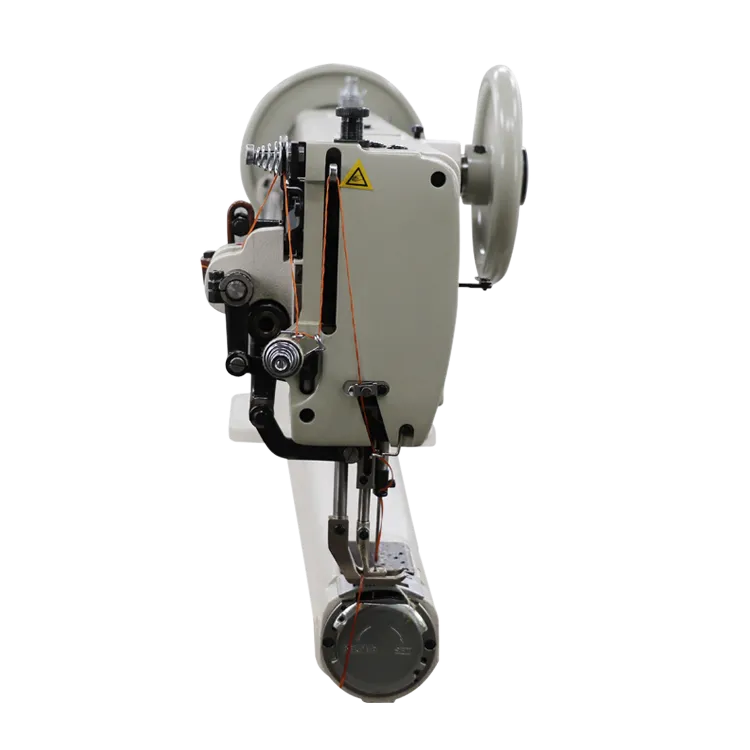

single needle lock stitch machine with motor

The Single Needle Lock Stitch Machine with Motor A Comprehensive Overview

In the world of textile manufacturing, efficiency and precision are paramount. Among the myriad of sewing machines available, the single needle lock stitch machine with motor stands out as a quintessential tool for both professional tailors and industrial producers. This article aims to delve into the functionality, applications, and advantages of this remarkable sewing machine.

Understanding the Single Needle Lock Stitch Machine

The single needle lock stitch machine is engineered for a variety of sewing tasks, utilizing a single needle to create a secure stitch that holds fabric layers together effectively. The term lock stitch refers to the method of stitching where the needle thread and the bobbin thread interlock to form a durable seam. This type of stitch is widely regarded for its strength and versatility, making it suitable for a broad range of materials including cotton, denim, and synthetic fabrics.

The integration of a motor into this sewing machine enhances its usability and efficiency. Most modern machines come equipped with an electric motor that provides consistent power, resulting in smoother operation and the ability to achieve higher sewing speeds. This is particularly beneficial in commercial settings where time is money, as it allows for faster production without compromising stitch quality.

Applications in Various Industries

The single needle lock stitch machine is incredibly versatile, finding applications across various sectors. In the apparel industry, it is utilized in the construction of garments, ensuring that seams are not only strong but also aesthetically pleasing. Tailors appreciate its precision when working on intricate designs and detailed patterns, as the single needle allows for better maneuverability around curves and corners.

single needle lock stitch machine with motor

In addition to apparel, this machine is indispensable in home furnishings where it is used to sew curtains, cushions, and upholstery. Its ability to work with heavy fabrics makes it a preferred choice for many interior designers and manufacturers. Furthermore, the automotive industry employs single needle lock stitch machines for stitching seat covers and interiors, ensuring durability in high-wear items.

Advantages of Using a Motorized Version

The motorized version of the single needle lock stitch machine provides several notable benefits. Firstly, the electric motor facilitates a higher stitching speed compared to manual counterparts, which significantly boosts productivity. Additionally, it reduces the physical strain on operators, as they do not have to pedal manually, allowing for longer periods of work with less fatigue.

Moreover, modern motorized machines often include features such as adjustable speed settings, allowing users to customize their sewing experience according to the project at hand. This adaptability is critical when dealing with varying fabric types and thicknesses, providing flexibility that is essential in today’s fast-paced production environments.

Conclusion

The single needle lock stitch machine with motor is an invaluable asset in textile and garment manufacturing. Its efficiency, versatility, and the durability of the lock stitch make it an indispensable tool for tailors and manufacturers alike. As technology continues to evolve, these machines will likely incorporate even more advanced features, aiding in streamlining production processes and enhancing the overall quality of sewn products. For anyone involved in the sewing industry, investing in a high-quality single needle lock stitch machine with an integrated motor can lead to significant improvements in both output and craftsmanship.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025