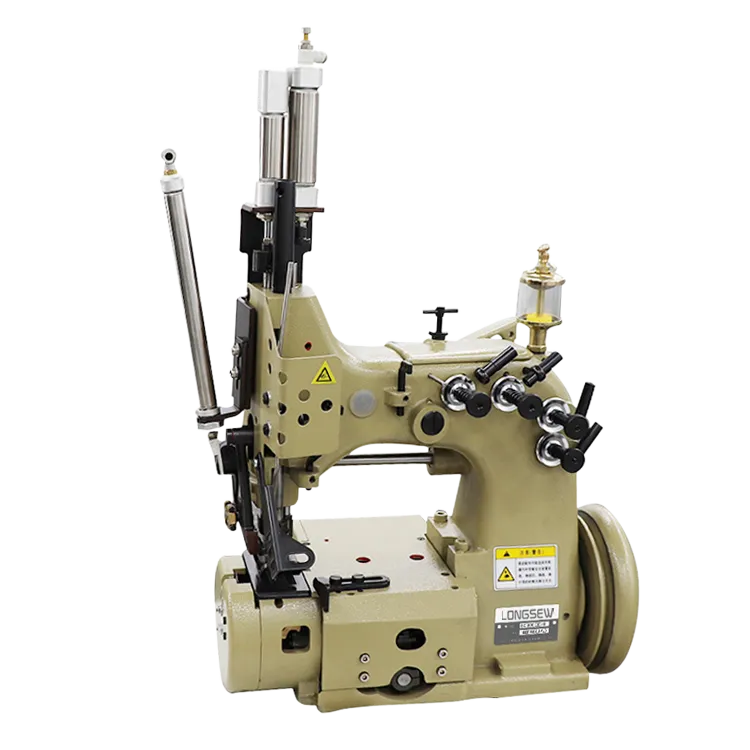

Efficient Single Needle Industrial Sewing Machine for Precision and Durability in Textile Projects

The Versatile Single Needle Industrial Sewing Machine

In the world of textile and apparel manufacturing, the single needle industrial sewing machine holds a revered position. Known for its simplicity and precision, this piece of machinery has been a workhorse in garment factories and workshops for decades. With its straightforward design and powerful performance, it is ideal for a wide range of sewing tasks, making it an essential tool in the fashion industry.

Design and Functionality

The single needle industrial sewing machine is characterized by its single needle and a presser foot that holds the fabric in place while the needle penetrates through it to create stitches. This basic yet effective design allows for various types of stitching, including straight stitch, zigzag stitch, and more specialized stitching techniques. The machine operates with an electric motor, providing the necessary speed and power for efficient sewing.

One of the key advantages of the single needle setup is its ease of use. Even for beginners, mastering the operation of this machine is relatively straightforward. The straightforward threading process and intuitive controls enable users to achieve consistent results with minimal training. This accessibility has made it a popular choice among sewing enthusiasts and professionals alike.

Applications

Single needle industrial sewing machines are incredibly versatile and can be used in a variety of applications. They are widely employed in clothing manufacturing, where they are utilized to sew seams in garments such as shirts, blouses, trousers, and dresses. Their ability to produce high-quality stitches makes them particularly well-suited for garments that require attention to detail and precision.

Beyond clothing, these machines are also used in other sectors, including upholstery, leather goods, and even quilting. In upholstery, single needle machines can efficiently sew heavy fabrics and materials, allowing for the creation of durable furniture. For leather products, these machines can handle thicker materials that demand robust stitching techniques, ensuring longevity and durability in items like bags and shoes.

single needle industrial sewing machine

Benefits of Single Needle Machines

One of the primary benefits of using a single needle industrial sewing machine is its efficiency. These machines are designed to run at high speeds, facilitating the completion of numerous sewing tasks in a short period. This speed is essential in a production environment where meeting deadlines is critical. Moreover, the capacity to work with a variety of fabrics, from lightweight textiles to heavy leathers, adds to their versatility.

Another important aspect is the quality of the stitches produced. The precision that a single needle machine offers ensures that seams are uniform and resilient, which is crucial for the overall quality of the finished product. Additionally, single needle machines tend to be easier to maintain than more complex multi-needle machines, resulting in lower downtime for repairs.

Limitations

While single needle industrial sewing machines are incredibly useful, they do have their limitations. For instance, they can be slower than multi-needle machines when it comes to producing large quantities of complex patterns or decorative stitches. Moreover, their inherent design means they are less suitable for specific tasks that require intricate stitching or multi-directional sewing.

Another consideration is that for higher production demands, businesses may need to invest in multiple machines to handle various tasks, which can raise initial costs. Therefore, while a single needle sewing machine is an excellent investment, it may not cover all aspects of a high-volume sewing operation.

Conclusion

In conclusion, the single needle industrial sewing machine is a cornerstone of the textile industry, appreciated for its simplicity, efficiency, and versatility. It caters to a wide range of sewing tasks across various sectors, from apparel to upholstery, making it an invaluable tool for manufacturers and craftsmen alike. Despite its limitations, its advantages far outweigh them, allowing businesses to maintain high standards of quality and performance. As technology advances, the basic design of these machines continues to evolve, but the fundamental role they play in the sewing process remains unchanged, solidifying their position in the fabric of the textile industry.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025