stitching automatic machine price

The Price of Stitching Automatic Machines A Comprehensive Overview

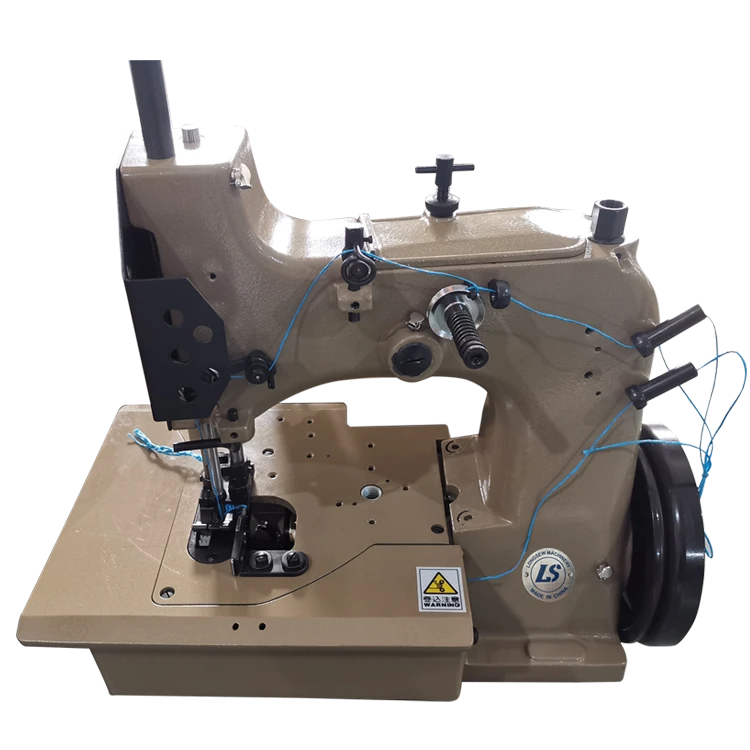

In today’s fast-paced production environments, stitching automatic machines have become indispensable tools for manufacturers in various industries, including textiles, automotive, and packaging. These machines not only enhance efficiency but also ensure consistent quality in stitching operations. However, one of the primary considerations when investing in such technology is the price. Understanding the factors that influence the pricing of stitching automatic machines can help businesses make informed purchasing decisions.

Understanding the Market

The market for stitching automatic machines is diverse, with numerous manufacturers offering a wide range of models. Prices can vary significantly based on several factors, including the type of machine, its features, brand reputation, and the level of automation. On the lower end, basic sewing machines suitable for small-scale operations can start as low as $1,000. Conversely, advanced, industrial-grade machines equipped with sophisticated technologies could cost anywhere from $10,000 to over $100,000.

Key Factors Influencing Price

1. Type of Machine The type of stitching machine plays a crucial role in determining its price. Basic sewing machines, coverstitch machines, and overlock machines tend to be less expensive than multi-function machines that perform various tasks such as embroidery, quilting, and tacking. Additionally, specialized machines designed for niche markets (like leather or heavy-duty textiles) often command higher prices due to their unique features and capabilities.

2. Automation Level The level of automation integrated into the machine significantly impacts its cost. Manual machines are typically the most budget-friendly options, while semi-automatic and fully automatic machines, which can significantly reduce labor costs and increase production speed, come at a premium. Machines featuring programmable settings, automatic threading, and advanced sensors for material handling will generally be priced higher.

3. Brand Reputation and After-Sales Support Established brands with a reputation for quality and reliability often price their machines higher than lesser-known brands. This premium reflects not only the machine's reliability but also the warranty and after-sales support provided. A good support system can be crucial for minimizing downtime in production, making it a worthwhile investment.

stitching automatic machine price

4. Features and Technology Advanced features such as computerization, interactive displays, and connectivity can increase a machine's price. Machines equipped with user-friendly interfaces, complete with touchscreens and software for design modifications, are more expensive due to their enhanced capabilities. Additionally, machines with energy-efficient technology may also come at a higher price but offer long-term cost savings through reduced energy consumption.

5. Market Trends and Economic Factors External factors, including global market trends and economic conditions, can also impact the pricing of stitching machines. For instance, fluctuations in raw material costs, changes in tariffs or import/export regulations, and shifts in demand can lead to price adjustments. Keeping an eye on these trends can help businesses anticipate price changes and negotiate better deals.

Evaluating Your Needs

When considering the purchase of a stitching automatic machine, it is essential to evaluate your specific needs and production requirements. Businesses should conduct a thorough assessment of their operations to determine the type of machine that best aligns with their goals. Factors such as production volume, material types, desired stitch quality, and projected growth should be taken into account.

The Long-Term Investment

While the upfront cost of stitching automatic machines can be daunting, it is crucial to view them as long-term investments. The efficiency gains, reduced labor costs, and improved product quality that these machines offer can lead to considerable savings over time. Additionally, financing options, leasing arrangements, and trade-in deals are often available, making it easier for businesses to access high-quality machinery without overextending their budgets.

Conclusion

Investing in a stitching automatic machine is a significant decision impacted by various factors that affect pricing. By understanding the market landscape, evaluating specific needs, and considering the long-term benefits, businesses can make informed choices that will enhance their productivity and competitiveness in the textile industry. As technology continues to evolve, staying updated on trends and innovations will further aid in maximizing the value of these essential machines.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025