Versatile Single Needle Lockstitch Sewing Machine for Precision and Efficiency in Tailoring

The Versatility and Importance of the Single Needle Lockstitch Machine

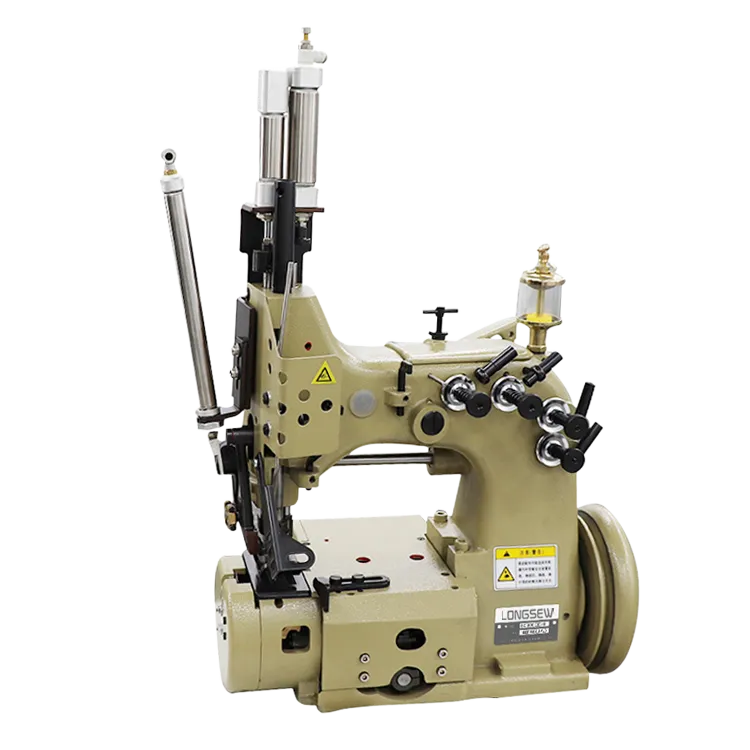

The single needle lockstitch machine is a cornerstone of the sewing industry, renowned for its simplicity, reliability, and versatility. Since its inception in the 19th century, this machine has evolved significantly, becoming a staple in both industrial and domestic sewing environments. It utilizes a basic lockstitch mechanism that involves a single needle and a lower bobbin, creating tight, secure stitches that are essential for a wide array of fabrics and projects.

One of the primary advantages of the single needle lockstitch machine is its straightforward design. The machine’s operation revolves around one needle that punctures the fabric and forms stitches by interlocking the upper thread from the needle with the lower thread from the bobbin. This process ensures that the stitches are strong and reliable, making it well-suited for sewing everything from delicate fabrics to heavy denim.

The versatility of the single needle lockstitch machine makes it an ideal choice for various applications in garment manufacturing

. Tailors and designers use it for constructing garments, adding seams, hems, and finishes, effectively shaping and molding fabric into wearable art. Its precision allows for the creation of intricate designs, making it invaluable for fashion designers who require flawless and professional results. Furthermore, the machine is widely used for sewing home textiles such as curtains, cushions, and bed linens, showcasing its adaptability across different sectors.single needle lockstitch machine

In the industrial setting, the single needle lockstitch machine plays a critical role in mass production. Its speed and efficiency enable factories to produce a high volume of garments within a short timeframe. Modern iterations of the machine come equipped with advanced features, including automatic threading mechanisms, adjustable stitch lengths, and even computerized controls that enhance productivity while ensuring consistency and quality. This technological advancement has resulted in significant improvements in workflow, allowing manufacturers to meet consumer demand more effectively.

Despite its many benefits, proper maintenance of the single needle lockstitch machine is essential to ensure its longevity and optimal performance. Regular cleaning, oiling, and inspection of parts are necessary to prevent wear and tear, which can lead to costly repairs or downtime. Sewing professionals are encouraged to familiarize themselves with the machine's components and functioning to better troubleshoot any issues that may arise during operation.

Moreover, the single needle lockstitch machine is increasingly being recognized for its role in sustainable fashion practices. With the rising awareness of environmental issues in the textile industry, many designers are opting for this machine to create high-quality, long-lasting garments. The durability of the stitches produced by the lockstitch method means that garments are less likely to unravel, promoting longevity and reducing waste in a throwaway culture.

In conclusion, the single needle lockstitch machine remains a fundamental tool in the sewing world. Its reliability, versatility, and efficiency make it essential for both industrial manufacturers and individual artisans. As the fashion industry moves towards more sustainable practices, the single needle lockstitch machine is likely to maintain its relevance, continuing to empower creators while ensuring that quality is never sacrificed in the quest for speed and efficiency. Hence, it truly stands the test of time as a critical component of garment construction and textile production.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025