Single Needle Chain Stitch Machines for Efficient and Precision Sewing Operations

Understanding the Single Needle Chain Stitch Machine

The single needle chain stitch machine is a vital piece of equipment in the textile and garment industries, known for its versatility and efficiency in stitching. This type of sewing machine utilizes a single needle and thread to create a chain stitch, which is a unique form of stitch that allows for stretchy and durable seams, making it ideal for various fabric types.

Key Features and Functionality

One of the defining characteristics of the single needle chain stitch machine is its capability to produce a continuous loop of thread, resulting in a stitch that is both strong and flexible. This is particularly beneficial when working with knitted fabrics or materials that require some degree of stretch, such as t-shirts, leggings, and sportswear. Unlike traditional lockstitch machines, which use two threads (a needle thread and a bobbin thread), the chain stitch uses only one thread that forms a loop on the underside, providing a different texture and finish.

The single needle chain stitch machine is usually equipped with adjustable stitch length and tension settings, allowing operators to customize their stitches according to the fabric type and the specific requirements of the project

. Furthermore, many modern varieties come with automated features that enhance productivity and precision, such as automatic thread trimming and programmable stitch patterns.Advantages of Chain Stitching

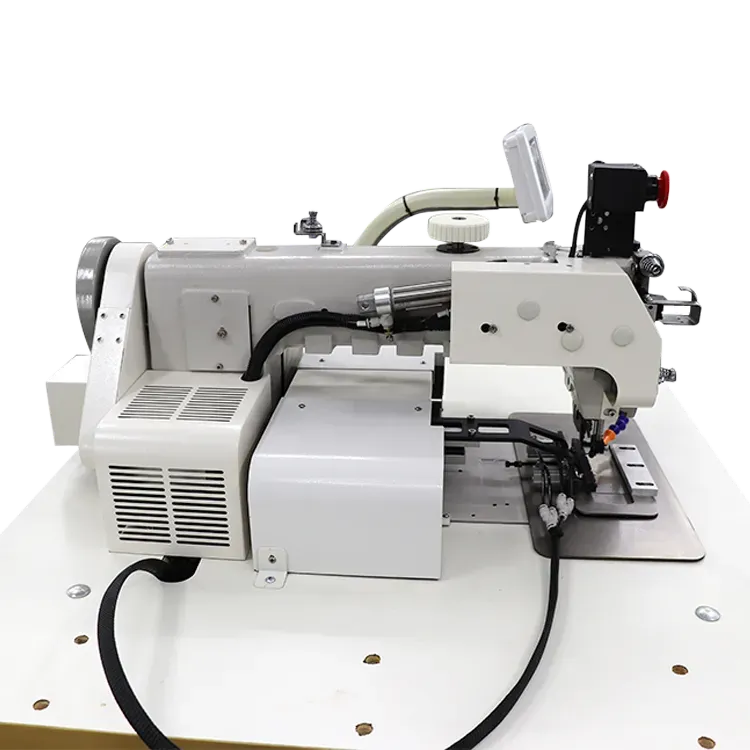

single needle chain stitch machine

One of the significant advantages of using a single needle chain stitch machine is its speed and efficiency. The machine can operate at high speeds, significantly reducing the time taken to complete sewing tasks. Moreover, the chain stitch is known for its resistance to unraveling, making it a reliable option for seams that will be subjected to stress. This quality is paramount in garments intended for active use.

Another benefit is the ease of sewing through multiple layers of fabric. The single needle design allows for straightforward handling of thicker materials, reducing the risk of needle breakage and ensuring a smoother sewing process. This makes it an excellent choice for various applications, from fashion garments to industrial textile products.

Common Applications

In the apparel industry, the single needle chain stitch machine is widely used for constructing seams on knitwear, outerwear, and sports apparel. It is particularly favored in the production of denim jeans, where strong and flexible seams are essential. Beyond clothing, this machine finds applications in upholstering and creating soft furnishings, where robust stitching is required for longevity and durability.

Conclusion

The single needle chain stitch machine is a cornerstone of modern garment production, combining efficiency, versatility, and strength. As the textile industry continues to evolve, the demand for high-quality stitching equipment remains critical. Whether in a small tailoring shop or a large manufacturing facility, understanding the capabilities and applications of the single needle chain stitch machine can greatly enhance workflow and product quality. As technology advances, we can expect further innovations in this essential sewing machine category, paving the way for even greater possibilities in garment construction.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025