Feb . 16, 2025 02:12

Back to list

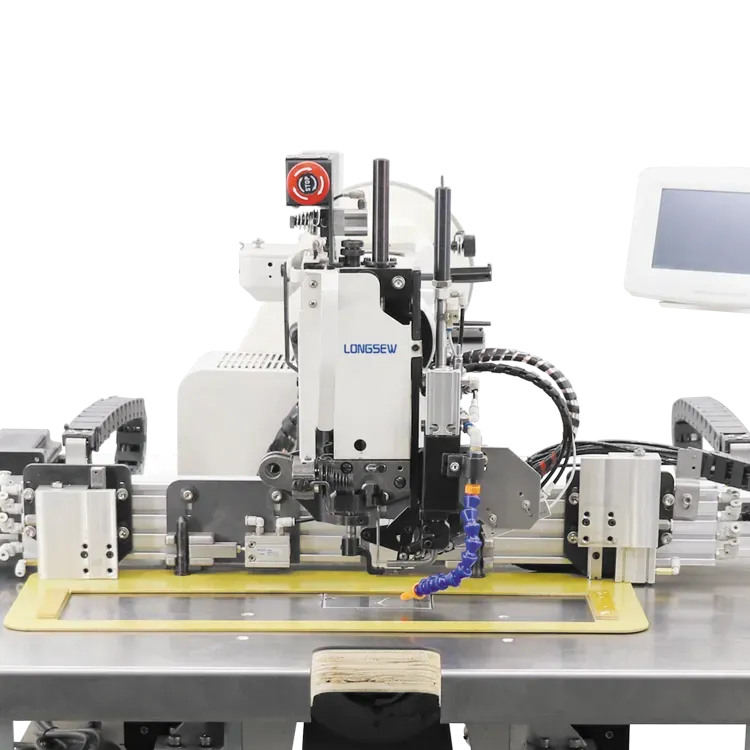

FIBC Bag / Jumbo Bag / Big Bag Double Needles Chain Stitch Sewing Machine 80700C/ 80700CD / 80700CD4H

Navigating the intricacies of sewing marine-grade vinyl for boats demands precision, quality equipment, and an understanding of the material's unique properties. Boat vinyl, renowned for its durability and resistance to harsh marine environments, requires a specialized sewing machine capable of handling its thickness and texture. For marine upholsterers and hobbyists alike, finding the right sewing machine can significantly impact the quality and longevity of their projects.

For those with professional aspirations, or dedicated home enthusiasts, investing in a machine with advanced features like automatic thread cutting, needle positioning, and programmable patterns can elevate the sewing experience. These features enhance efficiency and precision, allowing users to focus more on creativity and less on manual adjustments. Expert recommendations often highlight brands and models known for their resilience and adaptability in marine applications. Juki, Sailrite, and Pfaff, for instance, are well-regarded within the marine upholstery community for their specialized machines designed to tackle heavy-duty fabrics like boat vinyl. Engaging with communities and forums dedicated to marine sewing provides invaluable insights and firsthand experiences, enriching one's understanding of which models deliver consistent results. Trusting a manufacturer's legacy, technical support, and warranty options further bolster confidence in chosen equipment. A company willing to stand behind its product through comprehensive support and service ensures that users are not left navigating machine issues alone, reinforcing trust and satisfaction in the purchase. Ultimately, selecting the right sewing machine for boat vinyl is a blend of technical considerations and practical usage sensations. The right machine empowers users to transform durable vinyl into customized, high-performing upholstery that enhances both the aesthetic and functional qualities of their boats. By focusing on tailored machine features, robust construction, and the backing of a reliable manufacturer, marine upholsterers can ensure their projects withstand the test of time and water.

For those with professional aspirations, or dedicated home enthusiasts, investing in a machine with advanced features like automatic thread cutting, needle positioning, and programmable patterns can elevate the sewing experience. These features enhance efficiency and precision, allowing users to focus more on creativity and less on manual adjustments. Expert recommendations often highlight brands and models known for their resilience and adaptability in marine applications. Juki, Sailrite, and Pfaff, for instance, are well-regarded within the marine upholstery community for their specialized machines designed to tackle heavy-duty fabrics like boat vinyl. Engaging with communities and forums dedicated to marine sewing provides invaluable insights and firsthand experiences, enriching one's understanding of which models deliver consistent results. Trusting a manufacturer's legacy, technical support, and warranty options further bolster confidence in chosen equipment. A company willing to stand behind its product through comprehensive support and service ensures that users are not left navigating machine issues alone, reinforcing trust and satisfaction in the purchase. Ultimately, selecting the right sewing machine for boat vinyl is a blend of technical considerations and practical usage sensations. The right machine empowers users to transform durable vinyl into customized, high-performing upholstery that enhances both the aesthetic and functional qualities of their boats. By focusing on tailored machine features, robust construction, and the backing of a reliable manufacturer, marine upholsterers can ensure their projects withstand the test of time and water.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025