and organized work area minimizes mistakes and promotes efficiency. Keeping your tools within easy reach and regularly maintained ensures smoother operations. Ensuring adequate ventilation is also beneficial, particularly when working with treatments or finishes that may release fumes. Incorporating moisture into the leather can aid in ease of stitching. Damping the leather softens it, making it more pliable and easier to manipulate, allowing the needle and thread to pass more effortlessly. However, this must be done cautiously, as excessive moisture can distort the leather. Personal experience plays a vital role in leatherworking. Mastery comes from practice and learning from each project. Beginning with smaller projects can build confidence and understanding of how thick leather behaves during stitching. Sharing experiences with a community of leatherworkers can also provide new techniques and insights. Ultimately, achieving excellence in stitching thick leather relies on balancing patience with practice, guided by the right tools and techniques. As you continue to develop your craft, you'll find that each stitched piece becomes a testament to your growing skill and dedication. By exploring traditional methods while remaining open to new solutions, craftspersons can create beautiful, durable leather goods that stand the test of time.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025