Step-by-Step Guide to Threading a Single Needle Lockstitch Sewing Machine for Beginners

Mastering the Art of Threading a Single Needle Lockstitch Machine

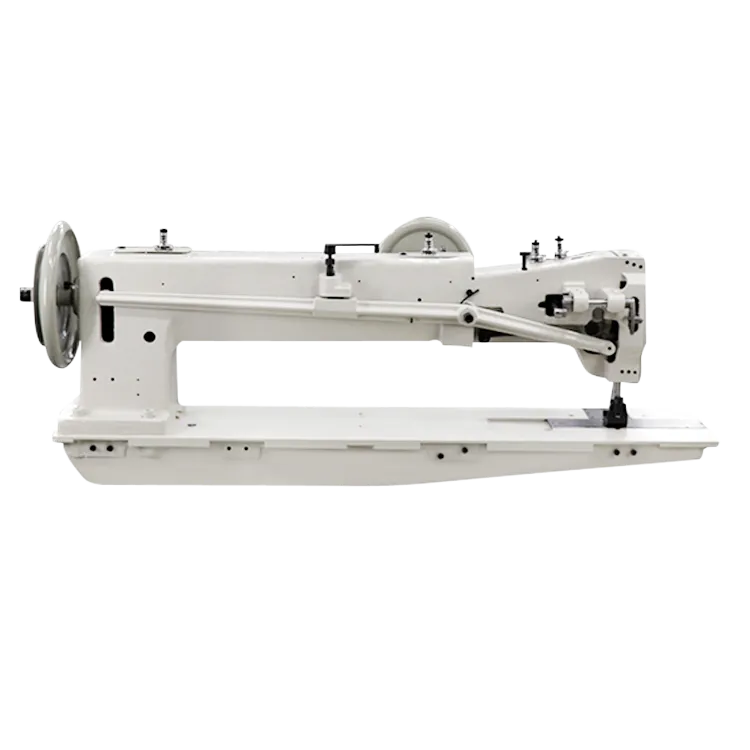

The single needle lockstitch machine is an essential tool in the world of garment manufacturing and tailoring, known for its versatility and capability to produce high-quality stitches. Proper threading of this machine is crucial not only for achieving a flawless finish but also for ensuring optimal sewing performance. This article will guide you through the steps and best practices for threading a single needle lockstitch machine effectively.

Understanding the Components

Before diving into the threading process, it's important to familiarize yourself with the machine's components. The single needle lockstitch machine typically consists of a spool holder, tension disks, a needle bar, a bobbin case, and a presser foot. Each part plays a vital role in the overall function of the machine. The spool holder holds the upper thread, while the needle bar is responsible for guiding the thread through the needle and into the fabric. Meanwhile, the bobbin case contains the lower thread, which interlocks with the upper thread to create stitches.

Step-by-Step Threading Process

1. Gather Your Materials Ensure you have your sewing machine, a spool of thread, a bobbin wound with thread, scissors, and a needle suitable for your fabric type.

2. Prepare the Machine Start by turning off the machine and raising the needle and presser foot. This will give you adequate access to the threading areas and prevent any accidents.

3. Thread the Upper Thread - Place your spool of thread on the spool holder. Make sure it is securely positioned to prevent tangling. - Pass the thread through the thread guides located on the upper part of the machine, typically marked with numbers for reference. - Pull the thread down toward the tension disks. It’s crucial to ensure the thread is placed between these disks. This step is critical for controlling stitch tension. - Continue threading the machine by guiding the thread through the take-up lever, then down toward the needle.

single needle lockstitch machine threading

4. Insert the Needle - Thread the needle from front to back, ensuring the thread is well seated. Depending on the machine, you may need to use a needle threader for convenience. - Pull a few inches of thread through the needle and let it hang.

5. Prepare the Bobbin - Insert the bobbin into the bobbin case with the thread winding in the correct direction. Typically, this is clockwise, but check your machine’s manual for specifics. - Pull the thread through the slot in the bobbin case and under the tension spring.

6. Engage the Bobbin Thread - Hold the upper thread while turning the handwheel towards you. This action should lower and then raise the needle, catching the bobbin thread. - Pull the bobbin thread up to the surface, allowing you to have both threads available to begin sewing.

7. Final Preparations - Ensure that both threads (upper and lower) are long enough to start sewing, ideally around 6-8 inches. - Lower the presser foot and make any necessary adjustments to the tension settings according to the fabric you are working with.

Tips for Successful Threading

- Consult the Manual Each machine may have specific threading instructions which might vary slightly. Always refer to the user manual for your specific model. - Use Quality Thread Low-quality thread can lead to tangling or breaking. Invest in good-quality thread for the best results. - Regular Maintenance Keep your machine clean and well-oiled to ensure efficient functioning and longevity.

In conclusion, mastering the threading process on a single needle lockstitch machine is a fundamental skill for anyone engaging in sewing activities. By following the outlined steps and tips, you can ensure smooth operation and high-quality stitching, resulting in professional-looking garments and projects. Happy sewing!

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025