Jan . 19, 2025 01:05

Back to list

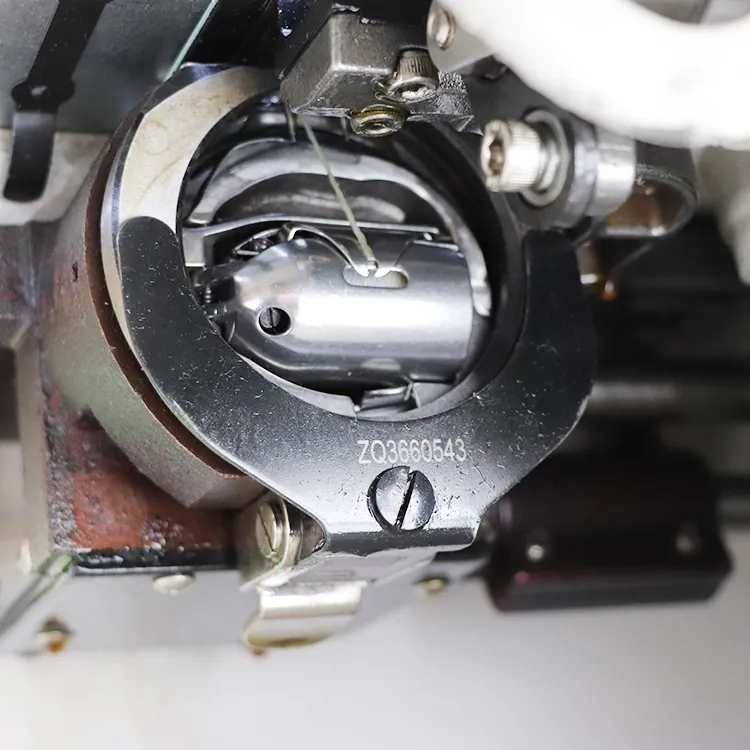

sewing locking machine

The world of sewing has evolved significantly over the years, and one innovation that has dramatically advanced the craft is the sewing locking machine. For those who are enthusiasts or professionals in the textile industry, understanding the mechanics and benefits of this machine can enhance productivity and fabric craftsmanship.

Trustworthiness in sewing locking machines can often be assessed through customer reviews and brand reputation. Leading manufacturers frequently invest in research and development to enhance the reliability of their machines, often incorporating advanced technologies such as automatic thread cutters and digital displays for ease of use. These enhancements provide users with assurance in terms of performance consistency and the ability to tackle complex sewing projects. For product researchers and developers, the future of sewing locking machines holds exciting potential. Continuous innovations such as energy-efficient motors, eco-friendly components, and smarter automation options are paving the way for sustainable sewing practices. Such developments are particularly appealing to environmentally-conscious designers looking to reduce the carbon footprint of their production processes while maintaining high-quality output. Exploration into the cross-functional capabilities of sewing locking machines also points toward their integration in educational settings. Sewing schools and workshops often utilize these machines as they offer students a hands-on experience with industrial-grade stitching, preparing them for careers in fashion and textile manufacturing. As such, sewing locking machines have become a core component of professional training in the industry. In conclusion, sewing locking machines are a valuable asset for both casual sewers and industry professionals. Their robust design, reliability, and ability to produce high-quality stitches make them indispensable in creating durable and aesthetically pleasing fabrics. By choosing a reputable brand and adhering to expert maintenance advice, users can ensure they maximize their investment in this valuable tool. The continued innovation in this sector promises even greater advancements, making sewing locking machines more essential than ever in the modern fabric arts and industrial sewing landscapes.

Trustworthiness in sewing locking machines can often be assessed through customer reviews and brand reputation. Leading manufacturers frequently invest in research and development to enhance the reliability of their machines, often incorporating advanced technologies such as automatic thread cutters and digital displays for ease of use. These enhancements provide users with assurance in terms of performance consistency and the ability to tackle complex sewing projects. For product researchers and developers, the future of sewing locking machines holds exciting potential. Continuous innovations such as energy-efficient motors, eco-friendly components, and smarter automation options are paving the way for sustainable sewing practices. Such developments are particularly appealing to environmentally-conscious designers looking to reduce the carbon footprint of their production processes while maintaining high-quality output. Exploration into the cross-functional capabilities of sewing locking machines also points toward their integration in educational settings. Sewing schools and workshops often utilize these machines as they offer students a hands-on experience with industrial-grade stitching, preparing them for careers in fashion and textile manufacturing. As such, sewing locking machines have become a core component of professional training in the industry. In conclusion, sewing locking machines are a valuable asset for both casual sewers and industry professionals. Their robust design, reliability, and ability to produce high-quality stitches make them indispensable in creating durable and aesthetically pleasing fabrics. By choosing a reputable brand and adhering to expert maintenance advice, users can ensure they maximize their investment in this valuable tool. The continued innovation in this sector promises even greater advancements, making sewing locking machines more essential than ever in the modern fabric arts and industrial sewing landscapes.

Previous:

Next:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025