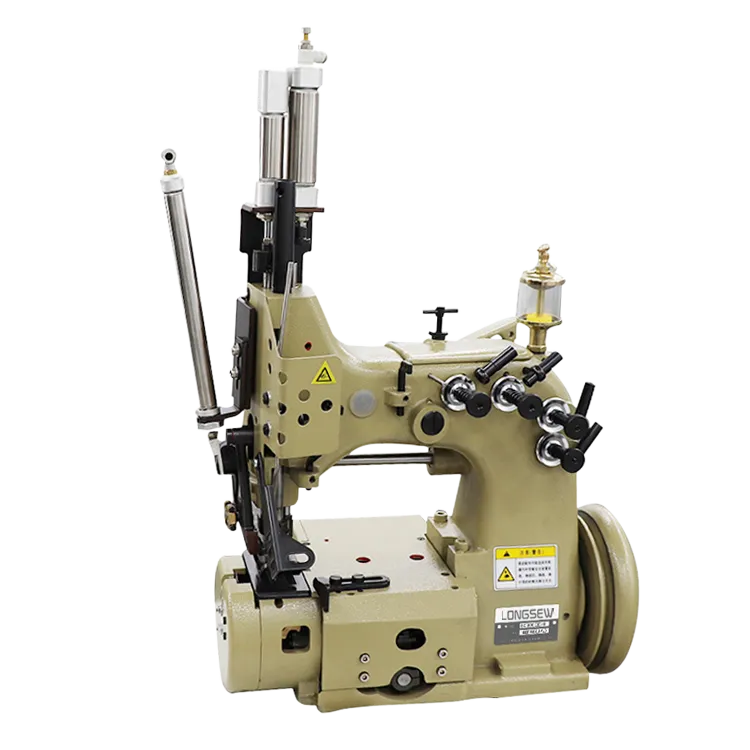

single lock stitch machine

The Single Lock Stitch Machine A Cornerstone of Modern Sewing

The single lock stitch machine is a fundamental piece of equipment that has transformed the world of sewing and garment production. Traditionally utilized in tailoring and garment manufacturing, this machine remains relevant due to its efficiency, ease of use, and the quality of stitches it produces. Understanding its components, benefits, and applications is essential for anyone interested in the textiles and fashion industry.

Components of the Single Lock Stitch Machine

At its core, the single lock stitch machine operates on a simple mechanism, consisting of a needle, a bobbin, a feed mechanism, and a tension system. The needle, usually made of high-quality steel, punctures the fabric to create stitches. The thread from the needle intertwines with a lower thread from the bobbin, forming a lock stitch—hence the name. This interlocking of threads ensures that the seams are strong and secure, making them ideal for various fabrics.

The feed mechanism controls the movement of the fabric. In a basic single lock stitch machine, this is often a manual operation, though many modern variants employ an automatic feed system. The tension system is crucial for balancing the upper and lower threads to produce evenly spaced stitches. Adjusting the tension correctly is vital for achieving high-quality results, as incorrect tension may lead to frayed threads or puckered seams.

Advantages of the Single Lock Stitch Machine

One of the most significant advantages of the single lock stitch machine is its versatility. It is capable of sewing a wide range of fabrics, from lightweight materials like silk to heavier fabrics like denim. This adaptability makes it a staple in both home sewing and industrial settings.

single lock stitch machine

Moreover, the lock stitch produced by this machine is known for its durability. The interlocking threads create a strong seam that can withstand significant stress, ensuring that garments maintain their integrity over time. This robustness makes it especially suitable for high-traffic areas in clothing, like seams and hems.

Another essential benefit of the single lock stitch machine is its efficiency. Compared to other stitching methods, it allows for faster production rates without compromising quality. This aspect is particularly important in commercial contexts where time and cost efficiency is paramount.

Applications in the Textile Industry

The applications of the single lock stitch machine are vast and varied. In the fashion industry, it is widely used for constructing garments, whether they are casual wear, formal attire, or specialty outfits. In addition, it is instrumental in creating home textiles, such as curtains, upholstery, and bedding, ensuring that seams remain secure and aesthetically pleasing.

Beyond fashion, the machine finds applications in technical textiles, such as those used in automotive or medical industries where robust stitching is essential. The capacity to work with thicker threads and multiple fabric layers enhances its functionality in these specialized areas.

Conclusion

The single lock stitch machine is more than just a basic sewing tool; it is a pivotal part of the textile production process. Its durability, versatility, and efficiency have ensured its continued relevance in an ever-evolving industry. For anyone passionate about sewing—whether as a hobbyist or a professional—the single lock stitch machine remains an indispensable asset, embodying the perfect blend of tradition and innovation in the world of fabric and fashion.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025