Exploring the Features and Benefits of Single Lock Stitch Sewing Machines

The Single Lock Stitch Machine An Essential Tool in Textile Manufacturing

The single lock stitch machine is one of the most fundamental sewing machines used in the textile industry. Known for its simplicity, reliability, and versatility, this machine has significantly shaped how garments and textile products are produced. Understanding its design, operation, advantages, and applications can provide valuable insights into the importance of this machine in modern manufacturing processes.

Design and Operation

The single lock stitch machine operates using a straightforward mechanism that involves two threads the upper thread and the lower thread. These threads interlock to form a stitch that is known for its strength and durability. The upper thread is fed from a spool located on the top of the machine, while the lower thread comes from a bobbin housed beneath the needle plate.

When the operator pushes the foot pedal, the machine’s motor powers the needle to move up and down. As the needle penetrates the fabric, it carries the upper thread through, while the bobbin case and feed dog mechanism work to engage the lower thread, creating a locked stitch. This process is repeated as the fabric moves through the machine, allowing for continuous sewing.

Advantages of Single Lock Stitch Machines

One of the primary advantages of the single lock stitch machine is its speed. Capable of sewing several hundred stitches per minute, it enhances productivity in mass production environments. Additionally, the lock stitch is known for its strength, making it suitable for a wide variety of fabrics, particularly when durability is a requirement.

Moreover, this machine is generally more accessible and cost-effective than more complex sewing machines. It allows operators to produce high-quality seams without the need for advanced technical training. This ease of use contributes significantly to its widespread adoption in both industrial settings and home sewing environments.

Another benefit is its versatility. The single lock stitch machine can handle a range of sewing tasks, from basic seams to more intricate designs, including top stitching and decorative elements. It can sew different types of materials, including cotton, polyester, and blends, making it a go-to option for various textile projects.

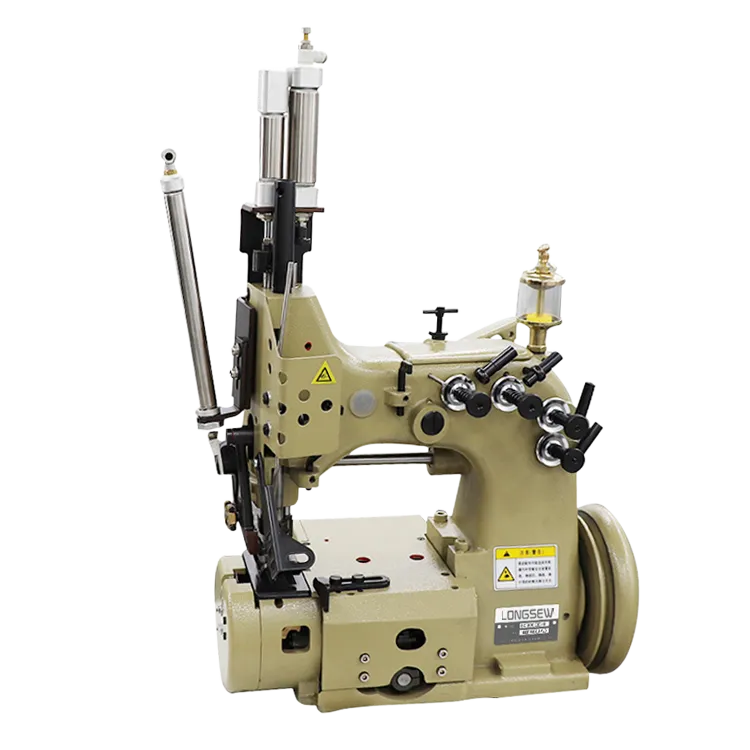

single lock stitch machine

Applications in the Industry

The applications of the single lock stitch machine are vast and varied. In the garment industry, it is used extensively for sewing t-shirts, trousers, skirts, and jackets. Its reliability ensures that finished products meet quality standards, essential for maintaining brand reputation.

In the home sewing sector, hobbyists and professional seamstresses rely on single lock stitch machines to create custom clothing, home décor, and accessories. The machine's ability to produce straight seams efficiently is especially valuable for those engaged in quilting and crafting.

Additionally, the single lock stitch machine plays a vital role in industrial applications, such as upholstery and workwear manufacturing. In these contexts, the strength of the lock stitch is crucial for constructing items that need to withstand rigorous use and environmental stressors.

Innovations and Future Trends

As technology evolves, the single lock stitch machine continues to adapt. Modern machines may incorporate computerized systems that enhance precision and efficiency, allowing for programmable stitch patterns and automatic tension adjustments. These innovations not only streamline production but also enhance the quality of the finished product.

Sustainability is also becoming increasingly relevant in textile manufacturing. As consumers seek more environmentally friendly products, the demand for machines that can efficiently work with sustainable materials is rising. The adaptability of single lock stitch machines positions them well to meet these changing market demands.

Conclusion

The single lock stitch machine remains an indispensable tool in the textile industry. Its blend of speed, strength, and versatility makes it ideal for a wide range of sewing applications. As innovations continue to improve these machines, they will undoubtedly maintain their significance in both industrial and home settings, paving the way for a sustainable and efficient future in textile manufacturing.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025