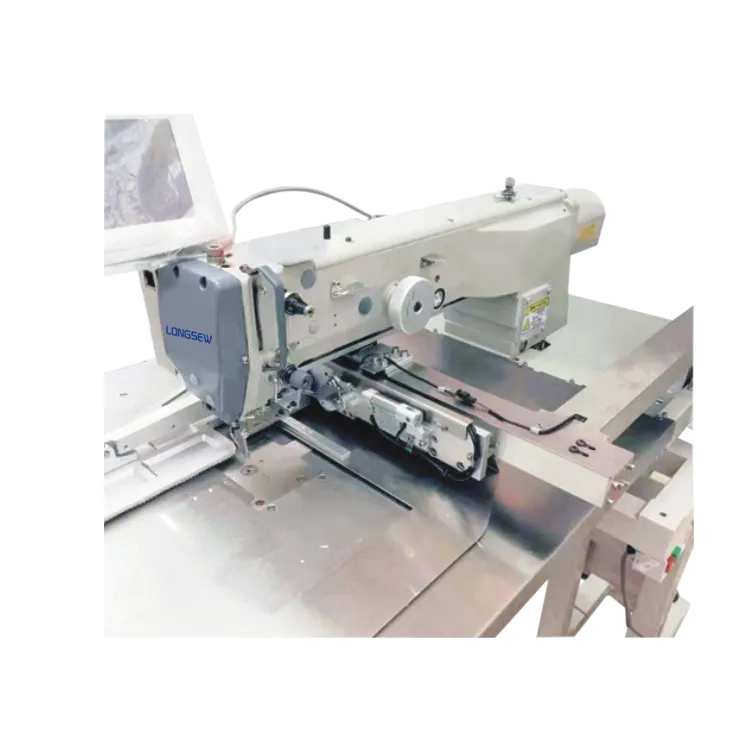

single needle industrial sewing machine

The Single Needle Industrial Sewing Machine A Comprehensive Overview

In the world of textile manufacturing, the single needle industrial sewing machine stands as a cornerstone of production efficiency and quality. Renowned for its versatility and ease of use, this type of sewing machine is widely utilized in various applications, from garment manufacturing to upholstery and more. Understanding its features, advantages, and operational intricacies is essential for those keen on maximizing productivity in their sewing operations.

Features of the Single Needle Industrial Sewing Machine

A single needle industrial sewing machine is characterized by its fundamental design, which incorporates a single needle and bobbin mechanism. This design allows for precision stitching, making it ideal for lightweight to medium-weight fabrics. Some common features include

1. Stitch Types Most single needle machines offer a straight stitch capability, which is essential for most sewing tasks. Advanced models may include zigzag stitching and various decorative stitches. 2. Feed Mechanism The machines typically employ a drop feed or walking foot mechanism, ensuring smooth fabric handling. The walking foot is particularly beneficial when sewing multiple layers or thick materials.

3. Speed Control Many industrial models can operate at high speeds, often exceeding 5,000 stitches per minute. A speed control mechanism allows operators to adjust the speed to suit delicate tasks or detailed work.

4. Construction Built with durability in mind, these machines feature a robust metal frame and high-quality components designed to withstand the rigors of continuous operation.

5. Accessories and Attachments A variety of attachments, such as different presser feet, guides, and stitch plates, expand the machine's functionality, allowing for diverse sewing techniques and applications.

Advantages of Using a Single Needle Industrial Sewing Machine

1. Efficiency High-speed operation coupled with precision enhances productivity in industrial settings. This machine can significantly reduce project turnaround times, beneficial for businesses that rely on fast production cycles.

single needle industrial sewing machine

2. Quality of Stitching The single needle system provides consistent and high-quality stitching, which is vital for maintaining product standards in the fashion industry and other textile operations.

3. Ease of Use The straightforward mechanism of single needle machines allows for easier training of operators. Many users find these machines intuitive, reducing the onboarding time for new personnel.

4. Versatility While primarily used for straight stitches, these machines can handle a range of fabrics, from delicate silks to heavier denim. This versatility makes them an invaluable asset in various production lines.

5. Cost-Effective Compared to multi-needle machines, single needle models generally have a lower purchase price and require less maintenance. This cost-effectiveness is appealing to small and medium-sized enterprises.

Operational Considerations

While single needle industrial sewing machines offer many advantages, operators must be aware of several operational considerations to maximize their potential. Regular maintenance, including oiling and cleaning, is vital to keep the machine in optimal working condition. Operators should also ensure they are using the correct needle size and type for the fabric being sewn to prevent damage and ensure quality results.

Furthermore, proficiency in threading and tension adjustments is essential. Incorrect threading can lead to a range of problems, from broken threads to fabric puckering, which can compromise the final product. Training staff in proper operational techniques can significantly impact overall production quality and efficiency.

Conclusion

The single needle industrial sewing machine remains a staple in the textile production industry, celebrated for its reliability, efficiency, and ease of use. Whether you are a small clothing manufacturer or a large-scale operation, understanding its features and best practices is crucial to achieving the best results. By investing in quality machines and training personnel effectively, businesses can enhance their production capabilities while maintaining high standards in craftsmanship. As the textile industry continues to evolve, the single needle industrial sewing machine will undoubtedly remain integral to its operations, ensuring the seamless blend of tradition and innovation.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025