Feb . 14, 2025 03:49

Back to list

q bag baffle sew

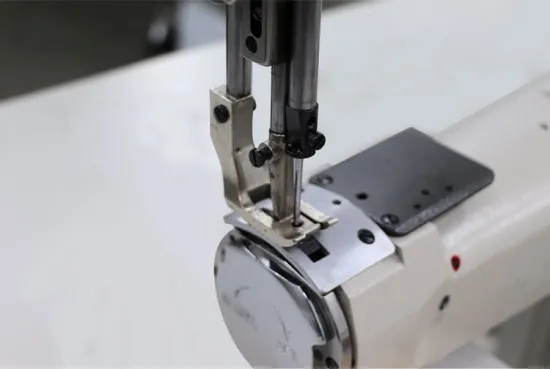

Navigating the world of sewing machines can be intricate, especially when leather, a robust and distinctive material, is involved. For enthusiasts and professionals aiming to work with leather, selecting a sewing machine that complements this sturdy fabric is crucial.

The experience of using a sewing machine that can sew through leather extends beyond the machine itself. Trustworthy manufacturers are pivotal, offering comprehensive manuals, robust customer support, and accessible repair services. Brands such as Juki, Pfaff, and Consew have cultivated a reputation for delivering not just machines, but a lasting relationship with their users. Their commitment to quality and service echoes through user reviews and professional recommendations. Sewing leather also calls for a thorough understanding of various threads and tensions. Polyester thread is often recommended for its durability and ability to withstand the wear that leatherwork typically endures. The integration of these threads in machines specialized for leather ensures that every project is completed with the highest standard of craftsmanship. The narratives shared by users in diverse forums and review platforms paint a vivid picture of personal experiences and challenges faced in leather sewing. This grass-roots knowledge, shared among a global community, amplifies the relevance and utility of investing in a suitable sewing machine for leather. Operators of these machines narrate stories of projects ranging from leather fashion accessories to intricate upholstery, each emphasizing the machine's role in achieving professional-grade results. An authoritative voice on the subject, engineers and experts who design these machines, often highlight the innovative features that are specifically engineered for leather. From vibration control mechanics to heat dissipation systems, these elements play an essential role in prolonging the machine's lifespan and ensuring optimal operation. Choosing the right sewing machine for leather is not merely a purchase, but a commitment to quality craftsmanship, reliability, and the pursuit of artistic expression. As technology continues to meld with tradition in the realm of textile crafts, these machines will undoubtedly remain at the fore of leatherworking innovation. For consumers looking to delve into this rewarding craft, understanding these key elements ensures a seamless journey in creating masterpieces that stand the test of leather’s timeless allure.

The experience of using a sewing machine that can sew through leather extends beyond the machine itself. Trustworthy manufacturers are pivotal, offering comprehensive manuals, robust customer support, and accessible repair services. Brands such as Juki, Pfaff, and Consew have cultivated a reputation for delivering not just machines, but a lasting relationship with their users. Their commitment to quality and service echoes through user reviews and professional recommendations. Sewing leather also calls for a thorough understanding of various threads and tensions. Polyester thread is often recommended for its durability and ability to withstand the wear that leatherwork typically endures. The integration of these threads in machines specialized for leather ensures that every project is completed with the highest standard of craftsmanship. The narratives shared by users in diverse forums and review platforms paint a vivid picture of personal experiences and challenges faced in leather sewing. This grass-roots knowledge, shared among a global community, amplifies the relevance and utility of investing in a suitable sewing machine for leather. Operators of these machines narrate stories of projects ranging from leather fashion accessories to intricate upholstery, each emphasizing the machine's role in achieving professional-grade results. An authoritative voice on the subject, engineers and experts who design these machines, often highlight the innovative features that are specifically engineered for leather. From vibration control mechanics to heat dissipation systems, these elements play an essential role in prolonging the machine's lifespan and ensuring optimal operation. Choosing the right sewing machine for leather is not merely a purchase, but a commitment to quality craftsmanship, reliability, and the pursuit of artistic expression. As technology continues to meld with tradition in the realm of textile crafts, these machines will undoubtedly remain at the fore of leatherworking innovation. For consumers looking to delve into this rewarding craft, understanding these key elements ensures a seamless journey in creating masterpieces that stand the test of leather’s timeless allure.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025