sewing machine used for leather

The Essential Guide to Sewing Machines for Leather A Comprehensive Overview

When it comes to crafting leather goods, whether for fashion, upholstery, or accessories, having the right tools is crucial. One of the most important tools for any leatherworker is a sewing machine specifically designed for leather. Using an ordinary sewing machine can lead to frustration, poor stitching quality, and damage to both the machine and the material. In this article, we will explore the types of sewing machines suited for leather, their features, and tips for selecting the right one for your projects.

Types of Sewing Machines for Leather

1. Walking Foot Sewing Machines These machines are equipped with a walking foot mechanism which allows the presser foot, needle, and feed dogs to move together in synchronization. This is essential when working with leather, as it ensures that the top and bottom layers feed evenly through the machine. The walking foot minimizes the risk of stretching or shifting, resulting in a more precise stitch.

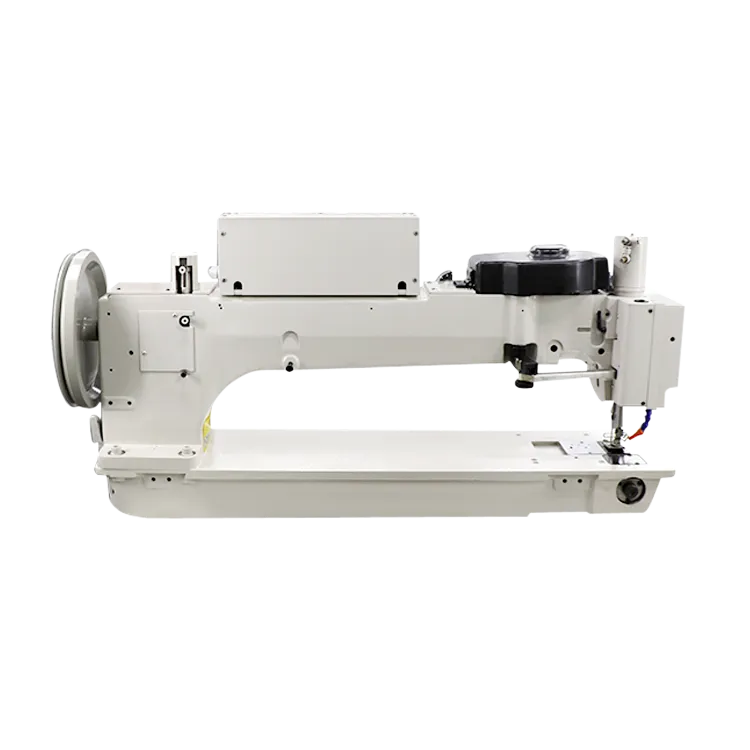

2. Industrial Sewing Machines For those serious about leatherworking, industrial sewing machines are a fantastic investment. They are robust, designed for heavy materials, and can handle multiple layers of leather with ease. Industrial machines often have powerful motors and high-speed capabilities, making them suitable for large-scale production. Brands like Juki, Brother, and Consew produce top-notch industrial machines ideal for leather.

3. Home Sewing Machines with Heavy-Duty Features Not everyone needs an industrial machine. Many home sewing machines now come with heavy-duty capabilities that allow them to sew leather effectively. Look for machines that feature a strong motor, a heavy-duty needle, and adjustable presser foot pressure. Models from brands like Singer and Janome can be a great starting point for leather crafting at home.

Key Features to Consider

When selecting a sewing machine for leather, consider the following features

- Needle Size and Type Leather needles have a wedge-shaped point that allows them to penetrate thick material without causing damage. Ensure your machine is compatible with heavy-duty or specialized leather needles.

- Stitch Types Look for a machine that offers various stitch types, including straight and zigzag stitches. Some projects may require decorative stitching, so versatility is important.

sewing machine used for leather

- Motor Strength The motor strength determines how well the machine will perform with thick leather. A machine with a stronger motor will be more capable of handling heavy materials without skipping stitches.

- Feed Mechanism As mentioned earlier, a walking foot is beneficial. Other features like a compound feed system or an adjustable feed can also help manage how material is guided through the machine.

Tips for Sewing Leather

1. Use the Right Thread Polyester or nylon threads are best for leather as they are strong and can withstand the stress that leather projects often experience.

2. Test Before You Sew Always do a test stitch on a scrap piece of leather to ensure that the tension, stitch length, and needle are appropriate for your material.

3. Cut Carefully Use rotary cutters or sharp scissors designed for heavy materials to ensure clean edges, as rough cuts can affect the quality of the final product.

4. Mind the Speed When sewing leather, go slow, especially around curves and corners. This allows for better control and more accurate stitching.

5. Keep Your Machine Clean Leather sewing projects can create more lint and debris. Regular maintenance will ensure your machine operates smoothly over time.

Conclusion

Investing in the right sewing machine for leather can transform your crafting experience. Whether you choose a walking foot machine, an industrial machine, or a heavy-duty home model, understanding the key features and proper techniques will enhance your results. With the right tools and knowledge, you can create stunning leather pieces that showcase your craftsmanship and creativity. Happy sewing!

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025